Tungsten-rhenium-molybdenum alloy rotary anode target material for X-ray tube and preparation method thereof

A technology of X-ray tube and rotating anode, which is applied in the direction of X-ray tube electrodes, X-ray tubes, X-ray tube parts, etc., can solve the problems of low sintering density, many forging passes, high cost, etc., and achieve the content of impurity elements Low, increase the connection strength, the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

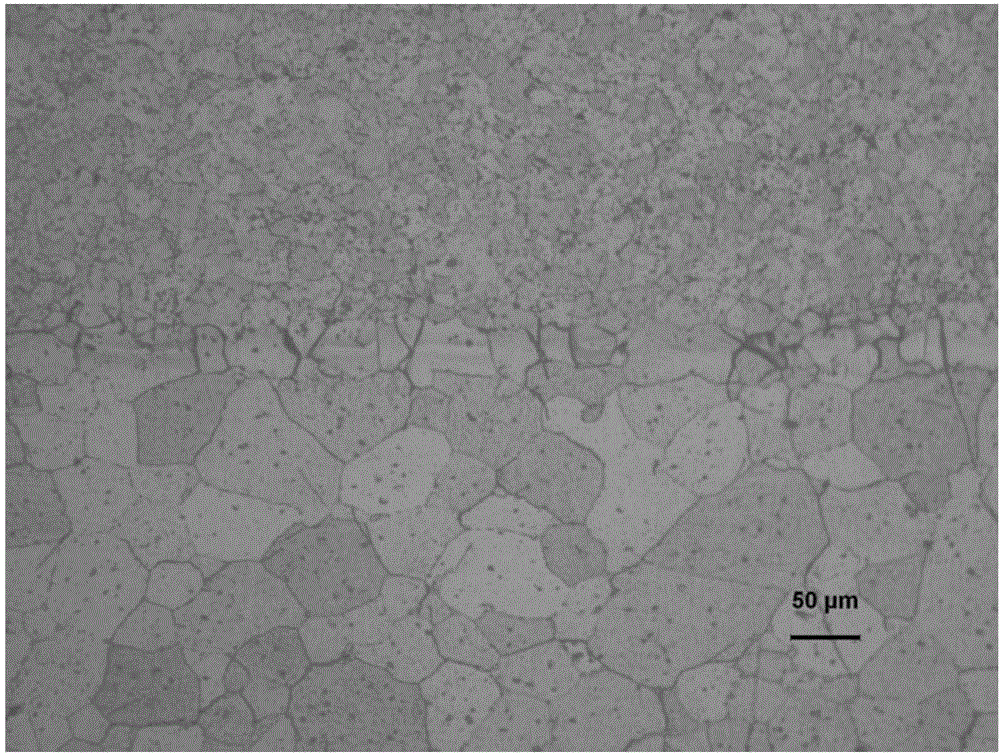

Image

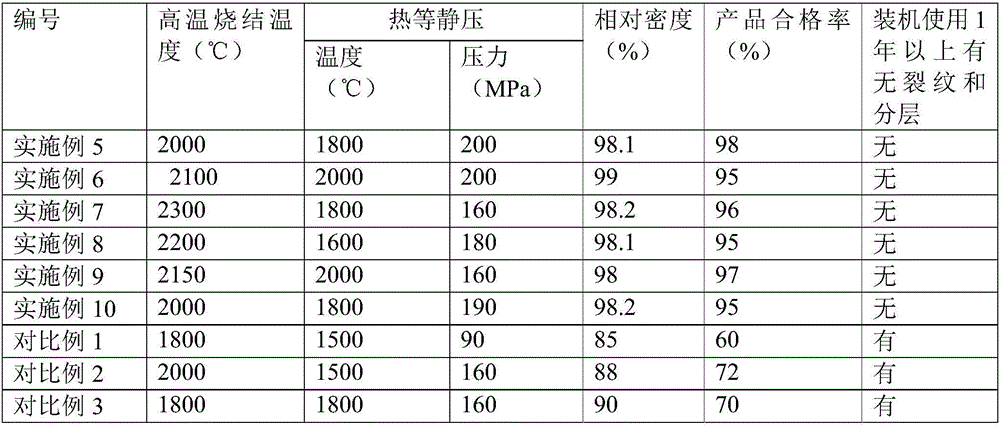

Examples

Embodiment 1

[0037] (1) Preparation of tungsten-rhenium pre-alloyed powder: Weigh respectively 238g of tungsten powder with a Fibonacci particle size of 3.0 μm and a purity of 99.95% and 18g of ammonium rhenate powder with a purity of 99.99% after grinding and passing through a 200 mesh sieve, and then mix the rhenium Add the ammonium acid powder into a mixer equipped with tungsten powder for mixing, the speed is 20r / min, and the mixing time is 1 hour; after mixing evenly, carry out the first hydrogen reduction treatment, that is, react at 420°C for 0.5 hours; then carry out The second hydrogen reduction treatment was to react at 850° C. for 0.5 hours. After the reduction reaction is completed, 250g of rhenium-tungsten pre-alloyed powder is obtained, that is, 5Re-W powder (the mass fraction of rhenium in the tungsten-rhenium pre-alloyed powder is 5%).

[0038] (2) Preparation of molybdenum alloy powder: Weigh 740g of molybdenum powder with a Fischer particle size of 4.0 μm and a purity of ...

Embodiment 2

[0047](1) Preparation of tungsten-rhenium pre-alloyed powder: take respectively 270 g of tungsten powder with a Fibonacci particle size of 4.0 μm and a purity of 99.95% and 43.5 g of ammonium rhenate powder with a purity of 99.99% after grinding and passing through a 200 mesh sieve, and then Add the ammonium rhenate powder into a mixer equipped with tungsten powder for mixing, the rotation speed is 15r / min, and the mixing time is 1 hour; after mixing evenly, carry out the first hydrogen reduction treatment, that is, react at 350°C for 1 hour, and then Carry out the second hydrogen reduction treatment, that is, react at 900°C for 0.5 hours. After the reduction reaction is completed, 300g of rhenium-tungsten pre-alloyed powder is obtained, that is, 10Re-W powder (the mass fraction of rhenium in the tungsten-rhenium pre-alloyed powder is 10%).

[0048] (2) Preparation of molybdenum alloy powder: take by weighing 885g of molybdenum powder with a Fibonacci particle size of 2.0 μm a...

Embodiment 3

[0057] (1) Preparation of tungsten-rhenium pre-alloyed powder: take respectively 247.5g of tungsten powder with a Fibonacci particle size of 2.0 μm and a purity of 99.95% and 3.6g of ammonium rhenate powder with a purity of 99.99% after grinding and grinding. Add the ammonium rhenate powder into a mixer equipped with tungsten powder for mixing, the rotation speed is 15r / min, and the mixing time is 2 hours; after mixing evenly, carry out the first hydrogen reduction treatment, that is, react at 500°C for 0.5 hours; Then carry out the second hydrogen reduction treatment, that is, react at 800° C. for 1 hour. After the reduction reaction is completed, 250g of rhenium-tungsten pre-alloyed powder is obtained, that is, 1Re-W powder (the mass fraction of rhenium in the tungsten-rhenium pre-alloyed powder is 1%).

[0058] (2) Preparation of molybdenum alloy powder: Weigh 695.5g of molybdenum powder with a Fischer particle size of 5.0 μm and a purity of 99.95%; TiH with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com