A kind of production process of modified dibasic lead phosphite and production system thereof

A kind of dibasic phosphorous acid, technology of production system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

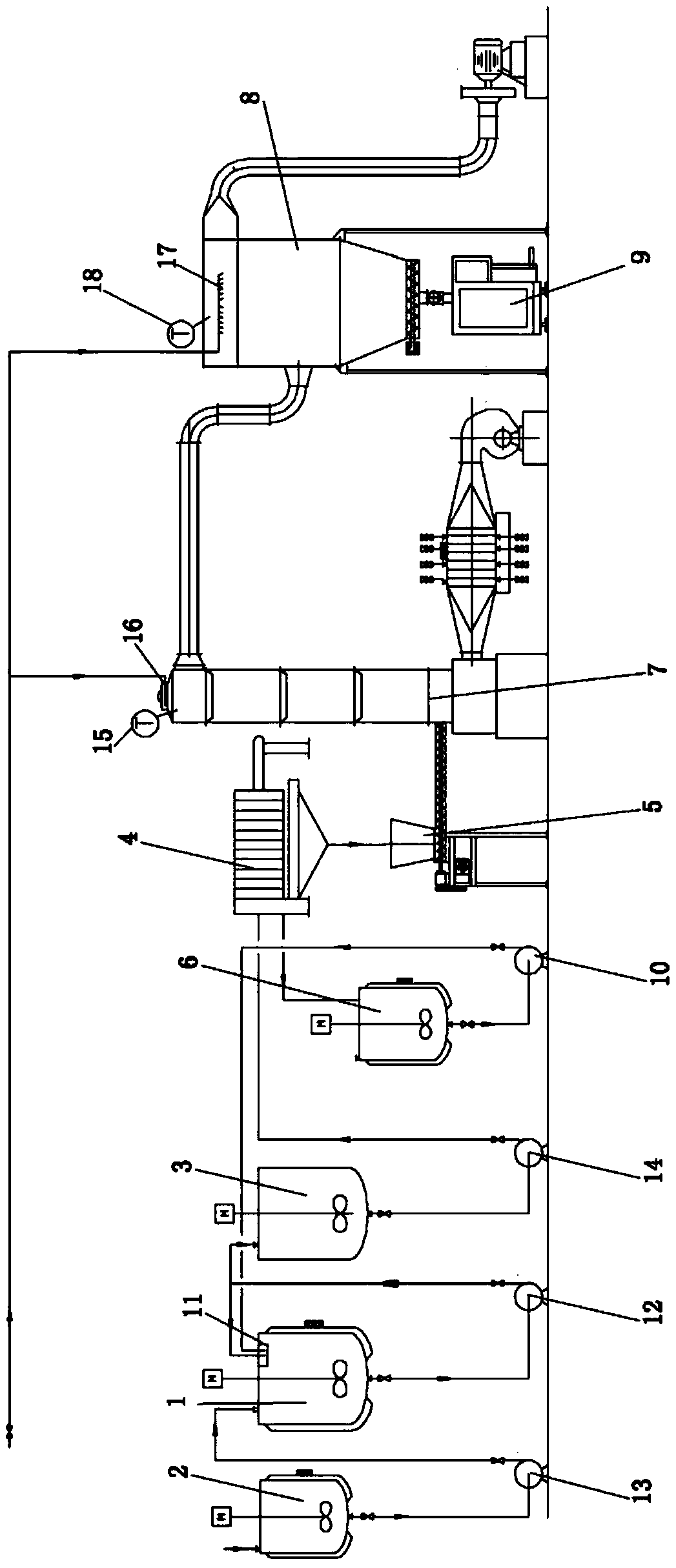

Image

Examples

Embodiment 1

[0036] A production process of modified dibasic lead phosphite, comprising the following steps:

[0037] In the first step, 89 parts of Huang Dan and 0.35 parts of acetic acid were mixed and stirred for more than 30 minutes, and then the temperature was raised to 60°C;

[0038] In the second step, add 1.2 parts of stearic acid and water to heat up to 80°C, then slowly add 0.3 parts of sodium hydroxide and react with stirring at 70-80°C for 40 minutes;

[0039] In the third step, slowly add 10 parts of phosphorous acid into the mixed material obtained in the first step, and then keep it in an environment of 60-70°C for 1 hour;

[0040] In the fourth step, the mixture obtained in the second step is added to the mixed material obtained in the third step, and then 0.08 parts of bisphenol A and 0.4 parts of magnesium hydroxide are added and stirred for 10 minutes;

[0041] In the fifth step, the mixed material obtained in the fourth step is press-filtered, dried, dedusted and pack...

Embodiment 2

[0043] A production process of modified dibasic lead phosphite, comprising the following steps:

[0044] In the first step, 85 parts of Huang Dan and 0.5 parts of acetic acid were mixed and stirred for more than 30 minutes, and then the temperature was raised to 60°C;

[0045] In the second step, add 1.4 parts of stearic acid and water to heat up to 80°C, then slowly add 0.2 parts of ammonia water and 0.02 parts of stearic acid polyoxyethylene ether at 70-80°C and stir for 40 minutes;

[0046] In the third step, slowly add 12 parts of phosphorous acid into the mixed material obtained in the first step, and then keep it in an environment of 60-70°C for 1 hour;

[0047] In the fourth step, add the mixture obtained in the second step to the mixed material obtained in the third step, then add 1 part of 2-hydroxy-4-n-octyloxybenzophenone and 0.2 parts of magnesium hydroxide and stir for 10 minutes ;

[0048] In the fifth step, the mixed material obtained in the fourth step is pre...

Embodiment 3

[0050] A production process of modified dibasic lead phosphite, comprising the following steps:

[0051] In the first step, 87 parts of Huang Dan and 0.2 parts of acetic acid were mixed and stirred for more than 30 minutes, and then the temperature was raised to 60°C;

[0052] In the second step, add 1.6 parts of stearic acid and water to heat up to 80°C, then slowly add 0.1-0.3 parts of sodium hydroxide and react with stirring at 70-80°C for 40 minutes;

[0053] In the third step, slowly add 1 part of cyanuric acid and 9 parts of phosphorous acid into the mixed material obtained in the first step, and then keep it in an environment of 60-70°C for 1 hour; first add 1 part by mass of cyanuric acid The mixed material obtained in the first step was stirred and reacted for 15 minutes, and then 9 parts of phosphorous acid was slowly added.

[0054] In the fourth step, the mixture obtained in the second step is added to the mixed material obtained in the third step, and then 0.08 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com