A kind of environment-friendly vacuum quenching oil and preparation method thereof

A vacuum quenching oil, environmental protection technology, applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of reducing the use effect of vacuum quenching oil, high moisture content requirements, production cost impact, etc., to achieve high brightness and Good thermal stability, brightness and thermal stability, and good cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

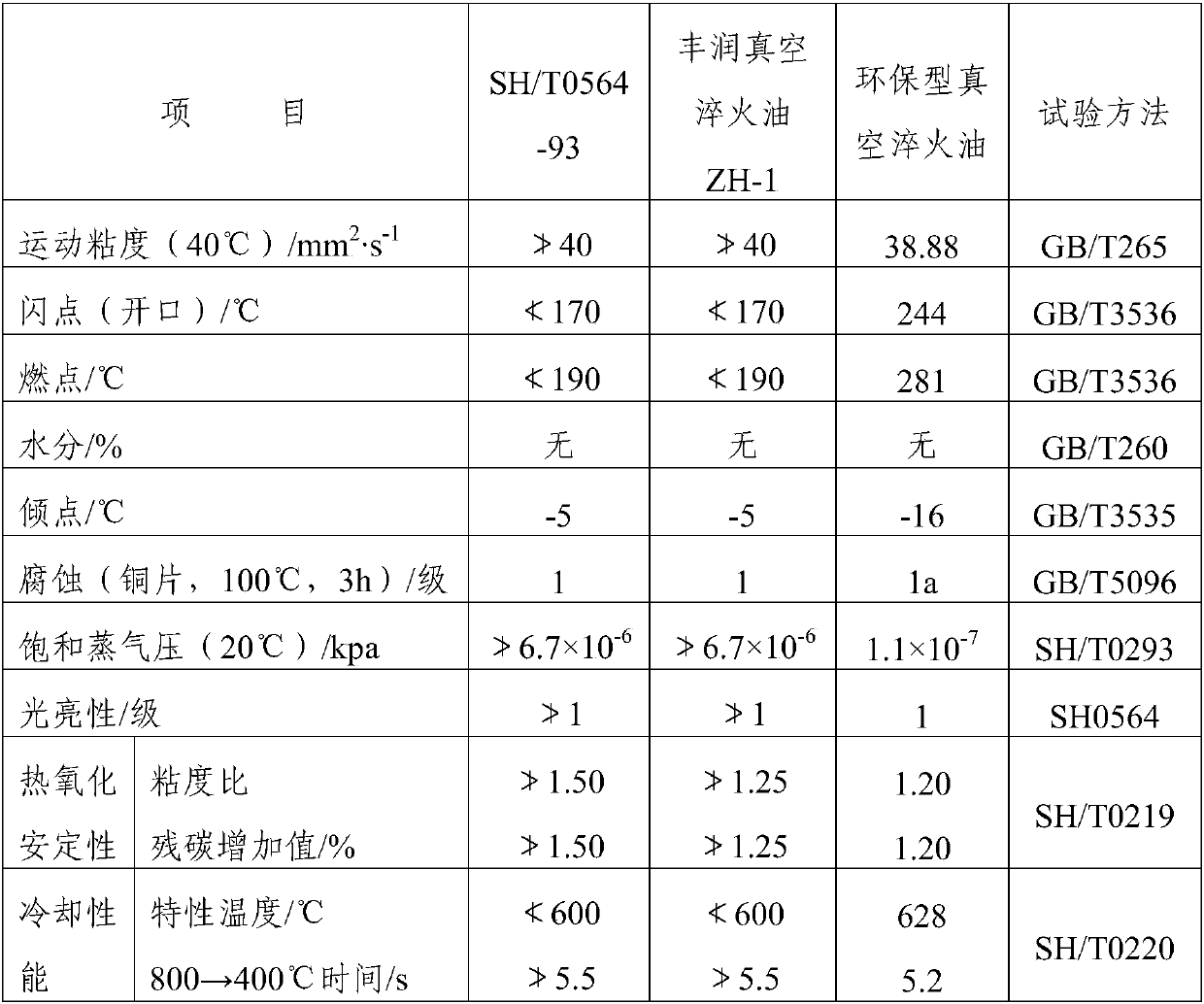

[0036] An environment-friendly vacuum quenching oil, made of the following raw materials in parts by weight: 83.1 parts of Korean SsangYong 200N Type III base oil, 2 parts of polyisobutylene succinimide, 2 parts of sodium petroleum sulfonate, INEOS S-52 10 parts, 1 part of molybdenum dialkyldithiocarbamate sulfide, 0.5 parts of 4,4'-methylenebis(2,6-di-tert-butylphenol), 2,6-di-tert-butyl-p-cresol 0.3 parts, 0.1 parts of polydimethylsilicone oil, and 1 part of dodecenylsuccinic acid.

[0037] A preparation method of environment-friendly vacuum quenching oil, comprising the steps of:

[0038] (1) Pump Korean Ssangyong 200N Type III base oil into the vacuum air conditioner and kettle, turn on the stirring, turn on the vacuum system, heat the oil temperature to 75°C, keep the vacuum degree of the system at -0.096MPa, and stir for 30 minutes;

[0039] (2) Close the vacuum system, use the vacuum of the vacuum air conditioner and the kettle to mix 2 parts of polyisobutylene succini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com