Niobium hydroxide visible-light-driven photocatalyst having wide-spectral catalytic performance and grafting with aromatic alcohol on surface, and preparation and application thereof

A technology of niobium hydroxide and catalytic performance, applied in the field of photocatalyst synthesis, can solve problems such as preparation methods that have not yet been reported, and achieve the effects of easy regulation of light absorption properties, easy regulation of photocatalytic activity, and excellent charge transfer ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a niobium hydroxide visible light catalyst grafted with aryl alcohol on the surface with broad-spectrum catalytic performance, comprising the following steps:

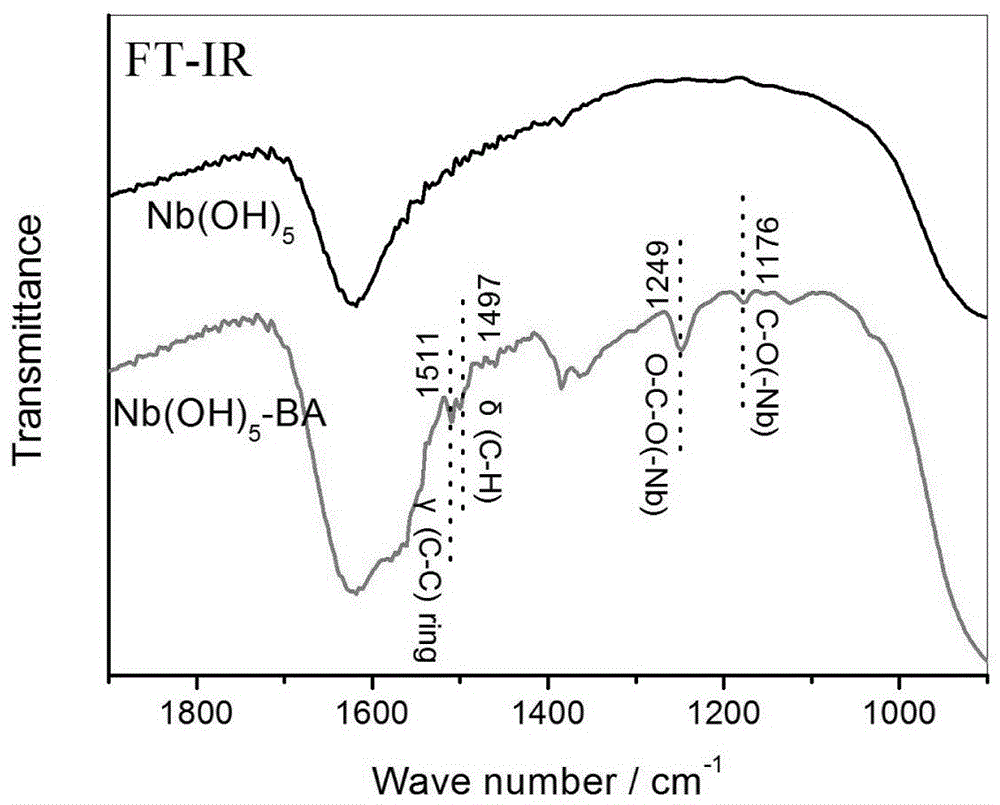

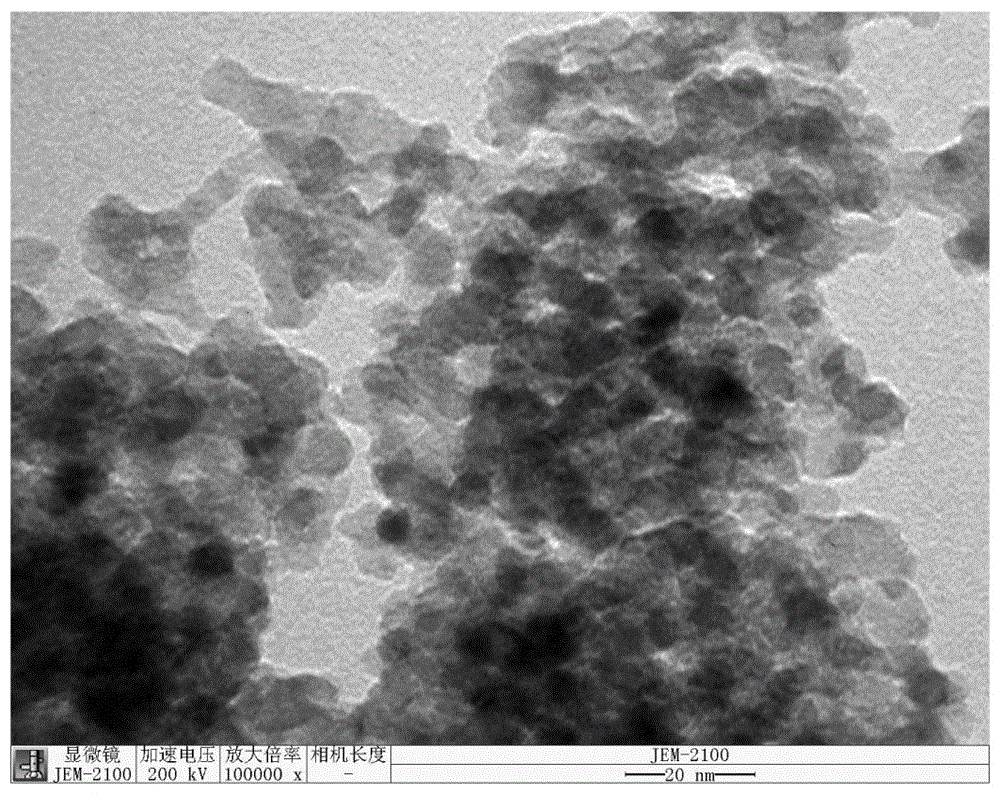

[0031] Add 2 g of NbCl to 100 mL of deionized water 5 , the resulting mixture was placed in a 130°C oil bath with a condensing reflux device to react for 6 hours. After the reaction, the solid obtained was centrifuged, washed with distilled water three times, and dried at 60°C to obtain white Nb(OH) 5 powder; then the obtained 1.5g of niobium hydroxide was added to 80mL of benzyl alcohol BA, and ultrasonically dispersed for 30 minutes, and the resulting mixed suspension was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, and after sealing Place in a drying oven at 150°C for solvent heat treatment for 12 hours; after cooling the reactor at room temperature, centrifuge the resulting precipitate, wash with n-hexane and acetone three times respectively, and dry a...

Embodiment 2

[0047] A method for preparing a niobium hydroxide visible light catalyst grafted with aryl alcohol on the surface with broad-spectrum catalytic performance, comprising the following steps:

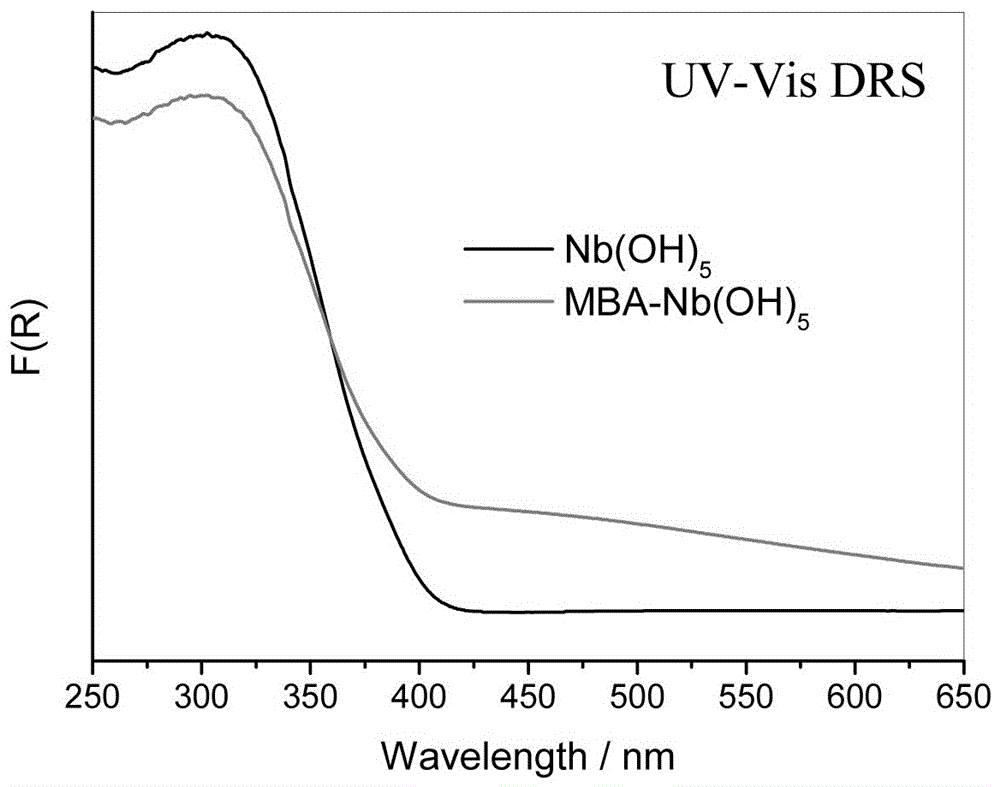

