Ultrahigh specific surface area mesoporous carbon nanosphere as well as preparation method and application thereof

A technology of ultra-high specific surface area, mesoporous carbon, applied in nano-carbon and other directions, can solve problems such as environmental pollution, high equipment requirements, and material structure collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

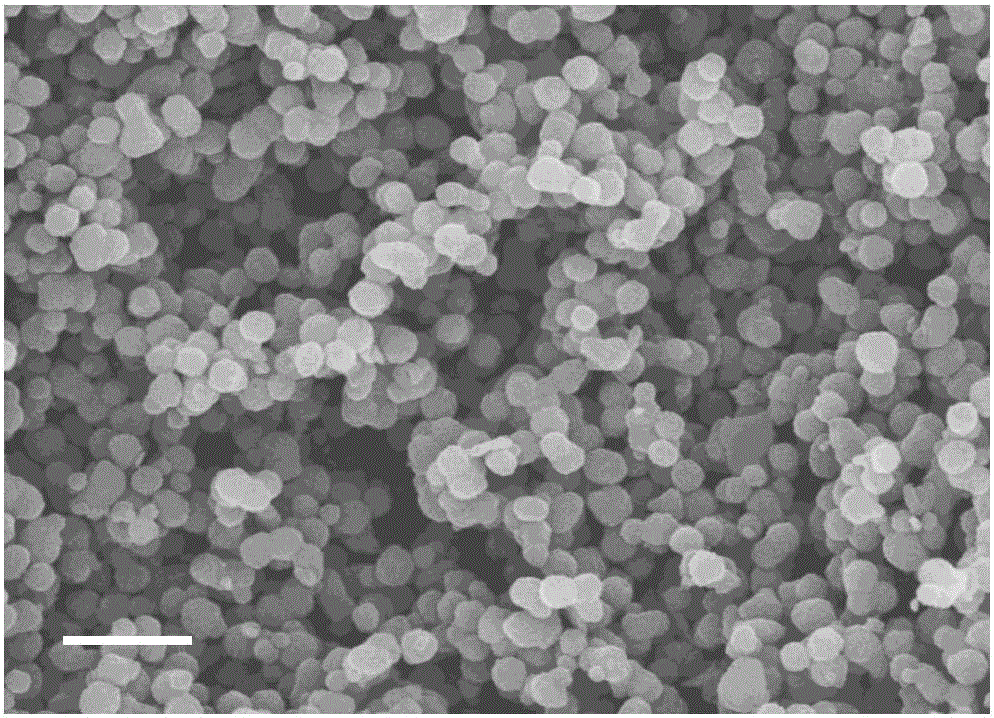

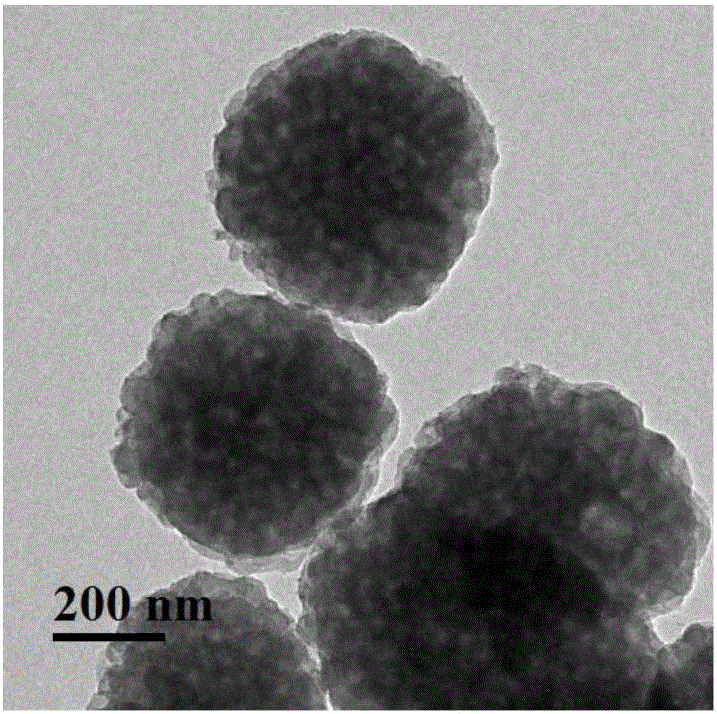

[0077] The embodiment of the present invention provides a method for preparing mesoporous carbon nanospheres with ultra-high specific surface area, comprising the following steps:

[0078] (1) Dissolve 0.17ml of aniline and 0.13ml of pyrrole in 12ml of ethanol / water mixed solvent (the volume ratio of ethanol and water is 1:2) to form solution 1; 30mg of PEO 113 -b-PS 445 Dissolve in 4ml tetrahydrofuran to form solution 2, then add solution 1 to solution 2 to self-assemble to obtain a light blue emulsion; after magnetic stirring for 0.5h, then ultrasonically disperse for 0.5h, then place in an ice-water bath and continue stirring for 0.5h , then, add 2ml of 0.41g / ml ammonium persulfate aqueous solution pre-cooled to 0-5°C, stir rapidly for 50s, and then stand for reaction in an ice-water bath for 12h. After the reaction, filter under reduced pressure; use ethanol, washing the product with water until the filtrate is neutral, and drying the washed product in a vacuum oven at 50°C...

