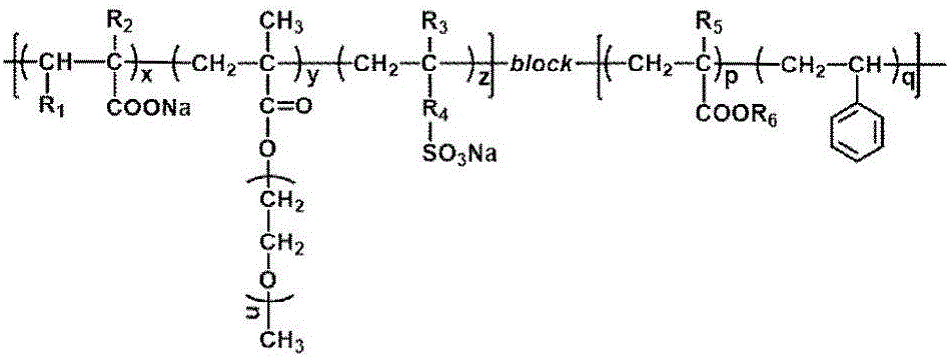

Nanometer polycarboxylic acid water reducer and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of nano polycarboxylate water reducer and its preparation, which can solve the problems of insignificant anti-mud effect, low water-reducing performance, cumbersome steps, etc., and achieve excellent mud-resistance performance , High water reduction rate, not easy to agglomerate and precipitate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

