Zwitterion modified tetraphenylethylene, preparation method and application thereof

A technology of tetraphenylethylene and zwitterions, which is applied in the field of zwitterion-modified tetraphenylethylene and its preparation and application, can solve problems such as unclear interface modification layers, and achieve avoidance of adverse effects, excellent interface modification effects, and improved conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

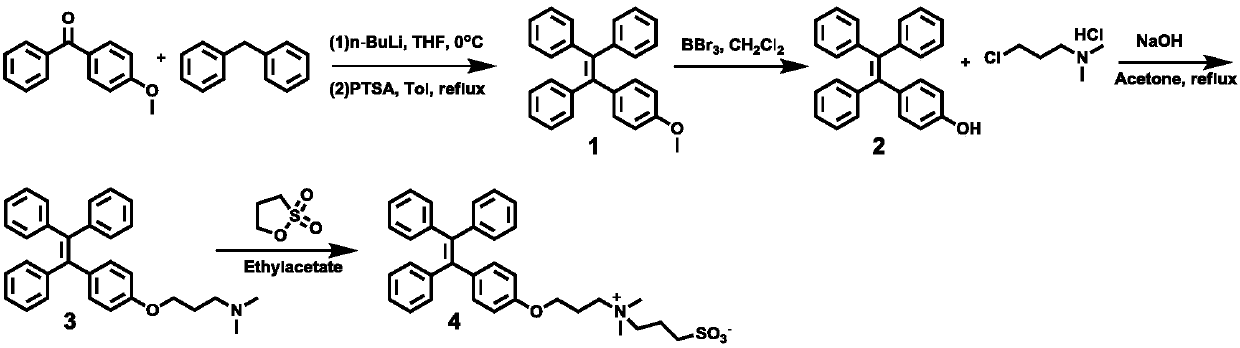

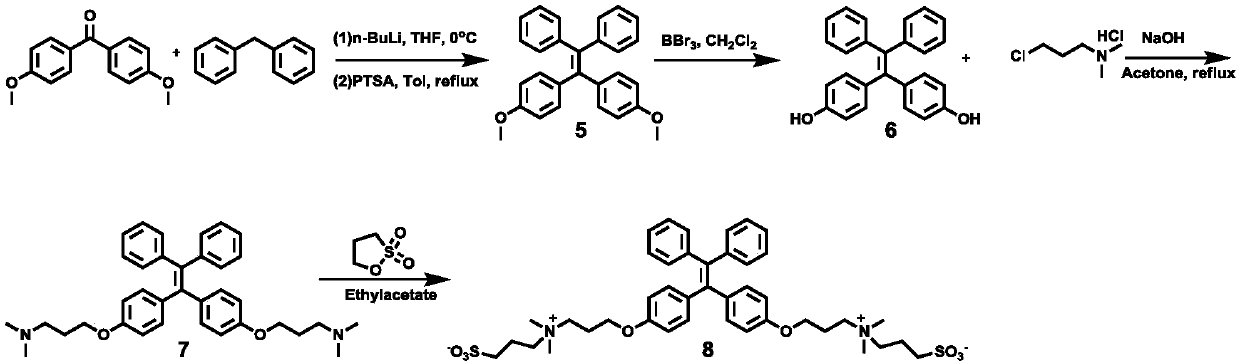

[0027] The synthesis of embodiment 1 compound 1-8

[0028] (1) Under a nitrogen atmosphere, add diphenylmethane (3.36g, 20mmol) and 80mL dry tetrahydrofuran into a Schlenk tube, add a 2.2M hexane solution of n-butyllithium (9.1mL, 20mmol) dropwise at 0°C, and Add 4-methoxybenzoylbenzene ( 3.40g, 16mmol), and continued to stir for 6 hours after naturally warming to room temperature. After completion of the reaction, add saturated aqueous ammonium chloride to quench the reaction, extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 After drying, the solvent was distilled off to obtain the intermediate crude product. The intermediate was dissolved in 80 mL of dry toluene in a 250 mL round bottom flask, a catalytic amount of p-toluenesulfonic acid monohydrate (570 mg, 3.0 mmol) was added, and refluxed for 12 hours. After the completion of the reaction, cool to room temperature and use 10wt% NaHCO 3 Wash the toluene solution with aqueous ...

