Method for producing clean diesel fuel through high-sulfur-nitrogen poor-quality diesel fuel

A low-quality diesel, high-sulfur technology, applied in chemical instruments and methods, processing hydrocarbon oil, petroleum industry, etc., can solve the problems of increasing equipment, difficulty in operation, and increasing cost, and achieves mild conditions, simple operation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

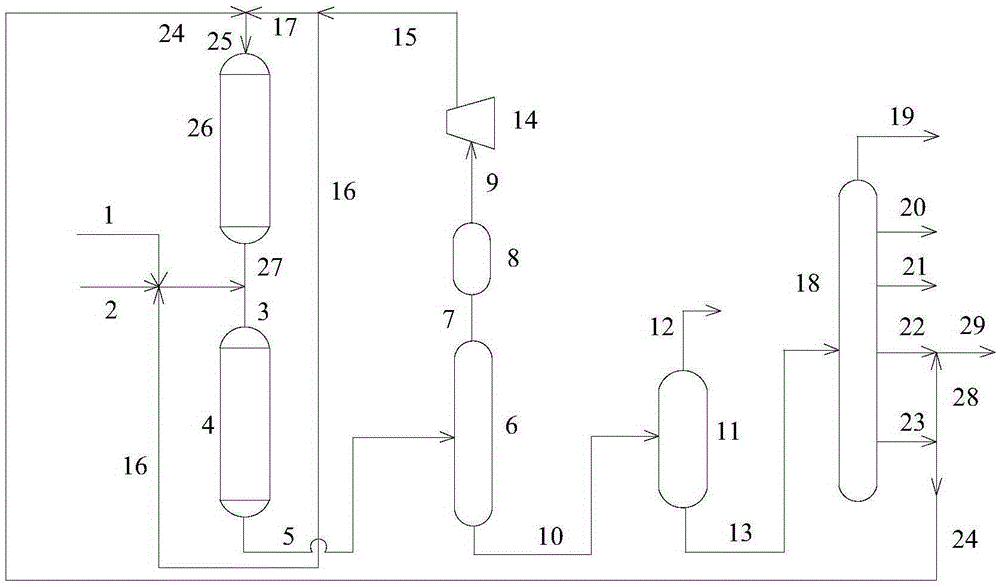

[0102] This embodiment adopts figure 1 The process flow method shown is carried out. and specifically:

[0103] The raw material oil A and the reaction product of the second hydrogenation reaction zone enter the first hydrogenation reaction zone together with new hydrogen and recycled hydrogen, and react under the action of the hydrogenation protection agent and the hydrofinishing catalyst I, and the reaction product is passed through After cooling and separation, a liquid phase and a hydrogen-containing gas phase are obtained, and the hydrogen-containing gas phase is separated and removed to obtain circulating hydrogen; the obtained liquid phase enters a fractionation system and is cut to obtain dry gas, liquefied petroleum gas, petroleum Naphtha fraction, refined diesel fraction and heavy diesel fraction, wherein the refined diesel fraction and the heavy diesel fraction have a cut point of 320°C, 75% by weight (relative to the total weight of all produced heavy diesel fract...

Embodiment 2

[0106] This embodiment adopts figure 1 The process flow method shown is carried out. and specifically:

[0107] The raw material oil A and the reaction product of the second hydrogenation reaction zone enter the first hydrogenation reaction zone together with new hydrogen and recycled hydrogen, and react under the action of the hydrogenation protection agent and the hydrofinishing catalyst I, and the reaction product is passed through After cooling and separation, a liquid phase and a hydrogen-containing gas phase are obtained, and the hydrogen-containing gas phase is separated and removed to obtain circulating hydrogen; the obtained liquid phase enters a fractionation system and is cut to obtain dry gas, liquefied petroleum gas, petroleum Naphtha fractions, refined diesel fractions and heavy diesel fractions, wherein the refined diesel fraction and the heavy diesel fraction have a cut point of 300°C, 50% by weight (relative to the total weight of all produced heavy diesel fr...

Embodiment 3

[0110] This embodiment adopts figure 1 The process flow method shown is carried out. and specifically:

[0111] The raw material oil A and the reaction product of the second hydrogenation reaction zone enter the first hydrogenation reaction zone together with new hydrogen and recycled hydrogen, and react under the action of the hydrogenation protection agent and the hydrofinishing catalyst I, and the reaction product is passed through After cooling and separation, a liquid phase and a hydrogen-containing gas phase are obtained, and the hydrogen-containing gas phase is separated and removed to obtain circulating hydrogen; the obtained liquid phase enters a fractionation system and is cut to obtain dry gas, liquefied petroleum gas, petroleum Naphtha fraction, refined diesel fraction and heavy diesel fraction, wherein the refined diesel fraction and the heavy diesel fraction have a cut point of 330°C, 90% by weight (relative to the total weight of all produced heavy diesel fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com