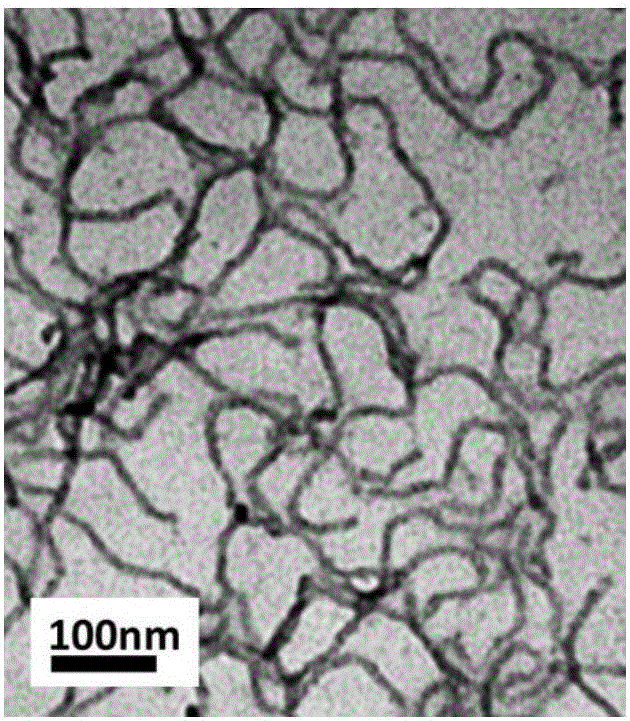

Image

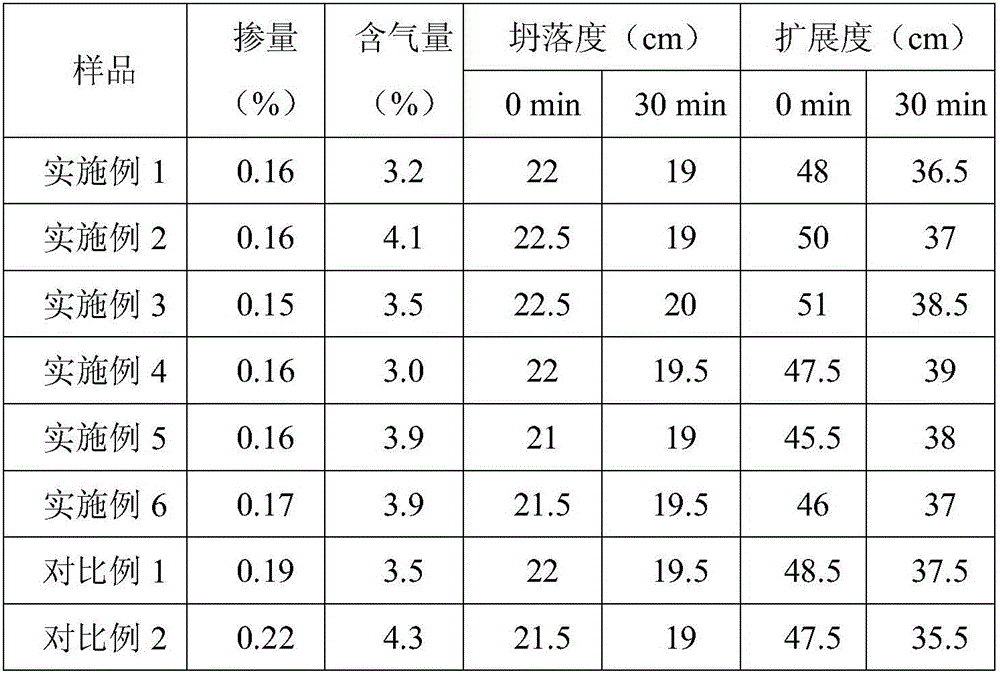

Examples

Embodiment 1

[0049] In the flask that stirrer is housed, add small molecule RAFT reagent EMP5.04g, polyethylene glycol monomethyl ether methacrylate macromonomer (M w =500) 150g, acrylic acid 25.9g+itaconic acid 31.2g, sodium methallylsulfonate 11.85g, V-50 initiator 2.03g (the molar ratio of raw materials is 3:40:48+32::1) and 151g of water is fully mixed, and the polymerization concentration is 60% at this time, and the 2 Under the atmosphere, the temperature was raised to 60 ° C, and after 2 hours of reaction, the macromolecular RAFT reagent aqueous solution MR01 was obtained, the monomer conversion rate was 98.5%, and the molecular weight was M w for 10800.

[0050] Add 648g of hydrophobic monomer propyl methacrylate and 1153g of water to MR01, stir at a speed of 1000rpm for 30min to form a stable emulsion, then add 10g of aqueous solution containing 1.02g of V-50 initiator, at this time MR01, hydrophobic monomer and initiator The molar ratio of the agent is 6:1350:1, the polymerizat...

Embodiment 2

[0052] In the flask that stirrer is housed, add small molecule RAFT reagent BDMAT4.03g, polyethylene glycol monomethyl ether methacrylate macromonomer (M w =800) 160g, acrylic acid 42.2g+fumaric acid 17g, sodium styrene sulfonate 13.7g, V-501 initiator 1.32g (raw material molar ratio is 3:45:132+33:14:1) and water 225g fully Mixing, at this time the polymerization concentration is 50%, in N 2 Under the atmosphere, the temperature was raised to 70 ° C, and after 3 hours of reaction, the macromolecular RAFT reagent aqueous solution MR02 was obtained, the monomer conversion rate was 99.0%, and the molecular weight was M w is 15300;

[0053] Add 370g of hydrophobic monomer styrene and 1550g of water in MR02, after stirring at a speed of 1000rpm for 30min to form a stable emulsion, then add 10g of aqueous solution containing 1.15g of VA-044 initiator. At this time, the moles of MR02, hydrophobic monomer and initiator The ratio is 4:1000:1, the polymerization concentration is 25%,...

Embodiment 3

[0055] In the flask that stirrer is housed, add small molecule RAFT reagent BDMAT3.53g, polyethylene glycol monomethyl ether methacrylate macromonomer (M w =1000) 200g, acrylic acid 36g, 2-acrylamide-2-sodium methylpropanesulfonate 10.4g, potassium persulfate initiator 0.844g (the molar ratio of raw materials is 4:64:160:16:1) and water 376g Mix well, at this time the polymerization concentration is 40%, in N 2 Under the atmosphere, the temperature was raised to 80°C, and after 4 hours of reaction, the macromolecular RAFT reagent aqueous solution MR03 was obtained, the monomer conversion rate was 99.3%, and the molecular weight was M w is 19400;

[0056] Add hydrophobic monomer tert-butyl methacrylate 356g and water 1030g in MR03, after stirring 30min under the speed of 1000rpm to form stable emulsion, then add the aqueous solution 10g that contains 0.845g potassium persulfate initiator, now MR03, hydrophobic monomer and The molar ratio of the initiator is 4:800:1, the polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com