Preparation of porous tin oxide-CNTs photocatalytic material based on oxidation and reduction of Cu+/Cu

A photocatalytic material, tin oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, alkali metal oxide/hydroxide, etc., can solve the problem of low catalytic activity, Achieve the effect of improving catalytic ability, excellent ability, and improving the ability of catalytic degradation of organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

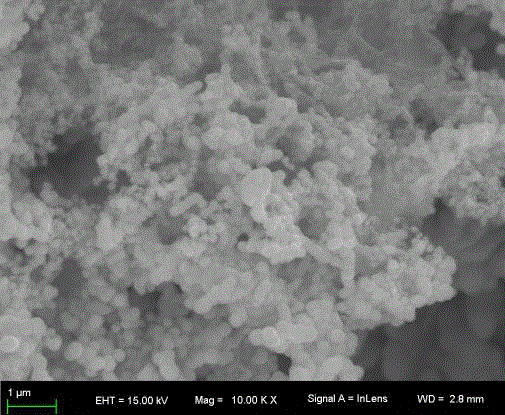

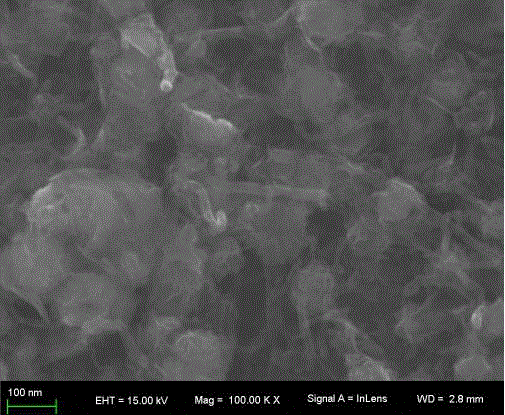

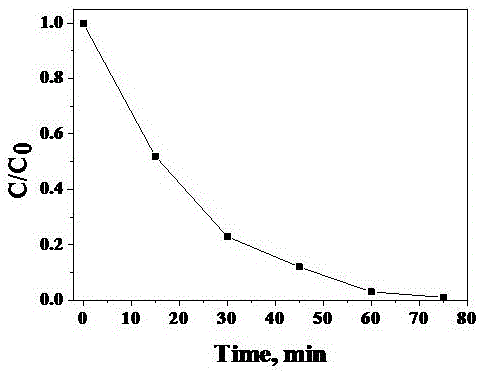

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation manner 1: Cu-based + The preparation of porous tin oxide-CNTs photocatalytic material by oxidation-reduction of Cu / Cu is carried out in the following steps:

[0015] 1. Based on Cu + / Cu redox to prepare porous tin oxide-CNTs photocatalytic material, which is characterized by Cu + The preparation of porous tin oxide-CNTs photocatalytic material by oxidation-reduction of Cu / Cu is carried out in the following steps:

[0016] (1) Electrodeposition of imitation gold bronze-CNTs on the surface of conductive glass: a. Dissolve 8~80 mL of hydrochloric acid in 700 mL of deionized water, slowly add 5~15 g of hydroquinone, and then add 5~12 g Potassium hydrogen tartrate, stir until all is dissolved, add 1~6 g of stannous chloride and aging for 24h to prepare solution A; b. Add 35~120 g of thiourea to solution A, heat and stir until completely dissolved, then add 5 ~35g cuprous oxide, stirred at 50~80 ℃ for 2 hours, then filtered under normal pressure while hot,...

specific Embodiment approach 2

[0020] Specific embodiment two: This embodiment is different from the specific embodiment one in that the processing time of the ultrasonic cell pulverizer described in step (1) c is 12-50 h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the electrodeposition time described in e of step (1) is 15 to 90 min. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com