Preparation method of iron-cerium-based porous catalyst used for removing organic sulfur

An organosulfur and catalyst technology, which is used in the preparation of cerium porous materials, iron-cerium-based porous catalysts, and iron-containing fields, can solve problems such as unreported process methods, and achieve short preparation time, strong adsorption capacity, and high specificity. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix ferric nitrate and cerium nitrate in a mass ratio of 1:10 to obtain mixed nitrate; mix MIL-100 (Fe) and mixed nitrate in a mass ratio of 1:3, add deionized water and stir for 3 Hour, get the mixed solution; put the above-mentioned mixed solution in a blast drying box, dried at 130 ℃ for 8 hours; put the dried mixture in a quartz boat and placed in a tube furnace, in an oxygen-enriched atmosphere and 700 It is calcined at ℃ for 2 hours to obtain iron-cerium-based porous catalyst.

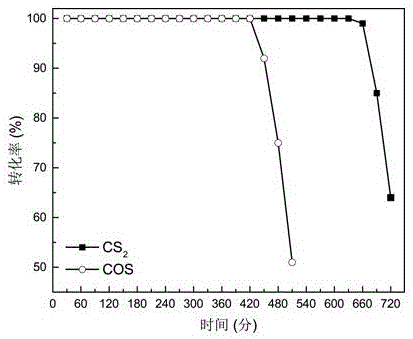

[0028] The catalyst activity test was carried out in a fixed-bed quartz reactor, and the reaction conditions were: COS concentration 500ppm, CS 2 Concentration 50ppm, space velocity 50000h -1 、Reaction temperature 60℃, oxygen content 5%, COS and CS 2 See the catalytic conversion results figure 1 , It can be concluded from the figure that 100% COS conversion rate can be maintained for 420min, 100% CS 2 The conversion rate can be maintained for 630 minutes, which indicates that the iron-cerium-b...

Embodiment 2

[0030] Mix ferric nitrate and cerium nitrate in a mass ratio of 1:5 to obtain mixed nitrate; mix Fe-MOF-5 and mixed nitrate in a mass ratio of 1:0.5, add deionized water and stir for 4 hours , Get the mixed solution; place the above mixed solution in a blast drying box and dry at 150°C for 9 hours; put the dried mixture in a quartz boat and place it in a tube furnace, in an oxygen-rich atmosphere and 500°C After calcination for 4 hours, an iron-cerium-based porous catalyst is obtained.

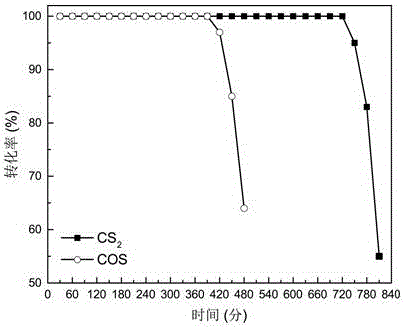

[0031] The catalyst activity test was carried out in a fixed-bed quartz reactor, and the reaction conditions were: COS concentration 500ppm, CS 2 Concentration 50ppm, space velocity 50000h -1 、Reaction temperature 60℃, oxygen content 5%, COS and CS 2 See the catalytic conversion results figure 2 From the figure, it can be concluded that 100% COS conversion rate can be maintained for 390min, 100% CS 2 The conversion rate can be maintained for 720min, which indicates that the iron-cerium-based poro...

Embodiment 3

[0033] Mix ferric nitrate and cerium nitrate in a mass ratio of 1:20 to obtain mixed nitrate; mix Fe-MOF-74 and mixed nitrate in a mass ratio of 1:1.5, add deionized water and stir for 5 hours , The mixed solution is obtained; the above-mentioned mixed solution is placed in a blast drying box and dried at 100°C for 7 hours; the dried mixture is placed in a quartz boat and placed in a tube furnace, in an oxygen-rich atmosphere and 400°C After calcination for 5 hours, the iron-cerium-based porous catalyst is obtained.

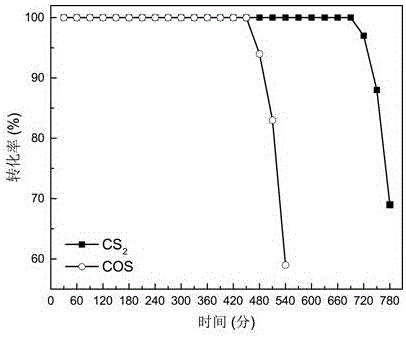

[0034] The catalyst activity test was carried out in a fixed-bed quartz reactor, and the reaction conditions were: COS concentration 500ppm, CS 2 Concentration 50ppm, space velocity 50000h -1 、Reaction temperature 60℃, oxygen content 5%, COS and CS 2 See the catalytic conversion results image 3 From the figure, it can be concluded that 100% COS conversion rate can maintain 450min, 100% CS 2 The conversion rate can be maintained for 690 min, which indicates that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com