Metal etching solution and etching method for copper/molybdenum film

A technology of metal etching and film layer, which is applied in the field of metal etching solution, can solve the problems of high cost, complex composition, high cost of raw materials, etc., and achieve the effect of wide application range, simple composition and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

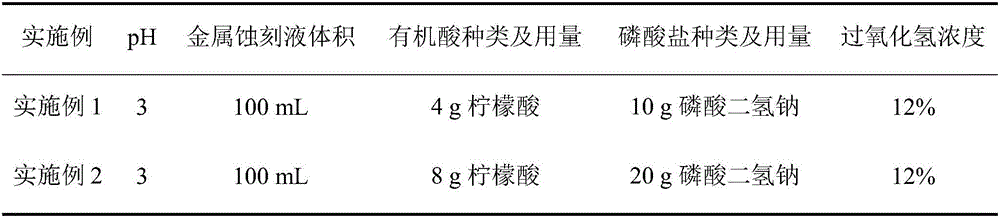

Examples

Embodiment 3

[0034] This embodiment provides an etching method for the copper / molybdenum film layer with the metal etching solution described in the above-mentioned embodiments 1 and 2, that is, the copper / molybdenum film layer is in contact with the above-mentioned metal etching solution.

[0035] Specifically, the device with the copper / molybdenum film layer is contacted with the metal etching solution, for example, the device with the copper / molybdenum film layer can be immersed in the metal etching solution.

[0036] The above etching process is preferably carried out at 30°C-35°C.

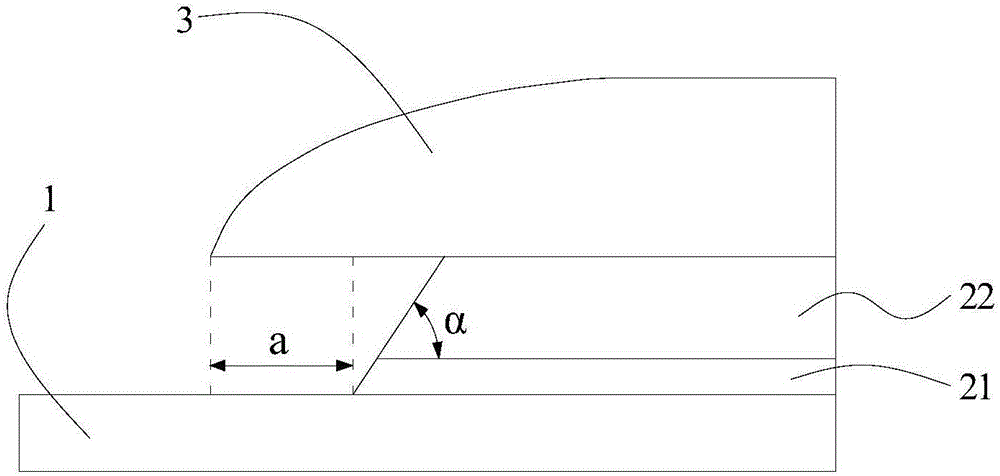

[0037] refer to figure 1 , the device includes a substrate 1, and a barrier film 21, a copper wiring 22, and a resist layer 3 are sequentially stacked on the substrate 1, wherein the combination of the barrier film 21 and the wiring 22 is the copper copper wire described in the embodiment of the present invention. / molybdenum film layer.

[0038] It is worth noting that a good metal etchant should make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com