Method for extracting carotenoid monomer pigment mainly containing zeaxanthin from wolfberries

A technology of zeaxanthin and carotene, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of high production cost, difficulty in large-scale preparation, complicated preparation process, etc., and achieve low cost and smooth preparation process The effect of being simple and easy to implement and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for extracting zeaxanthin-based carotenoid monomer pigments from wolfberry, specifically comprising the following steps:

[0065] A. Crushing

[0066] Crush and sieve wolfberry, the particle size of wolfberry powder is 180~300μm;

[0067] B. Extraction preparation

[0068] Add KOH powder to the ethanol solution with a mass concentration of 95%, stir and dissolve, and the KOH mass concentration is 2g / ml to make a mixed extract;

[0069] C. Pigment extraction

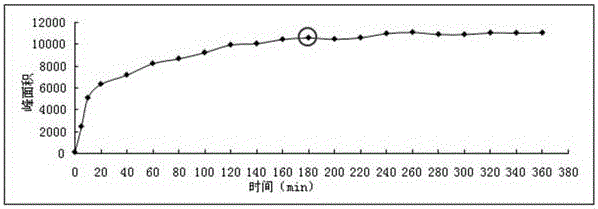

[0070] Lycium barbarum powder is added to the mixed extract solution, the wolfberry powder and the mixed extract solution are mixed and added at a mass ratio of 1:5, the temperature is raised to 40°C for an extraction reaction for 1 hour, the extraction reaction is combined with stirring and ultrasonic treatment, the stirring speed is 150rpm, the ultrasonic power is 150w, and the frequency 30MHz, filter impurities to obtain wolfberry pigment extract;

[0071] D. Separation

[0072] Add mass concentrat...

Embodiment 2

[0080] A method for extracting zeaxanthin-based carotenoid monomer pigments from wolfberry, specifically comprising the following steps:

[0081] A. Crushing

[0082] Crush and sieve wolfberry, the particle size of wolfberry powder is 300 μm;

[0083] B. Extraction preparation

[0084] Add KOH powder to the ethanol solution with a mass concentration of 100%, stir and dissolve, and the KOH mass concentration is 8g / ml to make a mixed extract;

[0085] C. Pigment extraction

[0086] Lycium barbarum powder is added to the mixed extract solution. The wolfberry powder and the mixed extract solution are mixed and added at a mass ratio of 1: 15. The temperature is raised to 60°C for extraction reaction for 5 hours. The extraction reaction is combined with stirring and ultrasonic treatment. The stirring speed is 200rpm, the ultrasonic power is 350w, and the frequency 80MHz, filter impurities to obtain wolfberry pigment extract;

[0087] D. Separation

[0088] Add HCl solution with a...

Embodiment 3

[0096] A method for extracting zeaxanthin-based carotenoid monomer pigments from wolfberry, specifically comprising the following steps:

[0097] A. Crushing

[0098] The wolfberry is crushed and sieved, the particle size of the wolfberry powder is 250 μm;

[0099] B. Extraction preparation

[0100] Add KOH powder to the ethanol solution with a mass concentration of 100%, stir and dissolve, and the KOH mass concentration is 6g / ml to make a mixed extract;

[0101] C. Pigment extraction

[0102] Lycium barbarum powder is added to the mixed extract solution, the wolfberry powder and the mixed extract solution are mixed and added at a mass ratio of 1:5, the temperature is raised to 55°C, and the extraction reaction is carried out for 3 hours. The extraction reaction is combined with stirring and ultrasonic treatment. The stirring speed is 180rpm, and the ultrasonic power is 200w. Frequency 50MHz, filter impurities to obtain wolfberry pigment extract;

[0103] D. Separation

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com