High-temperature-resistant heat-insulation heat preservation cover for SCR automobile exhaust system and manufacturing method of high-temperature-resistant heat-insulation heat preservation cover

An automobile exhaust system, heat insulation technology, applied in the direction of exhaust devices, chemical instruments and methods, vehicle parts, etc., can solve the problems of inconvenient assembly, complex structure, high cost, etc., achieve reduced assembly procedures, simple operation, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

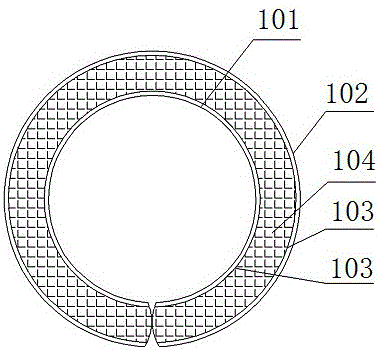

[0036] Such as figure 1The shown one is a high-temperature heat-resistant and heat-insulating cover for the exhaust system of an SCR automobile, which is mainly used in the SCR after-treatment system. Since the SCR catalytic converter is a very important part, it not only bears the responsibility of reducing the exhaust gas in the engine. At the same time, it also acts as a muffler, that is, the catalytic converter has the function of integrating the SCR catalytic converter and the exhaust muffler, but it needs to maintain a high temperature in the SCR catalytic converter. If the temperature is too low, it will It affects the effect of catalytic conversion, so it is necessary to wrap the SCR catalytic converter with a heat-resistant heat insulation cover to maintain a higher temperature for the SCR catalytic converter. The high temperature resistant heat insulation cover of the present invention is mainly used to include a housing and a fixing member for fixing the housing. Th...

Embodiment 2

[0038] A kind of heat-resistant and heat-insulating cover for SCR automobile exhaust system, such as figure 1 As shown, the structure is the same as that of Embodiment 1, and a continuous basalt fiber mesh cloth 103, a continuous basalt fiber needle felt 104, glass fiber chopped strands and an adhesive are arranged between the housing inner wall 101 and the housing outer wall 102, and the mass is Percentage, the continuous basalt fiber mesh 103 is set to 8%, the continuous basalt fiber needle felt 104 is set to 81%, the glass fiber chopped yarn is 7%, the adhesive is set to 4%, and the adhesive is set to ring Oxygen resin, the shell is set to aluminum plate, and the thickness is set to 0.2mm. Such a high temperature resistant heat insulation cover is flame retardant, with a heat reflectivity of 93%, a maximum heat-resistant temperature of 880°C, and a thermal conductivity of 0.051 W. / m.k, its heat insulation performance is excellent, which meets the requirements of SCR cataly...

Embodiment 3

[0040] A kind of heat-resistant and heat-insulating cover for SCR automobile exhaust system, such as figure 1 As shown, the structure is the same as that of Embodiment 1, and a continuous basalt fiber mesh cloth 103, a continuous basalt fiber needle felt 104, glass fiber chopped strands and an adhesive are arranged between the housing inner wall 101 and the housing outer wall 102, and the mass is Percentage, continuous basalt fiber mesh 103 is set to 5%, continuous basalt fiber needle felt 104 is set to 87%, glass fiber chopped yarn 5%, adhesive is set to 3%, adhesive is set to epoxy resin, The shell is made of aluminum plate, and the thickness is set to 0.09mm. Such a high-temperature heat-resistant and heat-insulating cover is flame-retardant, with a heat reflectivity of 96%, a maximum heat-resistant temperature of 900°C, and a thermal conductivity of 0.048 W / m.k. Its heat insulation performance is excellent, which meets the requirements of SCR catalytic converter heat prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com