Single-matrix single-doping white light-emitting material and preparation method and application thereof

A white light-emitting, single-substrate technology, applied in light-emitting materials, chemical instruments and methods, electrical components, etc., can solve the problems of color reproduction and luminous efficiency limitations, expensive LED chips, lack of red fluorescent components, etc. The effect of chemical stability, appropriate color coordinates, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

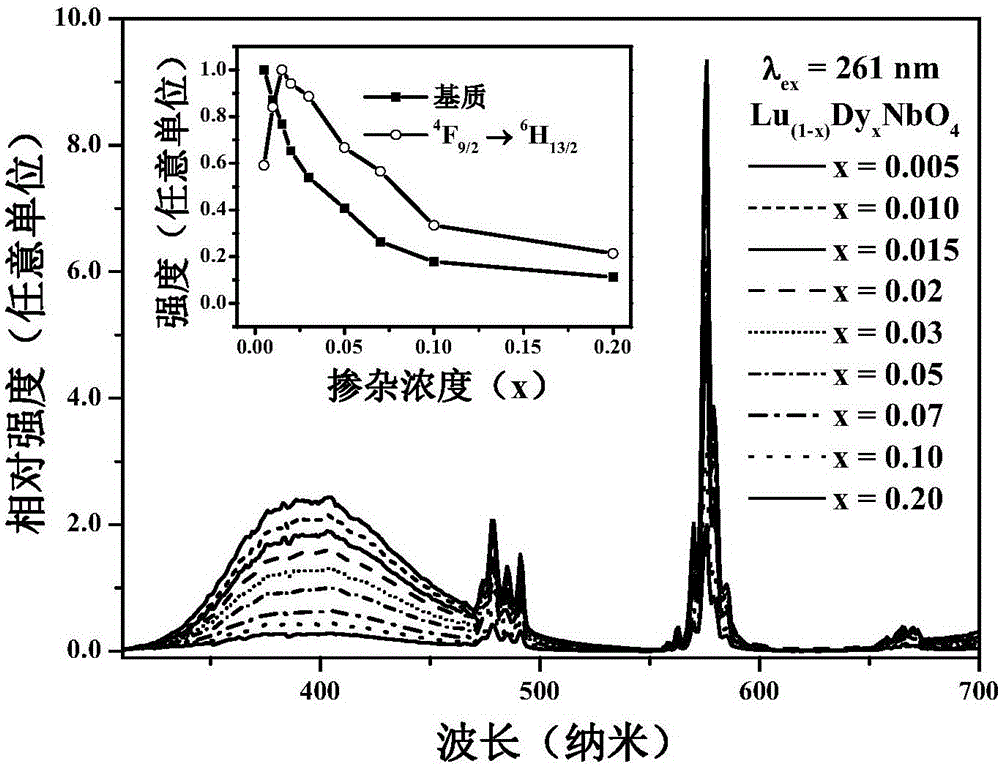

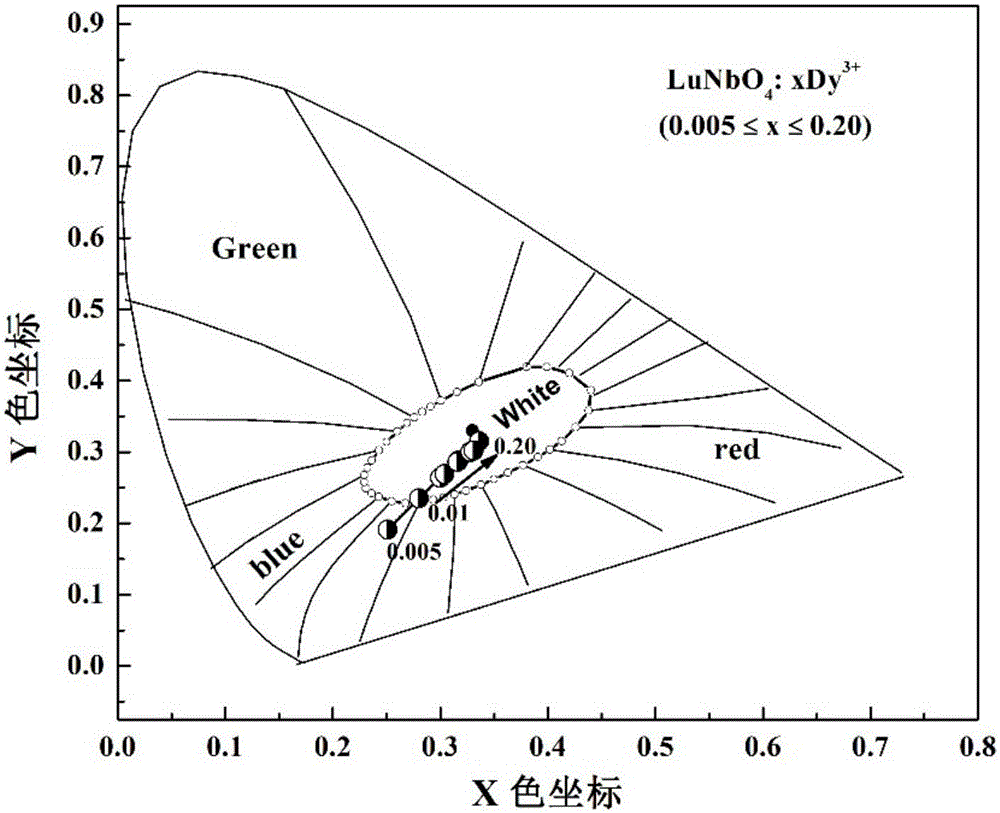

[0038] Weigh lutetium oxide (Lu 2 O 3 ) 0.5939 g, dysprosium oxide (Dy 2 O 3 ) 0.0028 g, niobium oxide (Nb 2 O 5 ) 0.3987 g, in an agate mortar, add absolute ethanol as the medium, grind and mix thoroughly; place the mixture in a cold isostatic press under a pressure of 150 MPa to form a diameter of 12.5 mm and a height of about 5 mm Cylindrical piece; Place the raw piece in a corundum crucible, in an air atmosphere, in a resistance furnace at a speed of 5 ℃ / min to 1220 ℃ for the second stage sintering, sintering time is 5h, natural cooling to room temperature; Take out and grind, and finally get the product, its chemical composition expression is: Lu 0.995 Dy 0.005 NbO 4 .

Embodiment 2

