Synthesis method of MoS2 nano-structure material

A synthesis method and nanostructure technology, applied in the field of synthesis of MoS2 nanostructure materials, can solve the problems of low product efficiency, difficulty in adapting to the development trend and actual needs of nanostructure materials, acid waste water pollution, etc., and achieve the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

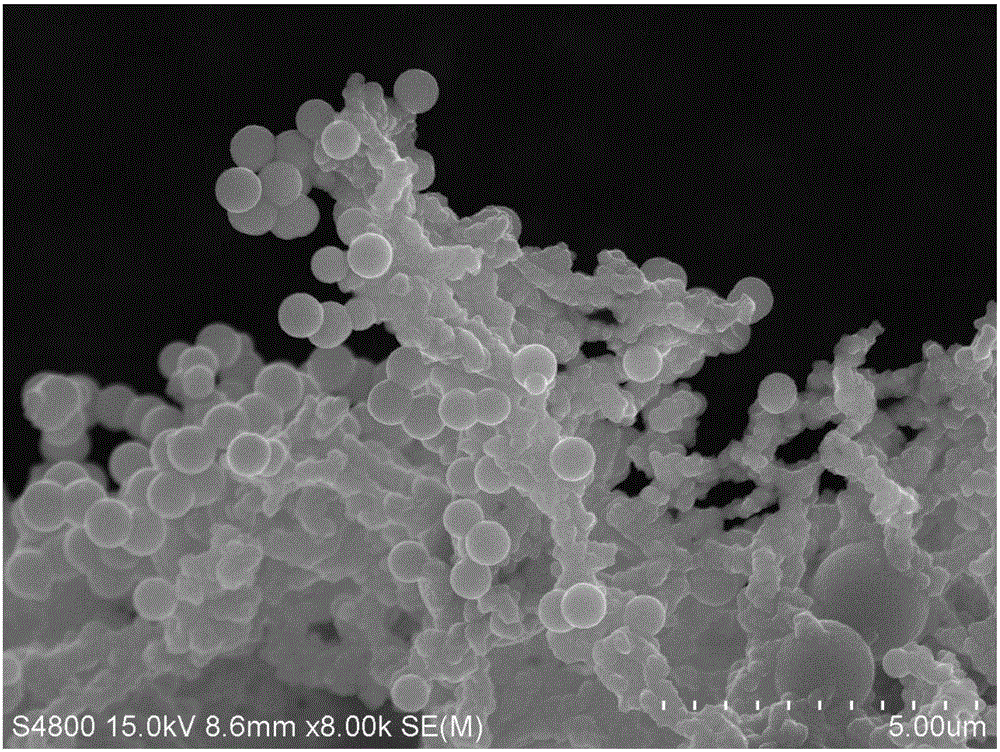

[0056] A kind of MoS 2 The synthesis method of the nanostructure material, the synthesis steps are as follows: each component is calculated by mass, dissolves 25 parts of molybdenum pentachloride in 500 parts of ethanol, stirs on a magnetic stirrer for 0.5 to 1 hour, after completely dissolving, takes 40 parts of the molybdenum pentachloride The solution was transferred into a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a capacity of 80 parts, sealed, put into an oven, and heated at 180° C. for 20 hours to obtain the precursor molybdenum dioxide. Get 100 parts of molybdenum dioxide and dissolve it in 40 parts of n-hexanol, then add 15 parts of L-cysteine solution therein, stir on a magnetic stirrer for 1 hour, and transfer the resulting black suspension into a tank with a capacity of 80 parts. Teflon-lined stainless steel hydrothermal reaction kettle, after sealing, put it into an oven and heat it at 120°C for 20 hours. After the reaction...

