Method for preparing g-C3N4/MoS2 nanocomposite with vulcanizing sintering method

A nano-composite material and sintering technology, which is applied in the field of preparing g-C3N4/MoS2 nano-composite materials, can solve the problems of complicated heterojunction process, low yield, inability to produce and apply, etc. The effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mixing: Weigh 30 g of thiourea and 0.5 g of molybdenum trioxide, put the two in a ball mill jar and pass through an inert gas nitrogen ball mill for 10 hours to make them fully mixed and refine the particles to obtain off-white powder.

[0022] (2) Sintering: put the off-white powder obtained in step (1) in a corundum crucible with a lid, place it in a tube furnace with argon, raise the temperature to 600°C at a heating rate of 5°C / min, and keep it warm for 2h , naturally cooled to room temperature to obtain gray-black powder, which is g-C 3 N 4 / MoS 2 nanocomposites.

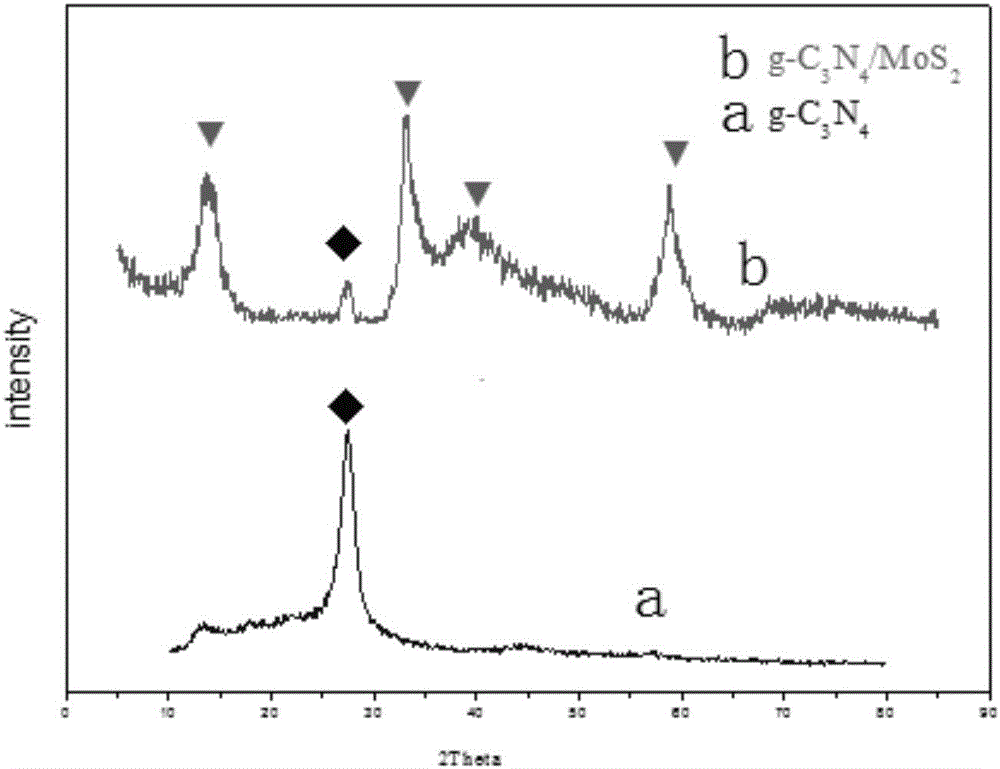

[0023] like figure 1 The X-ray diffraction pattern shown, where g-C 3 N 4 The characteristic peaks of the complex are in good agreement with the corresponding positions in the complex, and there are no other miscellaneous peaks, which proves that the g-C prepared by this method 3 N 4 / MoS 2 The nanoheterojunction has a very high purity.

