Water soluble nano-polysilicon/polymer gel oil-displacing-agent and preparation method thereof

An oil-displacing agent and polymer technology, applied in the field of water-soluble nano-polysilicon/polymer gel oil-displacing agent and its preparation, can solve the problem of threats to economic security and energy security, affecting oil-displacing performance, and poor shear resistance. and other problems, to achieve the effect of high modulus, increased swept volume, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of water-soluble nano polysilicon / polymer gel oil displacement agent, it specifically comprises the following steps:

[0030] 1) Dissolve 4 parts of 2-acrylamide-2-methylpropanesulfonic acid in 50 parts of deionized water, add dropwise sodium hydroxide solution to neutralize to pH 8 to obtain solution A;

[0031] 2) Dissolve 5 parts of acrylamide and 0.3 part of sodium dodecylsulfonate in 45 parts of deionized water to obtain solution B;

[0032] 3) After mixing solution A and solution B, add 0.05 parts of reactive nano-polysilicon RNS-D and mix well, then transfer to a four-necked flask; 2 Stir for 30 minutes to allow the 2 Then add 0.15 parts of ammonium persulfate into the four-neck flask, raise the temperature to 85 °C and keep it warm for 8 hours to obtain a viscous gel oil displacement agent.

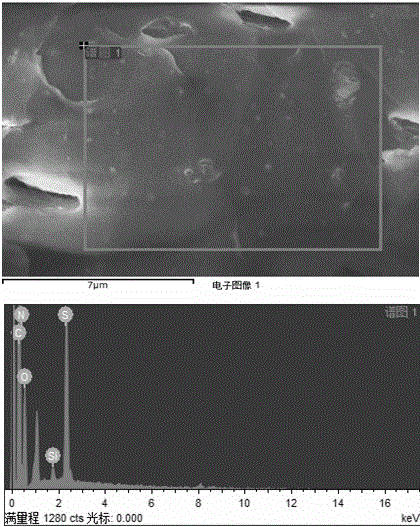

[0033] figure 1 In order to prepare the optical photograph of the obtained water-soluble nano polysilicon / polymer gel oil displacement agent...

Embodiment 2

[0044] A kind of preparation method of water-soluble nano polysilicon / polymer gel oil displacement agent, it specifically comprises the following steps:

[0045] 1) Dissolve 2 parts of 2-acrylamide-2-methylpropanesulfonic acid in 40 parts of deionized water, add dropwise sodium hydroxide solution to neutralize to pH 6 to obtain solution A;

[0046] 2) Dissolve 5 parts of acrylamide and 0.2 parts of sodium dodecylsulfonate in 30 parts of deionized water to obtain solution B;

[0047] 3) After mixing solution A and solution B, add 0.01 part of reactive nano-polysilicon RNS-D and mix evenly, then transfer it into a four-neck flask; 2 Stir for 30 minutes to allow the 2 Then add 0.05 parts of ammonium persulfate into the four-neck flask, raise the temperature to 70 °C and keep it warm for 8 hours to obtain a viscous gel oil displacement agent.

Embodiment 3

[0049] A kind of preparation method of water-soluble nano polysilicon / polymer gel oil displacement agent, it specifically comprises the following steps:

[0050] 1) Dissolve 2 parts of 2-acrylamide-2-methylpropanesulfonic acid in 45 parts of deionized water, add dropwise sodium hydroxide solution to neutralize to pH 9 to obtain solution A;

[0051] 2) Dissolve 6 parts of acrylamide and 0.2 parts of sodium dodecylsulfonate in 40 parts of deionized water to obtain solution B;

[0052] 3) After mixing solution A and solution B, add 0.15 parts of reactive nano-polysilicon RNS-D and mix well, then transfer to a four-neck flask; 2 Stir for 30 minutes to allow the 2 Then add 0.09 parts of ammonium persulfate into the four-neck flask, raise the temperature to 75 °C and keep it warm for 10 hours to obtain a viscous gel oil displacement agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com