Preparation method of ultralong silver nanowires

A silver nanowire, ultra-long technology, applied in the nano field, can solve the problems of increasing the difficulty of production control, increasing production costs, technical difficulties, etc., and achieving the effects of excellent optoelectronic properties, easy operation and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

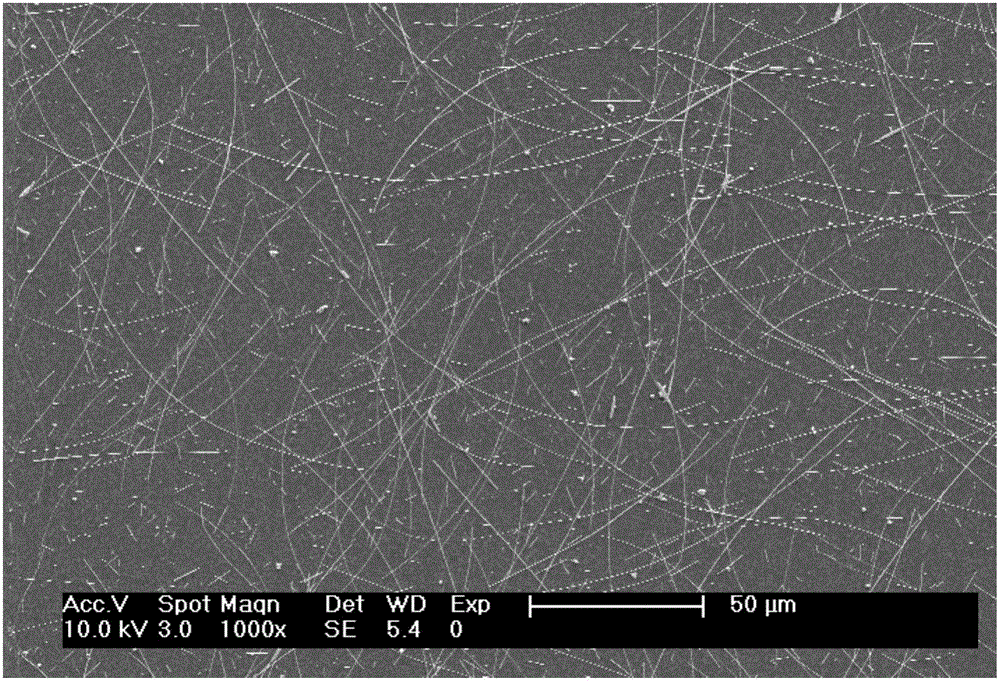

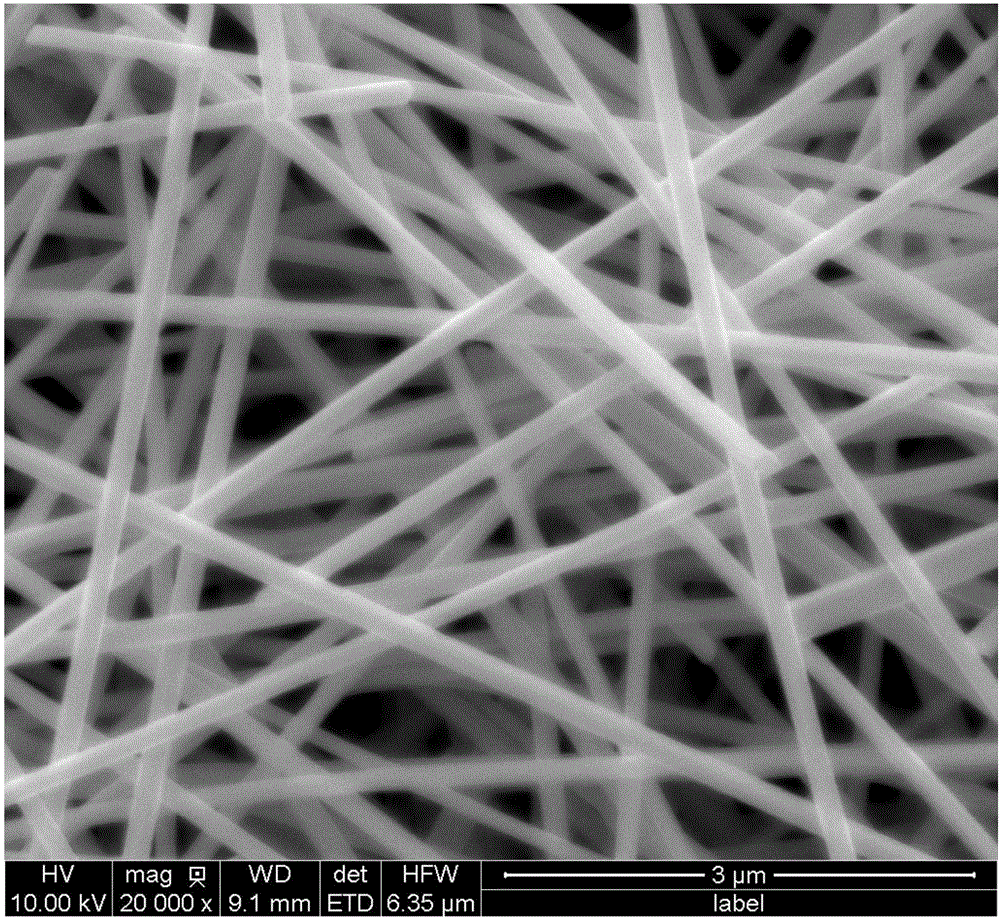

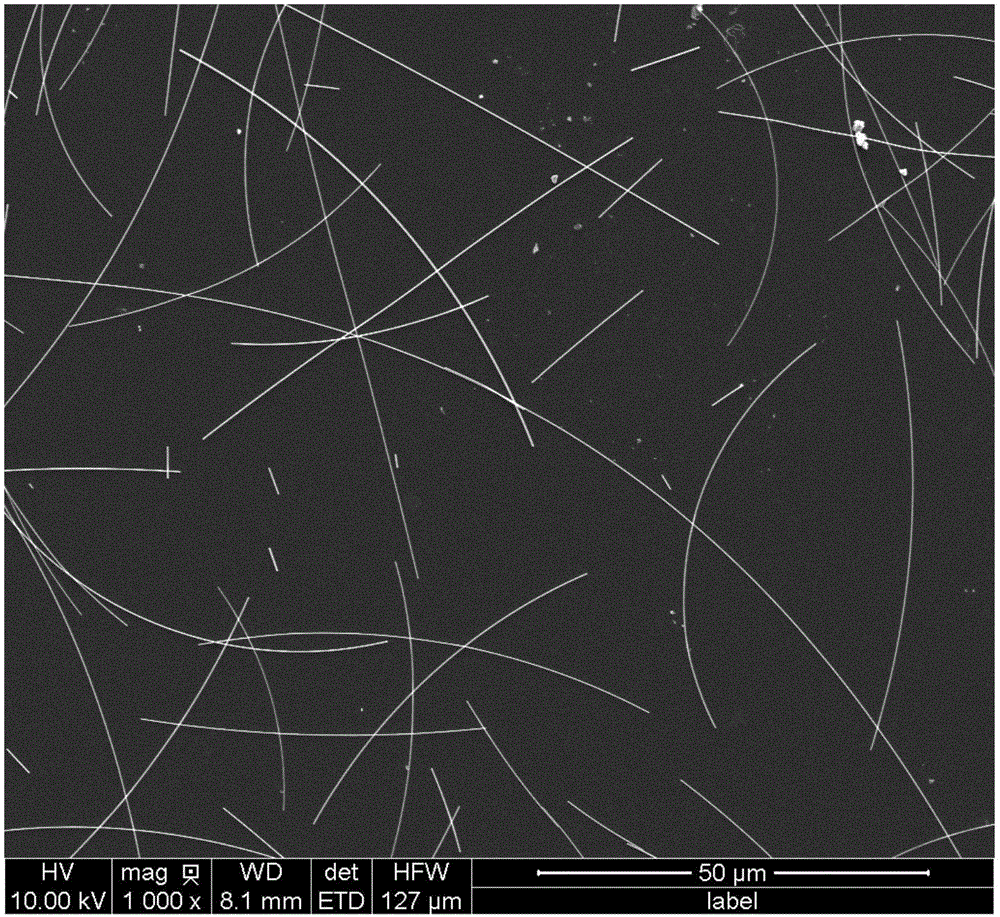

Image

Examples

Embodiment 1

[0023] The preparation method of the ultralong silver nanowire of embodiment 1, comprises the following steps:

[0024] (1) preparation molar concentration is the ethylene glycol solution of the dodecyltrimethylammonium chloride of 600 μ mol / L, stand-by;

[0025] (2) Prepare FeCl with a molar concentration of 600 μmol / L 3 Ethylene glycol solution, stand-by;

[0026] (3) Add 0.3 g of polyvinylpyrrolidone with an average molecular weight of 360,000 and 58,000 to 100 mL of ethylene glycol, stir well until completely dissolved, and prepare a mixed polyvinylpyrrolidone glycol solution with a total mass concentration of 0.006 g / mL ,stand-by;