Embodiment 2

[0037] Embodiment 2: Compound 4 and 8 are used as the device effect of the cathode interface modification material of polymer solar cell

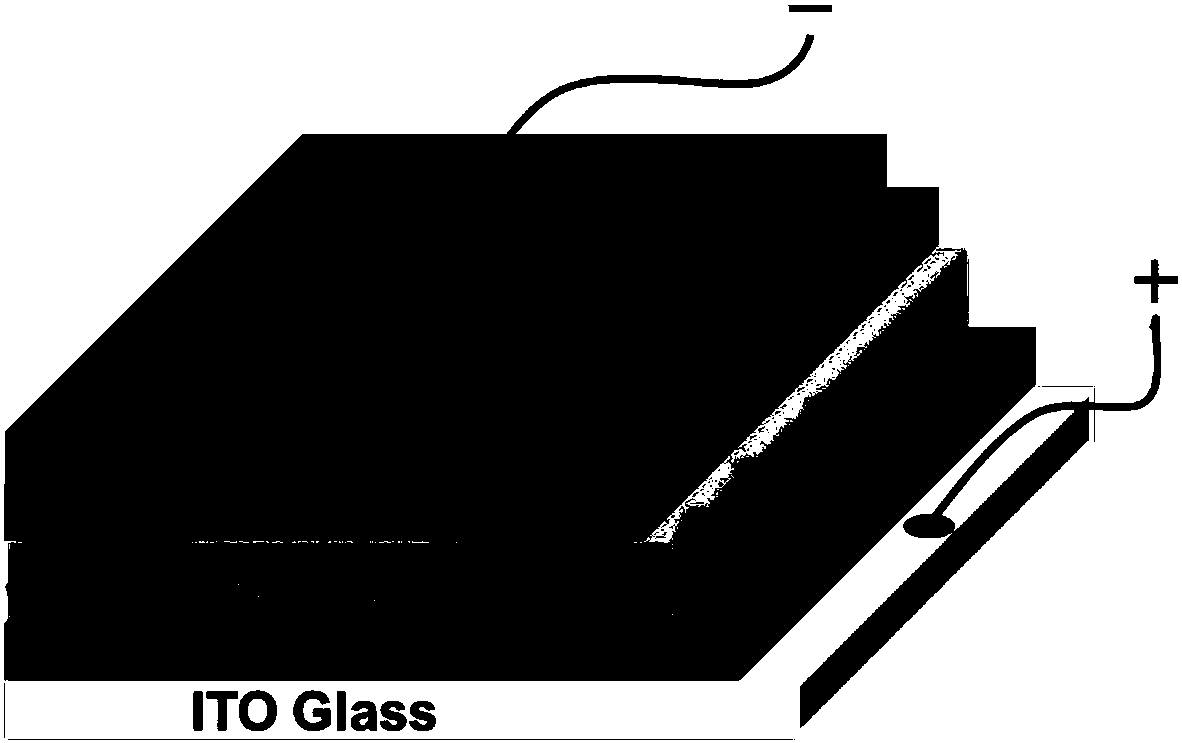

[0038] Aluminum is used as the cathode, compounds 4 and 8 are used as the interface modification layer of the aluminum electrode, and PTB7 is used as the active layer donor material, and the structural formula is Among them, R is PC 71 BM is used as the acceptor material of the active layer, and its structural formula is Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) (PEDOT:PSS) is used as the interface modification layer of the anode, and the structural formula is ITO glass was used as the anode. As a comparison, a device without a cathode interface modification layer and calcium as a cathode interface modification layer was also fabricated.

[0039] Compounds 4 and 8 of the present invention are used as cathode interface modification materials for bulk heterojunction polymer solar cells. With compound 4 cathode inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com