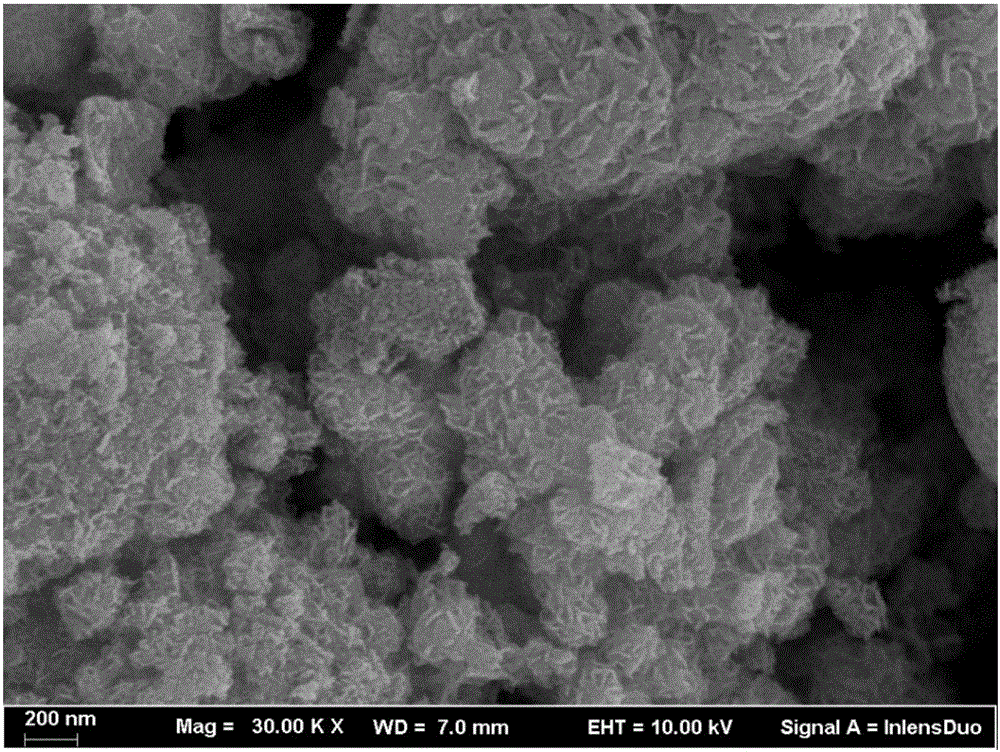

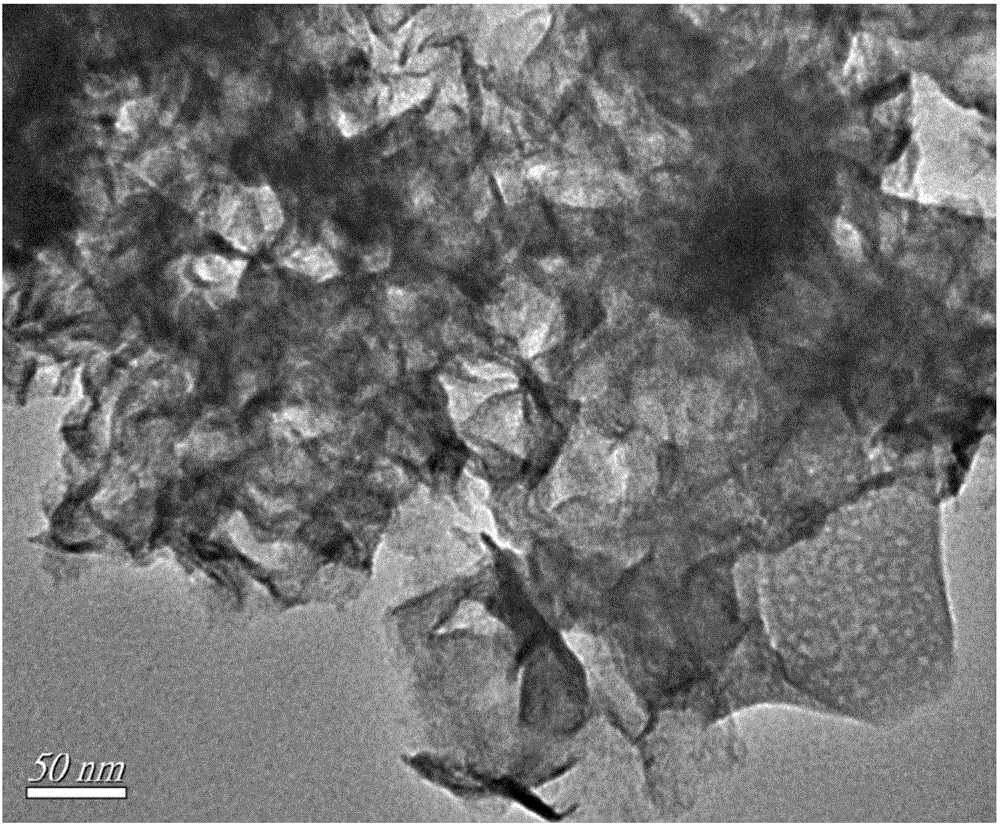

[0024] like figure 2 As shown, the g-C prepared by ...

Embodiment 2

[0027] (1) Mixing: Weigh 30 g of thiourea and 0.5 g of molybdenum trioxide, put the two in a ball mill jar and pass through an inert gas nitrogen ball mill for 10 hours to make them fully mixed and refine the particles to obtain off-white powder.

[0028] (2) Sintering: put the off-white powder obtained in step (1) in a corundum crucible with a lid, place it in a tube furnace with argon, raise the temperature to 650°C at a heating rate of 5°C / min, and keep it warm for 2h , naturally cooled to room temperature to obtain gray-black powder, which is g-C 3 N 4 / MoS 2 nanocomposites.

Embodiment 3

[0030] (1) Mixing: Weigh 30 g of thiourea and 0.5 g of molybdenum trioxide, put the two in a ball mill jar and pass through an inert gas nitrogen ball mill for 10 hours to make them fully mixed and refine the particles to obtain off-white powder.

[0031](2) Sintering: put the off-white powder obtained in step (1) in a corundum crucible with a lid, place it in a tube furnace with argon, raise the temperature to 550°C at a heating rate of 5°C / min, and keep it warm for 2h , naturally cooled to room temperature to obtain gray-black powder, which is g-C 3 N 4 / MoS 2 nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com