Preparation method for nickel-doped nano-stannum oxide (Ni-doped nano-SnO2) powder

A nano-tin oxide and powder technology, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of miscellaneous products, poor mechanical properties, and low binding force, etc., achieve low hydrothermal reaction temperature, shorten synthesis cycle, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of precursor solution

[0022] Weigh 0.637g SnCl 4 ·5H 2 O and 5.287g Ni(NO 3 ) 2 ·6H 2 O(n Sn :n Ni The molar ratio is 1:10), added to 100mL deionized water to dissolve completely, and pipetted into a 100mL volumetric flask with a glass rod to constant volume, and configured as a transparent precursor solution with a total concentration of 0.2mol / L.

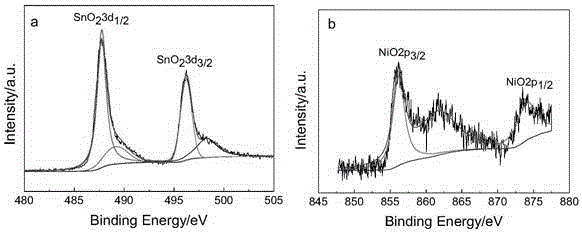

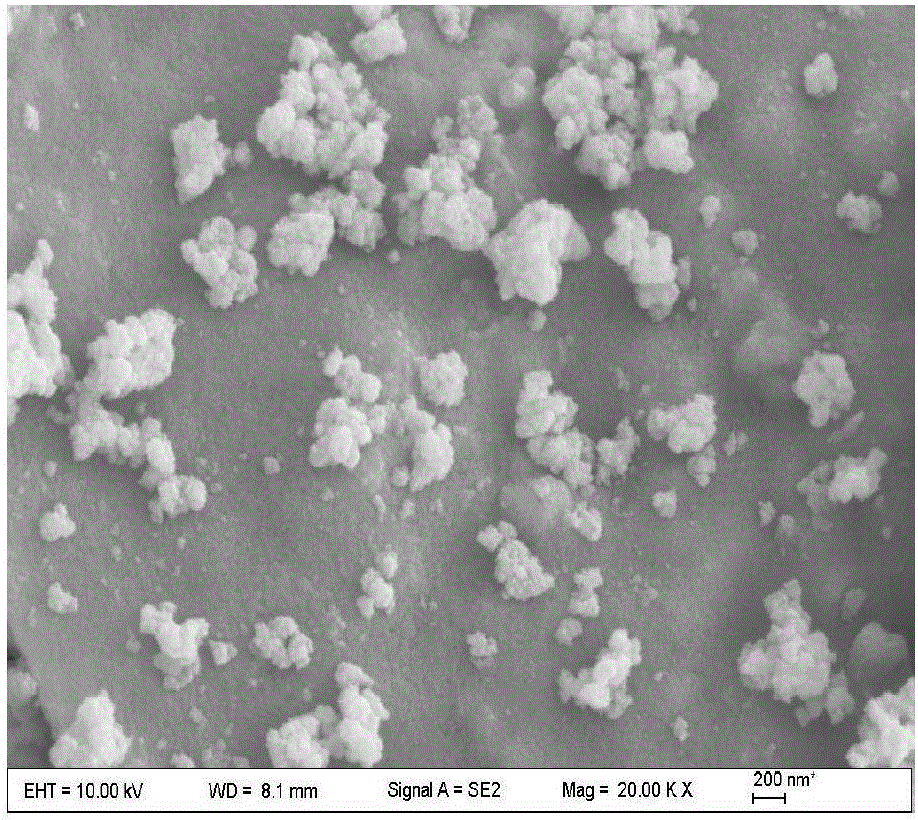

[0023] (2) Preparation of nickel-doped nano-tin oxide powder

[0024] Introduce 0.2mol / L sodium hydroxide solution dropwise into the precursor solution placed in magnetic stirring, adjust the pH value of the mixed solution to 8, form a transparent solution, continue magnetic stirring for 1h, and use the mixed solution obtained by stirring The glass rod was introduced into the reaction kettle, and a white precipitate was obtained after hydrothermal reaction at 180°C for 24 hours. The precipitate was repeatedly washed with ethanol and deionized water to remove excess ions, and dried at 80°C for 2 hour...

Embodiment 2

[0026] (1) Preparation of precursor solution

[0027] Weigh 4.854g SnCl 4 ·5H 2 O and 13.42g Ni(NO 3 ) 2 ·6H 2 O(n Sn :n Ni The molar ratio is 3:10), added to 100mL deionized water to dissolve completely, and pipetted into a 100mL volumetric flask with a glass rod to make up a transparent precursor solution with a total concentration of 0.6mol / L.

[0028] (2) Preparation of nickel-doped nano-tin oxide powder

[0029] Introduce 0.1mol / L sodium hydroxide solution dropwise into the precursor solution placed in magnetic stirring, adjust the pH value of the mixed solution to 9 to form a transparent solution, continue magnetic stirring for 2h, and use the mixed solution obtained by stirring The glass rod was introduced into the reaction kettle, and a white precipitate was obtained after hydrothermal reaction at 150°C for 20 hours. The precipitate was repeatedly washed with ethanol and deionized water to remove excess ions, and dried at 100°C for 4 hours to obtain nickel-doped...

Embodiment 3

[0031] (1) Preparation of precursor solution

[0032] Weigh 4.675g SnCl 4 ·5H 2 O and 7.754g Ni(NO 3 ) 2 ·6H 2 O(n Sn :n Ni The molar ratio is 5:10), added to 100ml deionized water to dissolve completely, and pipetted into a 100mL volumetric flask with a glass rod to constant volume, and configured as a transparent precursor solution with a total concentration of 0.4mol / L.

[0033] (2) Preparation of nickel-doped nano-tin oxide powder

[0034] Introduce 0.3mol / L sodium hydroxide solution dropwise into the precursor solution placed in magnetic stirring, adjust the pH value of the mixed solution to 10, form a transparent solution, continue magnetic stirring for 3h, and use the mixed solution obtained by stirring The glass rod was introduced into the reactor, and a white precipitate was obtained after a hydrothermal reaction at 200°C for 12 hours. The precipitate was repeatedly washed with ethanol and deionized water to remove excess ions, and dried at 90°C for 6 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com