Embodiment 2

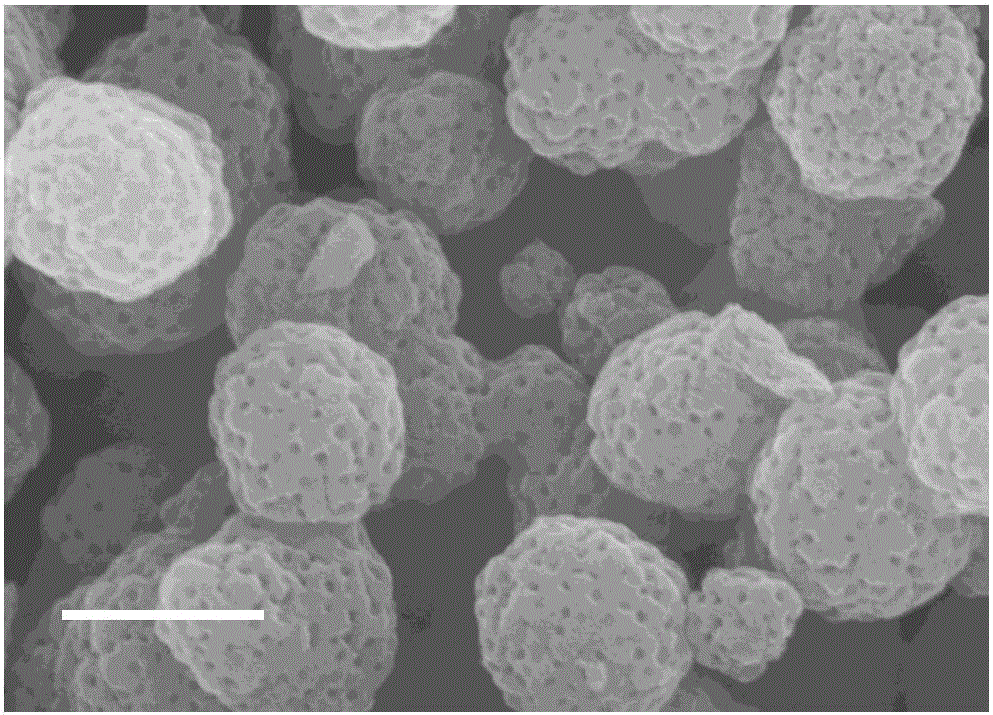

[0084] The embodiment of the present invention provides a method for preparing mesoporous carbon nanospheres with ultra-high specific surface area, comprising the following steps:

[0085] (1) Dissolve 0.17ml of aniline and 0.13ml of pyrrole in 12ml of ethanol / water mixed solvent (the volume ratio of ethanol and water is 1:2) to form solution 1; 30mg of PEO 113 -b-PS 445 Dissolve in 4ml tetrahydrofuran to form solution 2, then add solution 1 to solution 2 to self-assemble to obtain a light blue emulsion; after magnetic stirring for 0.5h, then ultrasonically disperse for 0.5h, then place in an ice-water bath and continue stirring for 0.5h , then, add 2ml of 0.41g / ml ammonium persulfate aqueous solution pre-cooled to 0-5°C, stir rapidly for 50s, and then stand for reaction in an ice-water bath for 12h. After the reaction, filter under reduced pressure; use ethanol, Washing the product with water until the filtrate is neutral, and drying the washed product in a vacuum oven at 50...

Embodiment 3

[0088] The embodiment of the present invention provides a method for preparing mesoporous carbon nanospheres with ultra-high specific surface area, comprising the following steps:

[0089] (1) Dissolve 0.17ml of aniline and 0.13ml of pyrrole in 12ml of ethanol / water mixed solvent (the volume ratio of ethanol and water is 1:2) to form solution 1; 30mg of PEO 113 -b-PS 445 Dissolve in 4ml tetrahydrofuran to form solution 2, then add solution 1 to solution 2 to self-assemble to obtain a light blue emulsion; after magnetic stirring for 0.5h, then ultrasonically disperse for 0.5h, then place in an ice-water bath and continue stirring for 0.5h , then, add 2ml of 0.41g / ml ammonium persulfate aqueous solution pre-cooled to 0-5°C, stir rapidly for 50s, and then stand for reaction in an ice-water bath for 12h. After the reaction, filter under reduced pressure; use ethanol, Wash the product with water until the filtrate is neutral, and dry the washed product in a vacuum oven at 50°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com