Super-low field nano magnetic probe, manufacturing method thereof and applications

An ultra-low field, magnetic probe technology, applied in scanning probe technology, scanning probe microscopy, measurement devices, etc., can solve problems such as laborious, time-consuming, and impact on applications, and achieve common equipment and simple components. , powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

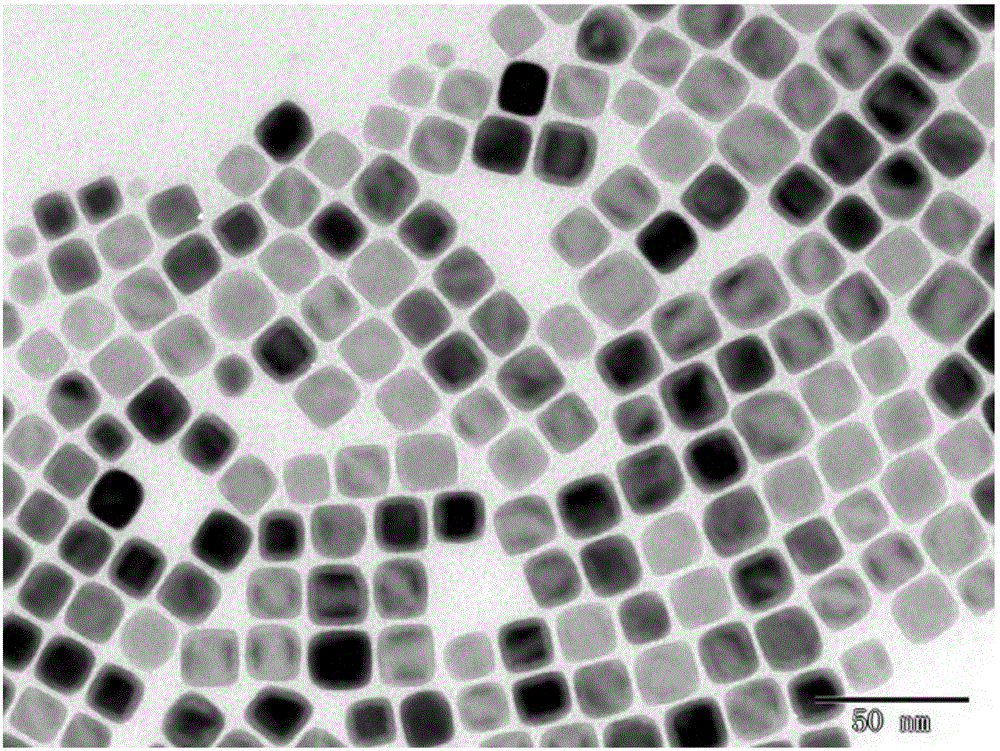

[0055]1. Add 2mmol of iron acetylacetonate, 6mmol of oleic acid, 6mmol of oleylamine and 20ml of octadecene into a 150ml three-necked flask, stir and mix evenly at 1600rpm / min, vacuumize at 80°C for 30min, then fill with nitrogen, and then heat up to 200°C ℃, keep it for 30min, then raise the temperature to 300℃, reflux for 30min, remove the heat source, cool to room temperature, then add an appropriate amount of ethanol, centrifuge at 6000r / min for 10min, take the precipitate, then add an appropriate amount of cyclohexane to dissolve the product, Centrifuge again at 6000r / min for 10min, take the upper liquid, repeat the ethanol precipitation / cyclohexane dispersion process 3 times, and finally use the prepared magnetic nanoparticles directly for the next experiment, or disperse them in cyclohexane and store them in a sample bottle and placed in a refrigerator at 4°C.

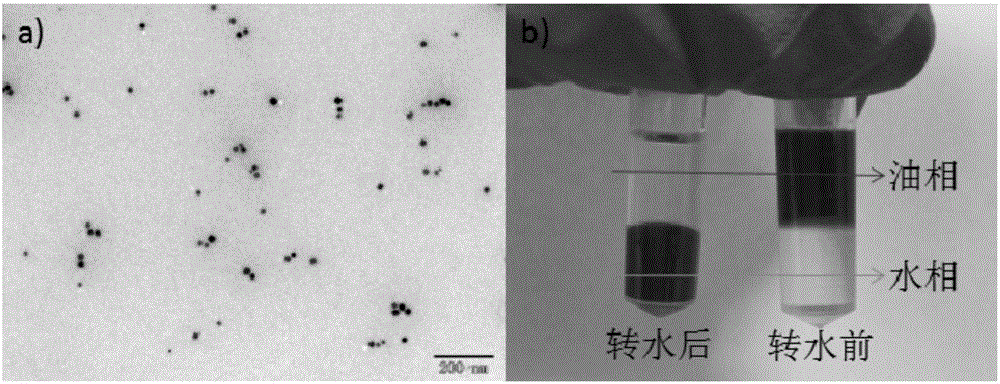

[0056] 2. Add 100mg of DHCA (3,4-dihydroxyhydrocinnamic acid) and 12ml of THF to a 100ml four-necked flask (1...

