Urban resident household kitchen garbage cyclic utilization system and method

A technology for kitchen waste and residents, applied in the field of kitchen waste recycling system for urban residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

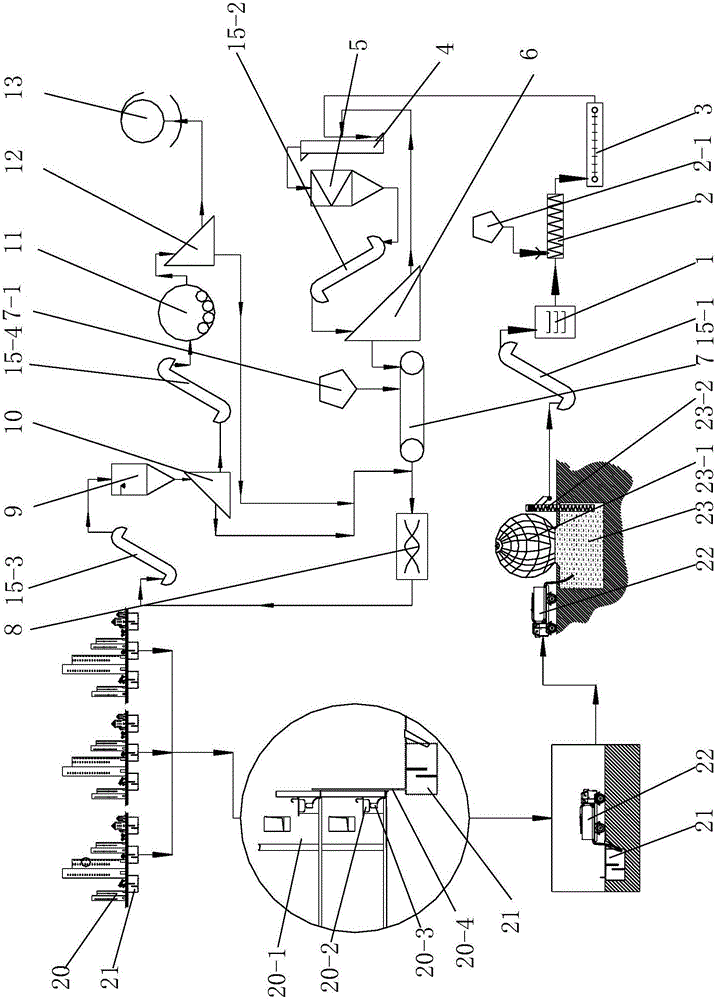

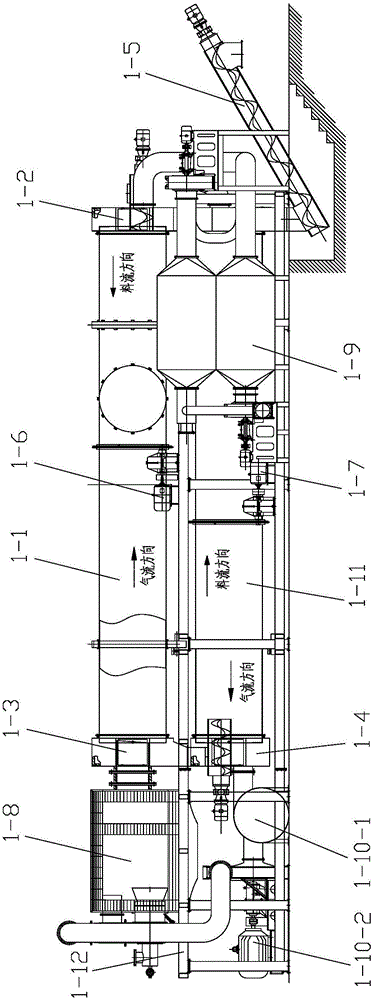

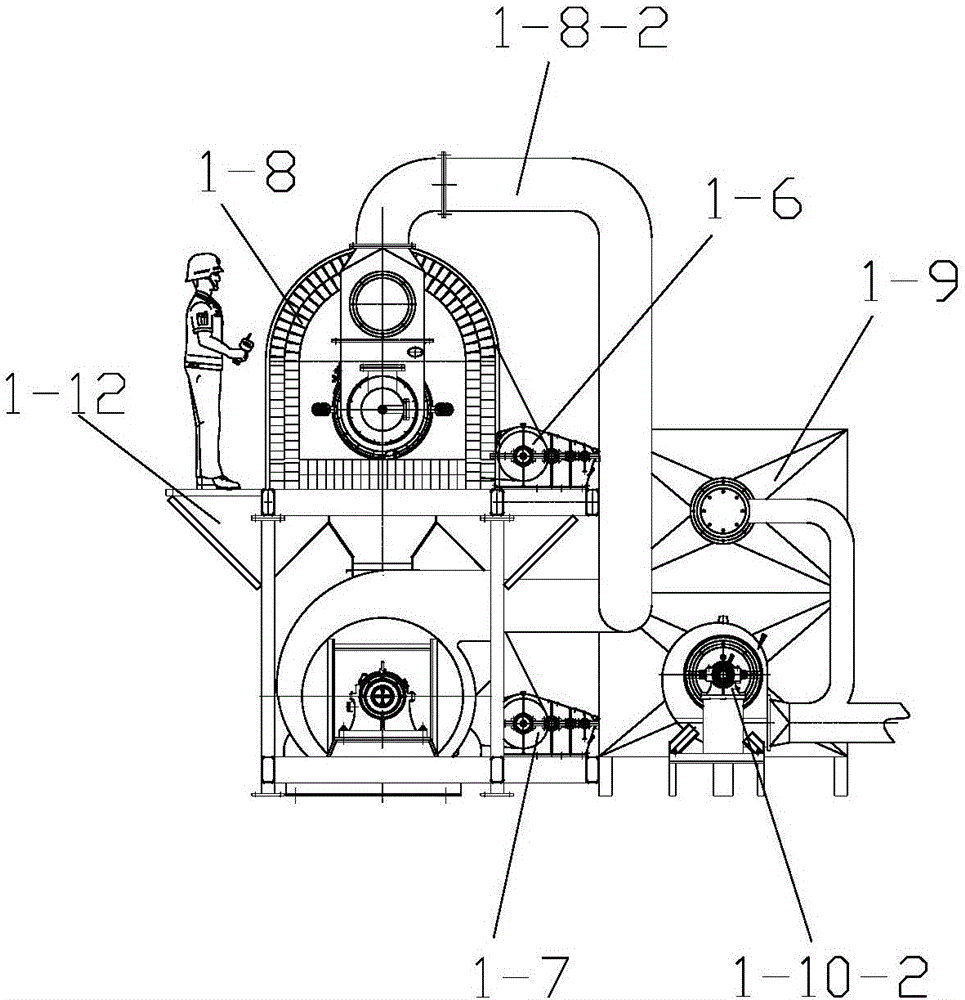

[0105] Such as figure 1 The shown kitchen waste recycling system for urban residents includes a first sealed shaftless screw conveyor 15-1, a rotary drum dryer 1, a screw mixing conveyor 2, Drum composter 3, bucket elevator 4, compost tower 5, second sealed shaftless screw conveyor 15-2, primary screening machine 6, belt conveyor 7, mixing mixer 8, third sealed shaftless screw conveyor Shaft screw conveyor 15-3, granulator 9, secondary screening machine 10, fourth sealed shaftless screw conveyor 15-4, particle dryer 11, tertiary screening machine 12 and product packaging machine 13; The outlets of the screening machine 6, the secondary screening machine 10 and the third screening machine 12 all include an oversize outlet and an undersize outlet; the undersize outlet of the primary screening machine 6 passes through the pipeline and the belt conveyor 7 The undersize outlet of the secondary screening machine 10 is connected to the fourth sealed shaftless screw conveyor 15-4 thr...

Embodiment 2

[0129] combine figure 1 In this embodiment, the method for recycling urban household kitchen waste by using the system as described in Embodiment 1 includes the following steps:

