Intensified biological treatment device and method for degradation-resistant organic nitrogen-rich chemical wastewater

A bioaugmentation and treatment device technology, applied in the direction of mechanical oscillation water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of difficult aerobic microbial decomposition, inability to achieve action, poor biodegradability of organic matter, etc. problem, achieve the effect of avoiding ultrasonic and electrical stimulation, efficient cleaning, and promoting activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

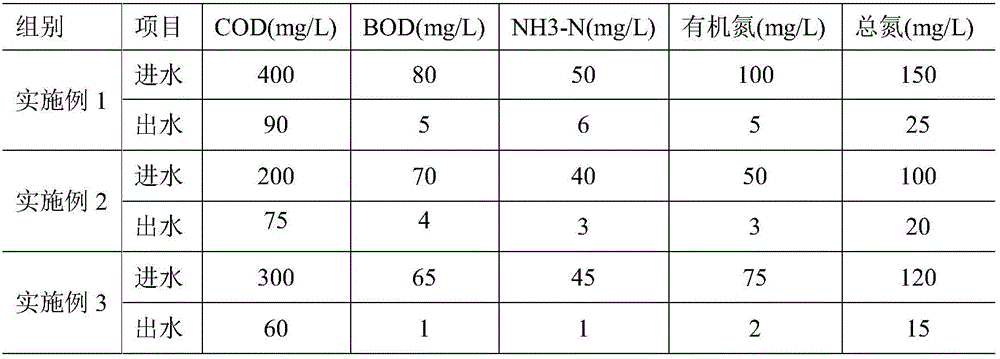

Embodiment 1

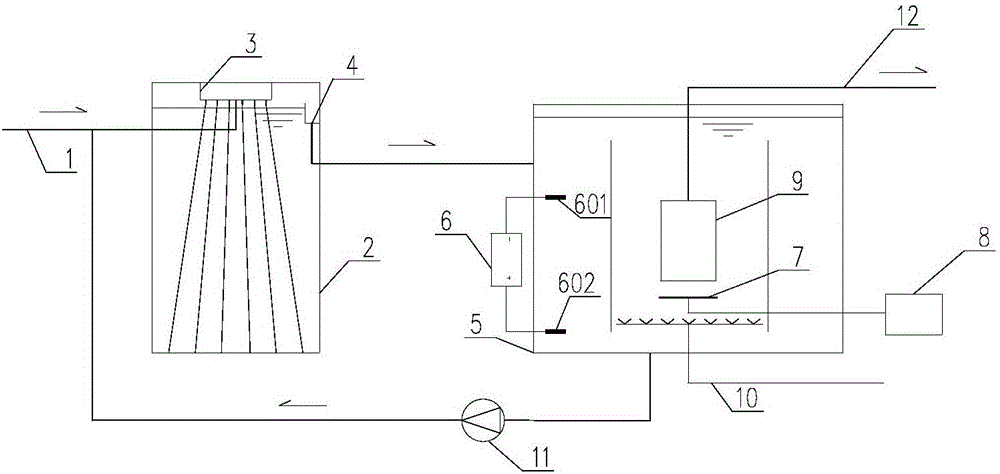

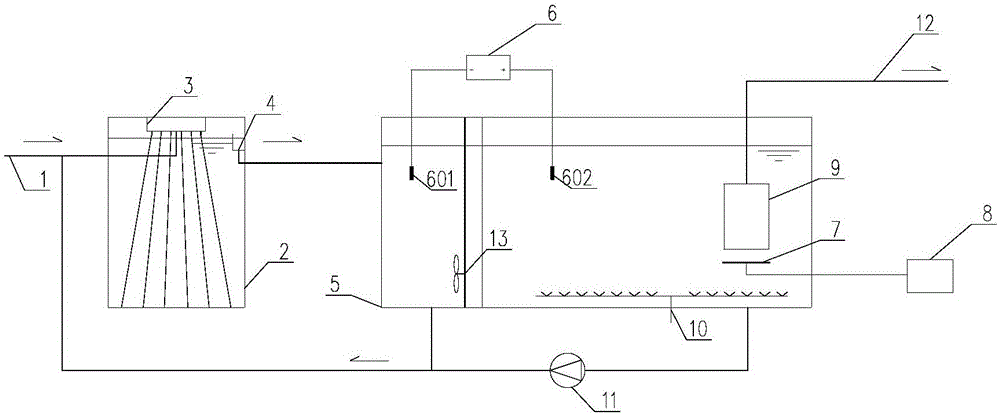

[0022] A bioaugmentation treatment device for refractory high organic nitrogen chemical wastewater, the bioaugmentation device includes a water inlet system 1 and an electrode 6; the water inlet system 1 is connected to a water distributor 3, and the water distributor 3 is installed in the hydrolysis acidification Above the reactor 2; the side wall above the hydrolytic acidification reactor 2 is provided with an outlet system 4 leading to the membrane bioreactor 5; an anoxic zone and an aerobic zone are provided in the membrane bioreactor 5; A transducer 7, a membrane module 9 and a biological layer 10 are arranged in the aerobic zone; the transducer 7 is connected to the ultrasonic generator 8; the membrane module 9 is connected to the water outlet 12; the bottom of the membrane bioreactor 5 is also A pipeline communicating with the water inlet system 1 is provided, and the pipeline is provided with a valve 11; the electrode 6 is located in the membrane bioreactor 5, its catho...

Embodiment 2

[0026] A bioaugmentation treatment device for refractory high organic nitrogen chemical wastewater, the bioaugmentation device includes a water inlet system 1 and an electrode 6; the water inlet system 1 is connected to a water distributor 3, and the water distributor 3 is installed in the hydrolysis acidification Above the reactor 2; the side wall above the hydrolytic acidification reactor 2 is provided with an outlet system 4 leading to the membrane bioreactor 5; an anoxic zone and an aerobic zone are provided in the membrane bioreactor 5; A transducer 7, a membrane module 9 and a biological layer 10 are arranged in the aerobic zone; the transducer 7 is connected to the ultrasonic generator 8; the membrane module 9 is connected to the water outlet 12; the bottom of the membrane bioreactor 5 is also A pipeline communicating with the water inlet system 1 is provided, and the pipeline is provided with a valve 11; the electrode 6 is located in the membrane bioreactor 5, its catho...

Embodiment 3

[0030] A bioaugmentation treatment device for refractory high organic nitrogen chemical wastewater, the bioaugmentation device includes a water inlet system 1 and an electrode 6; the water inlet system 1 is connected to a water distributor 3, and the water distributor 3 is installed in the hydrolysis acidification Above the reactor 2; the side wall above the hydrolytic acidification reactor 2 is provided with an outlet system 4 leading to the membrane bioreactor 5; an anoxic zone and an aerobic zone are provided in the membrane bioreactor 5; A transducer 7, a membrane module 9 and a biological layer 10 are arranged in the aerobic zone; the transducer 7 is connected to the ultrasonic generator 8; the membrane module 9 is connected to the water outlet 12; the bottom of the membrane bioreactor 5 is also A pipeline communicating with the water inlet system 1 is provided, and the pipeline is provided with a valve 11; the electrode 6 is located in the membrane bioreactor 5, its catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com