Preparation method for artificial cartilage

A cartilage and artificial technology, applied in the field of artificial cartilage preparation, can solve the problems of poor microscopic pore structure, poor affinity of artificial cartilage materials, etc., to meet the requirements of cartilage cell adhesion, good biomechanical properties, and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

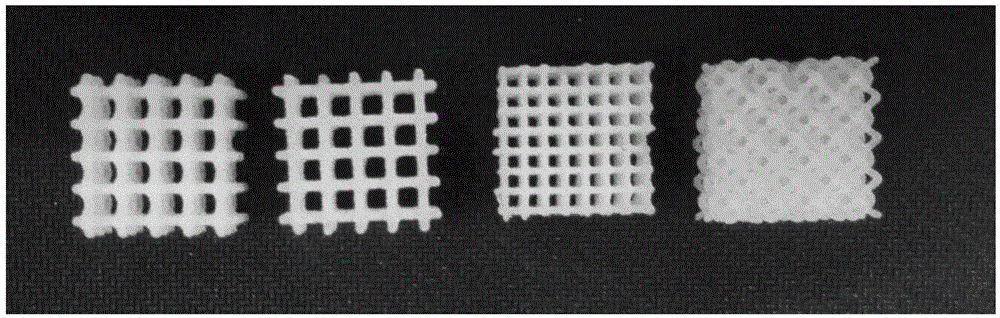

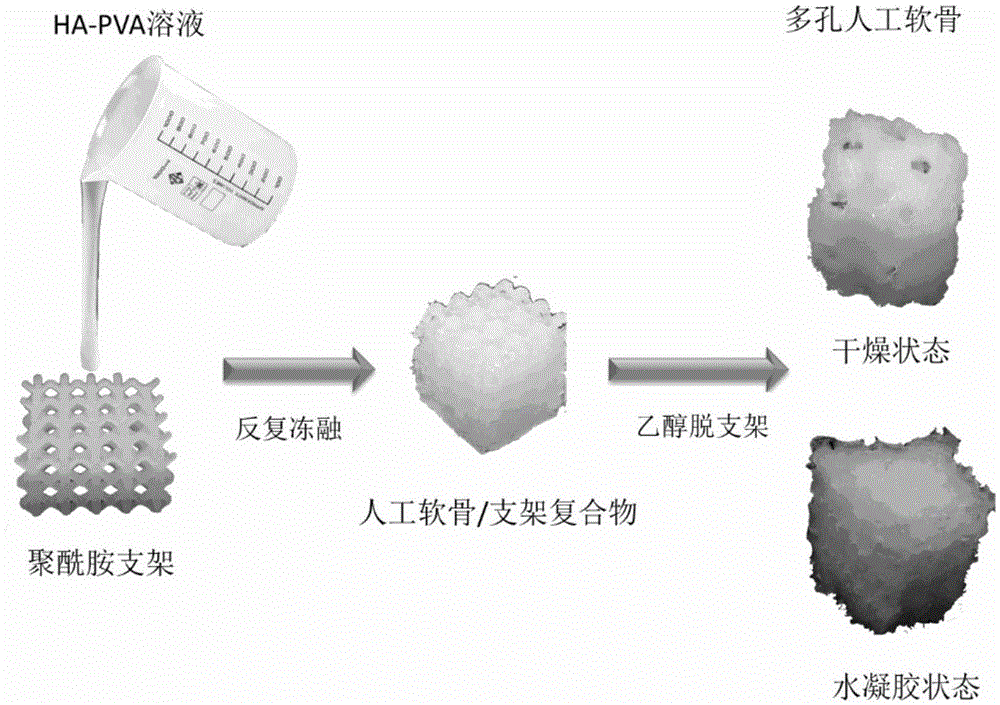

[0032] 1) Using polyamide polymer materials as raw materials, a pore scaffold with a three-dimensional network structure was first printed by SLS selective laser sintering technology (such as figure 1 described), the pore skeleton structure is stable, and the shape can be designed according to needs.

[0033] 2) Adding nano-hydroxyapatite powder into the PVA solution, stirring and mixing continuously, to make HA-PVA composite liquid, controlling the HA content to 5wt%, and the PVA content to 15wt%.

[0034] 3) Invert the prepared HA-PVA composite solution in the pore support, and inject the compound into the mold after the HA-PVA composite solution completely penetrates into the pore support; place the mold in a ‐20°C refrigerator for 10 hours , and then thawed at room temperature for 2 hours, this is a freeze-thaw cycle, repeated 5 times in this way, increasing the intermolecular cross-linking, and obtaining the artificial cartilage / scaffold complex;

[0035] 4) Soak the art...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com