Vitamin C microcapsule and preparation method thereof

A technology of vitamins and microcapsules, which is applied in the directions of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of reducing the efficacy of vitamin C, and achieve the effects of promoting absorption and penetration, good biocompatibility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

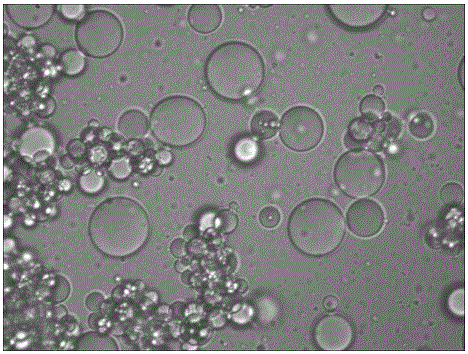

Image

Examples

Embodiment 1

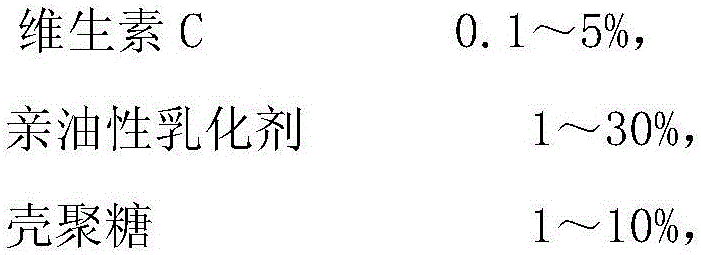

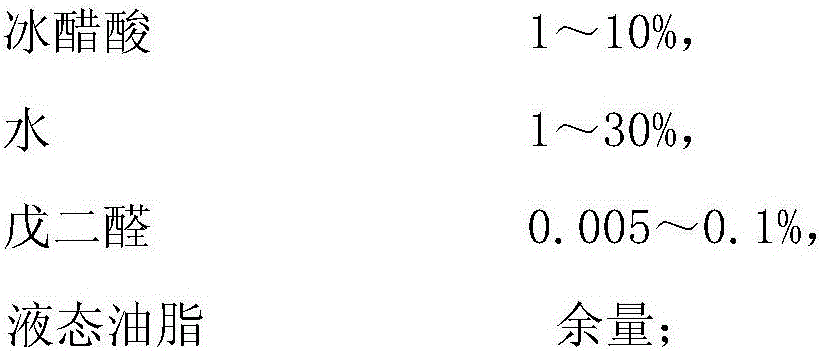

[0047] Based on 1000g of formula raw materials, take 1g of vitamin C, 10g of lipophilic emulsifier, 10g of chitosan, 10g of glacial acetic acid, 10g of water, 0.05g of glutaraldehyde, and 958.95g of liquid oil.

[0048] Described lipophilic emulsifier is ceteareth-6;

[0049] The liquid oil is caprylic capric triglyceride;

[0050] The steps of preparation method are as follows:

[0051] 1) glacial acetic acid is dissolved in water to make acetic acid solution;

[0052] 2) Chitosan is added to the acetic acid solution prepared in step 1), heated at 30° C. to dissolve completely, and the chitosan acetic acid solution is obtained after standing to remove air bubbles;

[0053] 3) Add vitamin C to the solution prepared in step 2), and stir evenly at 25°C to obtain the first solution;

[0054]4) Add the lipophilic emulsifier into the liquid oil, and stir evenly in a constant temperature water bath at 25°C to obtain the second solution;

[0055] 5) Heating the second solution at...

Embodiment 1

[0059] Embodiment 1 comparative example:

[0060] That is to configure 1% vitamin C aqueous solution.

[0061] The vitamin C microcapsules obtained in the above-mentioned embodiment 1 and the comparative example of embodiment 1 obtained contain 1% vitamin C aqueous solution permeability data measurement, the results are shown in the following table:

[0062]

Embodiment 2

[0064] Based on 1000g of formula raw materials, take 50g of vitamin C, 300g of lipophilic emulsifier, 100g of chitosan, 100g of glacial acetic acid, 300g of water, 1g of glutaraldehyde, and 149g of liquid oil.

[0065] Described lipophilic emulsifier is ceteareth-25;

[0066] Described liquid grease is isopropyl myristate;

[0067] The steps of preparation method are as follows:

[0068] 1) glacial acetic acid is dissolved in water to make acetic acid solution;

[0069] 2) Chitosan is added to the acetic acid solution prepared in step 1), heated at 60° C. to completely dissolve, and the chitosan acetic acid solution is obtained after standing to remove air bubbles;

[0070] 3) Add vitamin C to the solution prepared in step 2), and stir at 50°C to obtain the first solution;

[0071] 4) Add the lipophilic emulsifier into the liquid oil, and stir evenly in a constant temperature water bath at 60°C to obtain the second solution;

[0072] 5) Heating the second solution at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com