[0027] (4) 0.7g silver nitrate is added in the mixed polyvinylpyrrolidone ethylene glycol solution of preparation, obtain mixed solution after fully stirring;

[0028] (5) The prepared 1mL of dodecyltrimethylammonium chloride ethylene glycol solution and 9mL of FeCl 3 Add the ethylene glycol solution in the mixed solution that obtains in s...

Embodiment 2

[0030] The preparation method of the ultralong silver nanowire of embodiment 2, comprises the following steps:

[0031] (1) preparation molar concentration is the ethylene glycol solution of the dodecyltrimethylammonium chloride of 600 μ mol / L, stand-by;

[0032] (2) Prepare FeCl with a molar concentration of 600 μmol / L 3 Ethylene glycol solution, stand-by;

[0033] (3) Add 0.3 g of polyvinylpyrrolidone with an average molecular weight of 360,000 and 58,000 to 100 mL of ethylene glycol, stir well until completely dissolved, and prepare a mixed polyvinylpyrrolidone glycol solution with a total mass concentration of 0.006 g / mL ,stand-by;

[0034] (4) 0.7g silver nitrate is added in the mixed polyvinylpyrrolidone ethylene glycol solution of preparation, obtain mixed solution after fully stirring;

[0035] (5) The prepared 2mL of dodecyltrimethylammonium chloride ethylene glycol solution and 8mL of FeCl 3 Add the ethylene glycol solution in the mixed solution that obtains in s...

Embodiment 3

[0037] The preparation method of the ultralong silver nanowire of embodiment 3, comprises the following steps:

[0038] (1) preparation molar concentration is the ethylene glycol solution of the dodecyltrimethylammonium chloride of 600 μ mol / L, stand-by;

[0039] (2) Prepare FeCl with a molar concentration of 600 μmol / L 3 Ethylene glycol solution, stand-by;

[0040] (3) Add 0.4 g of polyvinylpyrrolidone with an average molecular weight of 360,000 and 58,000 to 100 mL of ethylene glycol, stir well until completely dissolved, and prepare a mixed polyvinylpyrrolidone glycol solution with a total mass concentration of 0.008 g / mL ,stand-by;

[0041] (4) 0.7g silver nitrate is added in the mixed polyvinylpyrrolidone ethylene glycol solution of preparation, obtain mixed solution after fully stirring;

[0042] (5) The prepared 3mL of dodecyltrimethylammonium chloride ethylene glycol solution and 7mL of FeCl 3 Add the ethylene glycol solution in the mixed solution obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com