[0048] Add 1 g of NbCl to 100 mL of deionized water 5 , the resulting mixed solution was placed in a 150°C oil bath with a condensing reflux device to react for 3 hours. After the reaction, the solid obtained was centrifuged, washed with distilled water for 3 times, and dried at 60°C to obtain a white niobium hydroxide powder; then 2.4g of niobium hydroxide was added into 60mL of 4-methoxybenzyl alcohol MBA, and ultrasonically dispersed for 30 minutes, and the resulting mixed suspension was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, sealed and placed Solvent heat treatment was carried out in a drying oven at 120°C for 24 hours; after the reaction kettle was cooled at room temperature, the obtained precipitate was centrifuged, washed three times with n-he...

Embodiment 3

[0051] A method for preparing a niobium hydroxide visible light catalyst grafted with aryl alcohol on the surface with broad-spectrum catalytic performance, comprising the following steps:

[0052] Add 3 g of NbCl to 100 mL of deionized water 5 , the resulting mixture was placed in a 110°C oil bath with a condensing reflux device to react for 9 hours. After the reaction, the resulting solid was centrifuged, washed with distilled water three times, and dried at 60°C to obtain a white niobium hydroxide powder; then Add 0.5g of the prepared niobium hydroxide into 50mL of 1-phenylethyl alcohol 1-PEA, ultrasonically disperse for 30 minutes, transfer the resulting mixed suspension to a stainless steel reactor with a polytetrafluoroethylene liner, seal it and place it in a dry place Solvent heat treatment was carried out at 180°C in the box for 8 hours; after the reaction kettle was cooled at room temperature, the obtained precipitate was centrifuged, washed three times with n-hexane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com