Embodiment 2

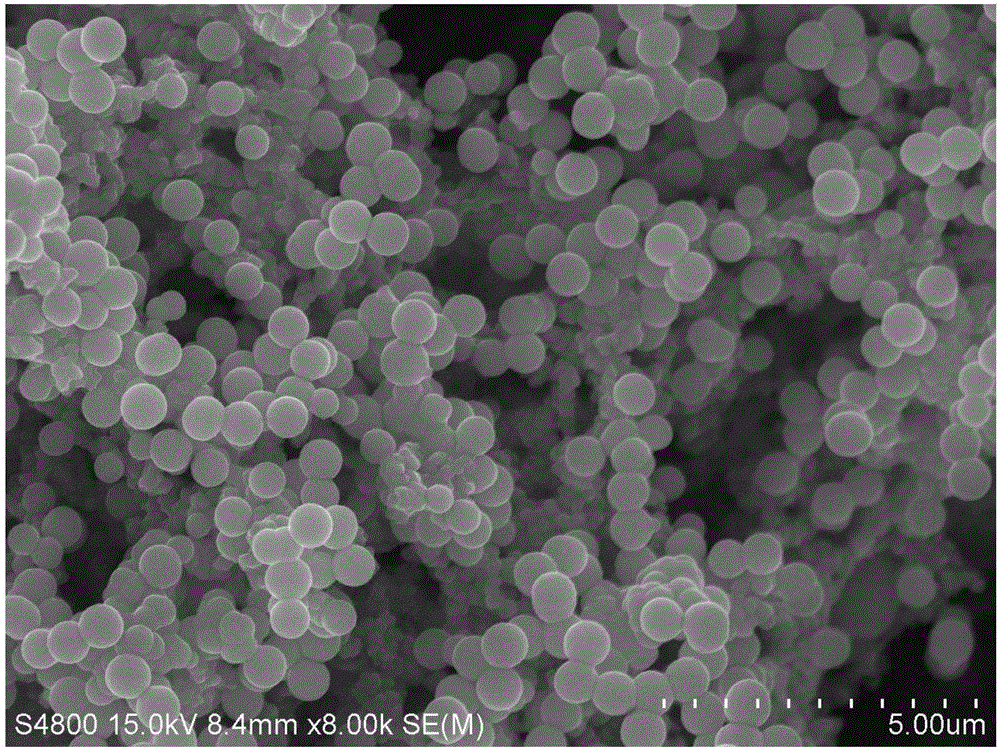

[0058] A kind of MoS 2 The synthesis method of the nanostructure material, the synthesis steps are as follows: each composition is calculated by mass, 25 parts of molybdenum pentachloride are dissolved in 500 parts of ethanol, stirred on a magnetic stirrer for 0.5 hour, after dissolving completely, get 40 parts of this solution and transfer to Put it into a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a capacity of 80 parts, seal it, put it into an oven, and heat it at 180°C for 20 hours to obtain the precursor molybdenum dioxide. Get 100 parts of molybdenum dioxide and dissolve it in 40 parts of n-hexanol, then add 15 parts of L-cysteine solution therein, stir on a magnetic stirrer for 1 hour, and transfer the resulting black suspension into a tank with a capacity of 80 parts. Teflon-lined stainless steel hydrothermal reaction kettle, after sealing, put it into an oven and heat it at 150°C for 20 hours. After the reaction, the stainless s...

Embodiment 3

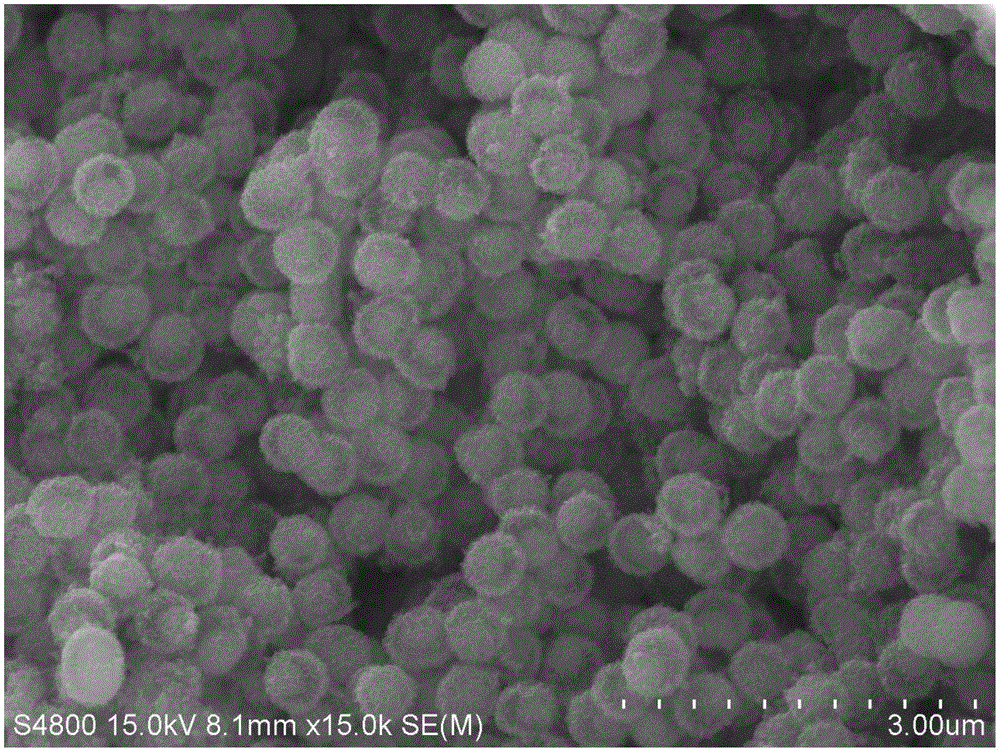

[0060] A kind of MoS 2 The synthesis method of the nanostructure material, the synthesis steps are as follows: each composition is calculated by mass, 25 parts of molybdenum pentachloride are dissolved in 500 parts of ethanol, stirred on a magnetic stirrer for 0.5 hour, after dissolving completely, get 40 parts of this solution and transfer to Put it into a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle with a capacity of 80 parts, seal it, put it into an oven, and heat it at 180°C for 20 hours to obtain the precursor molybdenum dioxide. Get 100 parts of molybdenum dioxide and dissolve it in 40 parts of n-hexanol, then add 15 parts of L-cysteine solution therein, stir on a magnetic stirrer for 1 hour, and transfer the resulting black suspension into a tank with a capacity of 80 parts. PTFE-lined stainless steel hydrothermal reaction kettle, after sealing, put it into an oven and heat it at 180°C for 20 hours. After the reaction, the stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com