[0040] Weigh lutetium oxide (Lu 2 O 3 ) 0.5909 g, dysprosium oxide (Dy 2 O 3 ) 0.0056 g, niobium oxide (Nb 2 O 5 ) 0.3987 g, in an agate mortar, add absolute ethanol as the medium, grind and mix thoroughly; place the mixture in a cold isostatic press under a pressure of 150 MPa to form a diameter of 12.5 mm and a height of about 5 mm Cylindrical piece; Place the raw piece in a corundum crucible, in an air atmosphere, in a resistance furnace at a speed of 5 ℃ / min to 1220 ℃ for the second stage sintering, sintering time is 5h, natural cooling to room temperature; Take out and grind, and finally get the product, its chemical composition expression is: Lu 0.99 Dy 0.01 NbO 4 .

Embodiment 3

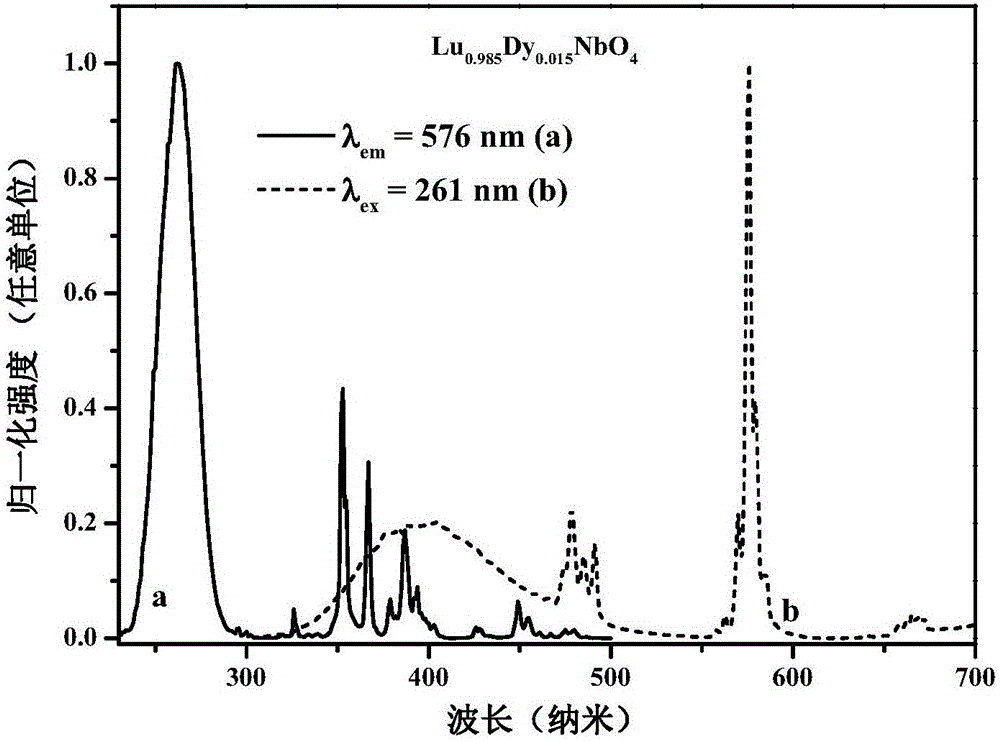

[0042] Weigh lutetium oxide (Lu 2 O 3 ) 0.5879 g, dysprosium oxide (Dy 2 O 3 ) 0.0084 g, niobium oxide (Nb 2 O 5 ) 0.3987 g, in an agate mortar, add absolute ethanol as the medium, grind and mix thoroughly; place the mixture in a cold isostatic press under a pressure of 150 MPa to form a diameter of 12.5 mm and a height of about 5 mm Cylindrical piece; Place the raw piece in a corundum crucible, in an air atmosphere, in a resistance furnace at a speed of 5 ℃ / min to 1220 ℃ for the second stage sintering, sintering time is 5h, natural cooling to room temperature; Take out and grind, and finally get the product, its chemical composition expression is: Lu 0.985 Dy 0.015 NbO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com