High-performance polyoxometalate catalyst and producing method therefor

一种多金属氧酸盐、催化剂的技术,应用在催化剂活化/制备、羧酸盐制备、金属/金属氧化物/金属氢氧化物催化剂等方向,达到卓越再现性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

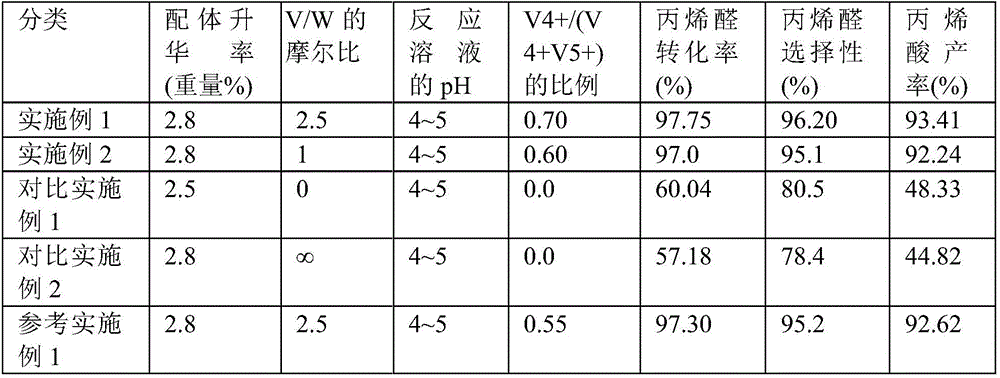

Examples

Embodiment 1

[0117] While stirring 3000ml of 100°C distilled water, add 246g of ammonium tungstate, 1,000g of ammonium molybdate and 12g of niobium oxalate (NbC 2 o 4 ), thereby preparing a solution (1) consisting of Mo, A and B components of formula 1. 276 g of vanadyl sulfate was individually dissolved in 1000 ml of distilled water to prepare a solution (2).

[0118] Solution (1) was mixed with solution (2), then 570 g of Cu(CH 3 COO) 2 ·H 2 O, 99 g of strontium nitrate, 23 g of manganese nitrate and 95 g of ferric nitrate as components C and D of Formula 1, thereby preparing a suspension. The pH of the suspension was adjusted to 4 to 5 using diluted sulfuric acid, and the homogenizer was run until the polyoxometalate formed a slurry in which the viscosity had increased sufficiently.

[0119] Subsequently, the slurry polyoxometalate was coated on a spherical support, aluminosilicate (Saint Gobain, SA5218) with an outer diameter of 4.0 mm to 8.0 mm, through a nozzle, and fully dried ...

Embodiment 2

[0123] A polyoxometalate catalyst was prepared in the same manner as in Example 1 except that ammonium tungstate in an amount of 123 g was used. The composition of the elements of the resulting catalyst component, other than oxygen, was as follows:

[0124] Mo 12 V 5.0 W 5.0 Nb 0.1 Cu 5.0 Sr 1.0 mn 0.2 Fe 0.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com