Acrylic resin having excellent compatibility with environment-friendly plasticizers

A technology of acrylic resin and plasticizer, which is applied in the field of acrylic resin, can solve problems such as poor compatibility, and achieve the effect of simple preparation process, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

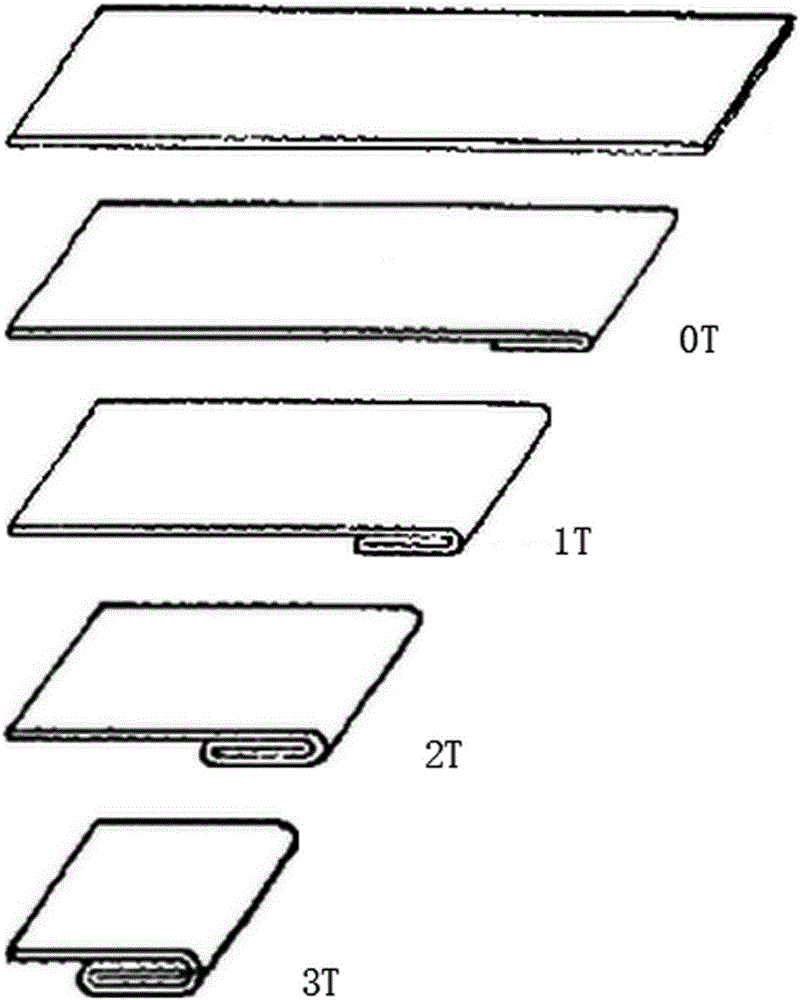

Image

Examples

Embodiment

[0026] 0.1 mass parts dispersant (polyvinyl alcohol) and 64.4 mass parts deionized water were stirred and mixed uniformly at room temperature, then the temperature was raised to 65°C; 34.67 mass parts monomers of the composition shown in Table 1, 0.55 mass parts initiator ( Azobisisobutyronitrile), 0.07 parts by mass of surfactant (sodium lauryl sulfate), 0.21 parts by mass of molecular weight regulator (n-dodecyl mercaptan), insulated and stirred for 8 hours, and the stirring speed was 450rpm. That is, the acrylic resin of the present invention is obtained.