[0130] Step 1. The biogas residue obtained after anaerobic fermentation of household kitchen waste of urban residents is transported to the drum dryer 1 by the first sealed shaftless screw conveyor 15-1, and then dried to the drum dryer. A high-temperature airflow with a temperature of 500°C is introduced into the machine 1, and the high-temperature airflow is in reverse contact with the biogas residue to obtain a slurry material; the moisture content of the biogas residue is 83%; the material temperature of the slurry material is 56°C , the moisture content is 67%;

[0131] The specific process of obtaining biogas residues after anaerobic fermentation of household kitchen waste of urban residents described in this embodiment is as follows: First, the kitchen waste of urban households is put into th...

Embodiment 3

[0142] to combine figure 1 In this embodiment, the method for recycling urban household kitchen waste by using the system as described in Embodiment 1 includes the following steps:

[0143] Step 1. The biogas residue obtained after anaerobic fermentation of household kitchen waste of urban residents is transported to the drum dryer 1 by the first sealed shaftless screw conveyor 15-1, and then dried to the drum dryer. A high-temperature airflow with a temperature of 800°C is introduced into the machine 1, and the high-temperature airflow is in reverse contact with the biogas residue to obtain a slurry material; the moisture content of the biogas residue is 85%; the material temperature of the slurry material is 60°C , with a moisture content of 70%;

[0144] The specific process of obtaining biogas residues after anaerobic fermentation of household kitchen waste of urban residents described in this embodiment is as follows: First, the kitchen waste of urban households is put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com