Embodiment 2

[0060] Add 2mmol of iron acetylacetonate, 6mmol of oleic acid, 6mmol of oleylamine and 20ml of octadecene into a 150ml three-necked flask, stir and mix evenly at 1600rpm / min, vacuumize at 80°C for 30min, then fill with nitrogen, and then heat up to 200°C. Keep it for 2h, then raise the temperature to 300°C, reflux for 1h, remove the heat source, cool to room temperature, then add an appropriate amount of ethanol, centrifuge at 6000r / min for 10min, take the precipitate, then add an appropriate amount of cyclohexane to dissolve the product, 6000r / min Min was centrifuged again for 10 min, the upper layer liquid was taken, and the process of ethanol precipitation / cyclohexane dispersion was repeated three times, and finally the prepared magnetic nanoparticles were directly used in the next experiment.

[0061] Subsequently, add 50mgDHCA (3,4-dihydroxyhydrocinnamic acid) and 6ml of THF to a 50ml four-necked flask (19*14×3), and connect the four ports of the four-necked flask to therm...

Embodiment 3

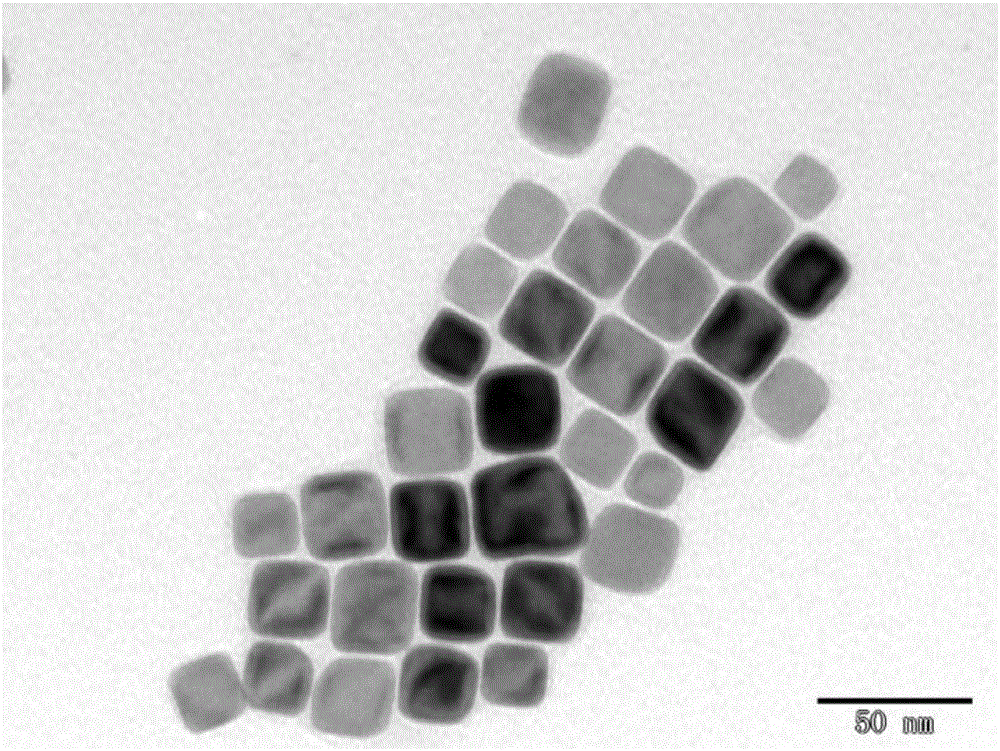

[0065] Add 2mmol of iron acetylacetonate, 6mmol of oleic acid, 6mmol of oleylamine and 20ml of octadecene into a 150ml three-necked flask, stir and mix evenly at 1600rpm / min, vacuumize at 80°C for 30min, then fill with nitrogen, and then heat up to 200°C. Keep it for 15 minutes, then raise the temperature to 300°C, reflux for 1 hour, remove the heat source, cool to room temperature, then add an appropriate amount of ethanol, centrifuge at 6000r / min for 10min, take the precipitate, then add an appropriate amount of cyclohexane to dissolve the product, 6000r / min Centrifuge again for 10 min, take the upper layer, repeat the ethanol precipitation / cyclohexane dispersion process 3 times, and finally disperse the prepared magnetic nanoparticles in cyclohexane and store them in a sample bottle and place them in a refrigerator at 4°C .

[0066] The dynamic light scattering (DLS) of the magnetic nanoparticle prepared by this embodiment measures the histogram of the hydrodynamic particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com