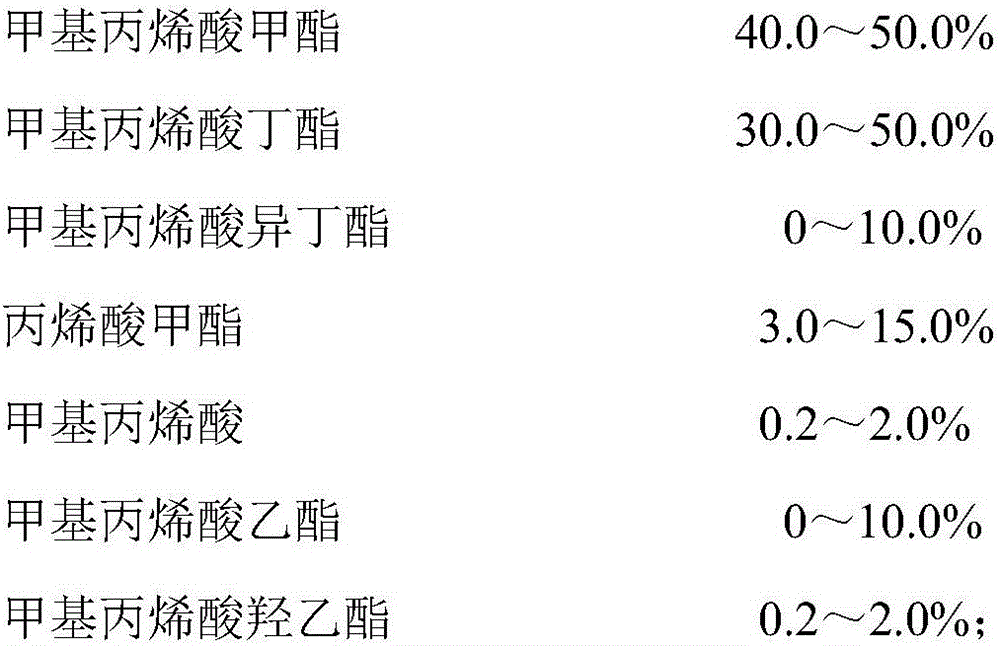

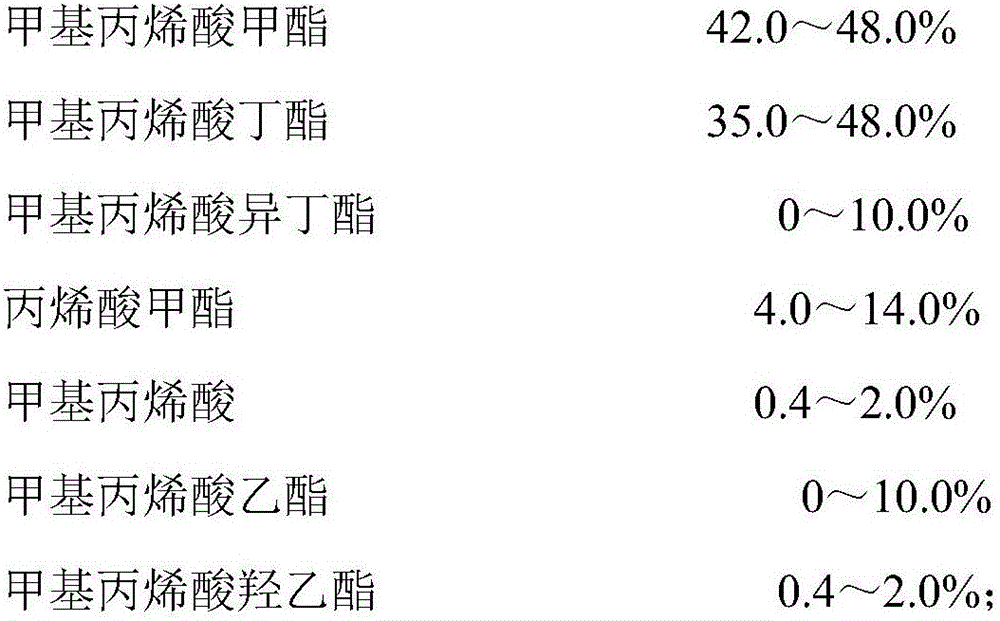

[0027] Table 1 monomer composition formula (wt%, mass percent)

[0028] Numbering MMA BMA IBMA MA MAA EMA HEMA 1 42.0 42.0 0 12.6 1.7 0 1.7 2 47.2 47.2 0 4.8 0.4 0 0.4 3 45.9 36.7 0 13.8 1.8 0 1.8 4 45.9 36.7 9.2 4.6 1.8 0 1.8 5 45.9 36.7 0 4.6 1.8 9.2 1.8 6 44.6 35.7 4.5 8.9 0.9 4.5 0.9

[0029] Note: MMA is the abbreviation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com