Butadiene styrene rubber/white carbon black/lignocellulose/montmorillonite rubber composite material and preparation method thereof

A technology of lignocellulose and styrene-butadiene rubber, applied in the field of rubber composite materials, can solve the problems of poor processability of lignocellulose raw materials and less research on styrene-butadiene rubber composite materials, and achieve improved mixing difficulty and processing performance, good self-healing Ability, effect of inhibiting aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

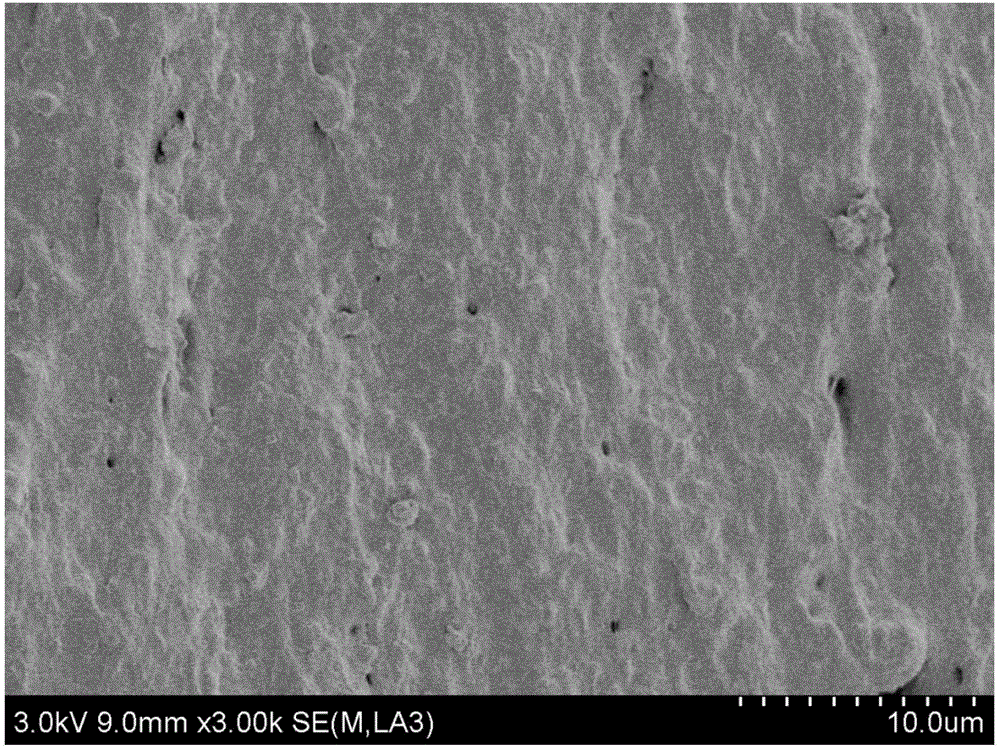

Image

Examples

Embodiment 1

[0061] The styrene-butadiene rubber / white carbon black / lignocellulose / montmorillonite rubber composite material is composed of 100 parts by weight of the raw materials: 100 parts of styrene-butadiene rubber, 30 parts of white carbon black / lignocellulose / montmorillonite composite reinforcing agent 1 part, 3 parts of zinc oxide, 1 part of stearic acid, 5 parts of paraffin oil, 1 part of vulcanizing agent, 0.6 part of accelerator NS;

[0062] White carbon black / lignocellulose / montmorillonite composite reinforcing agent is prepared by the following method:

[0063] S1: Put graphene oxide in a solvent, stir and mix, ultrasonically pulverize, centrifuge, filter, wash, and dry to obtain modified graphene oxide;

[0064] S2: Disperse the titanate coupling agent with ethyl acetate, add deionized water to dilute to obtain a dispersion, add lignocellulose to the dispersion and stir evenly, heat to 75°C and stir, add modified graphene oxide and mix and stir , filtered, washed to neutral,...

Embodiment 2

[0067] Styrene-butadiene rubber / white carbon black / lignocellulose / montmorillonite rubber composite material, its raw materials constitute by weight parts: styrene-butadiene rubber 1502 100 parts, white carbon black / lignocellulose / montmorillonite composite reinforcing agent 50 parts, 7 parts of zinc oxide, 3 parts of stearic acid, 9 parts of paraffin oil, 3 parts of sulfur, 0.9 parts of accelerator NS, 0.9 parts of accelerator TMTD, 1 part of anti-aging agent 4020;

[0068] White carbon black / lignocellulose / montmorillonite composite reinforcing agent is prepared by the following method:

[0069] S1: Put 5 parts of graphene oxide in toluene according to parts by weight, stir and mix, ultrasonically pulverize, the ultrasonic frequency is 1200Hz, and the ultrasonic time is 30min, centrifuge the obtained material, filter, wash, and dry to obtain modified graphene oxide;

[0070] S2: Disperse 4 parts of titanate coupling agent TG-38S with ethyl acetate in parts by weight, wherein th...

Embodiment 3

[0073] Styrene-butadiene rubber / white carbon black / lignocellulose / montmorillonite rubber composite material, its raw materials constitute by weight parts: styrene-butadiene rubber 1502 100 parts, white carbon black / lignocellulose / montmorillonite composite reinforcing agent 35 parts, 4 parts of zinc oxide, 1.5 parts of stearic acid, 6 parts of paraffin oil, 1.5 parts of sulfur, 0.4 parts of accelerator NS, 0.2 parts of accelerator TMTD, 0.4 parts of accelerator M, 3 parts of antioxidant OD;

[0074] White carbon black / lignocellulose / montmorillonite composite reinforcing agent is prepared by the following method:

[0075] S1: Put 5 parts of graphene oxide in toluene according to parts by weight, stir and mix, ultrasonically pulverize, the ultrasonic frequency is 1500 Hz, and the ultrasonic time is 40 min, centrifuge the obtained material, filter, wash, and dry to obtain modified graphene oxide;

[0076] S2: Disperse 12 parts by weight of titanate coupling agent TG-38S with ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com