Simple and convenient method for preparing three-dimensional nitrogen-doped graphene

A nitrogen-doped graphene, three-dimensional technology, used in chemical instruments and methods, hybrid/electric double-layer capacitor manufacturing, electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

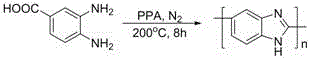

[0017] [Example 1] Preparation of ABPBI (method 1, solid-phase method): Take an appropriate amount of 3,4-diaminobenzoic acid (DABA) in a mortar, grind it thoroughly and transfer it to a three-necked flask with electric stirring and inert gas protection Inside, blow nitrogen for 15 minutes to exhaust the air in the flask. N 2 Under protection, under stirring, the oil bath was heated to 225°C and kept for 3h. Take it out after cooling, grind finely, N 2 Under protection, heat in an electric furnace, then raise the temperature to 270-275°C and keep for 3h. After cooling to room temperature, the product was taken out and finely ground to obtain ABPBI, and the molecular weight of ABPBI was measured with an Ubbelohde viscometer.

Embodiment 2

[0018] [Example 2] Preparation of ABPBI (method 2, liquid phase method): polyphosphoric acid (PPA) (50 g) was added into a three-necked flask, and stirred at 160° C. for 1 h under nitrogen protection to remove water and air. 3,4-diaminobenzoic acid (6 g, 39.5 mmol) was added and the temperature was raised to 190 °C, controlled by N 2Flow rate, to prevent DABA from being oxidized, continue to stir for 3h, add about 5g P in batches during the reaction 2 o 5 To absorb the water formed during the reaction. With the increase of reaction time, the polymerization system gradually became viscous. The reaction mixture was slowly transferred to deionized water, spinning to form a fibrous black solid, which was taken out and dried, crushed, and washed to remove polyphosphoric acid and unreacted raw materials in the reaction mixture. Get ABPBI products. The molecular weight of ABPBI was determined with an Ubbelohde viscometer.

Embodiment 3

[0019] [embodiment 3] SiO with particle diameter 30nm 2 Three-dimensional porous nitrogen-doped graphene was prepared by pyrolyzing the template agent mixed with ABPBI. With ABPBI and SiO 2 The template mass ratio is 1:1 as an example: In a 250mL beaker, add 1g of ABPBI (viscosity average molecular weight 20,000 to 30,000) and 20mL of DMAc, heat and stir to dissolve, and slowly add 1g of SiO while stirring 2 Nanoparticles with a particle size of 30nm make it uniformly dispersed. The obtained viscous liquid is heated and concentrated to nearly dryness under stirring, and dried in a vacuum oven at 100°C. The solid is ground in a mortar, transferred to a porcelain boat, and kept in a high-temperature electric furnace at 900°C under the protection of argon. Pyrolyze for 2-3 hours, wait for the furnace temperature to drop to room temperature, take it out, and grind it finely to obtain a black powdery solid, transfer it to a 250mL Erlenmeyer flask, add 70mL of hydrofluoric acid, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com