Comprehensive utilization method for coal chemical industry gasified black water high-temperature flashing steam

A technology of high-temperature flash steam and coal chemical industry, applied in chemical instruments and methods, separation methods, degassed water/sewage treatment, etc., can solve problems such as unbearable waste boiler system and rising gray water heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

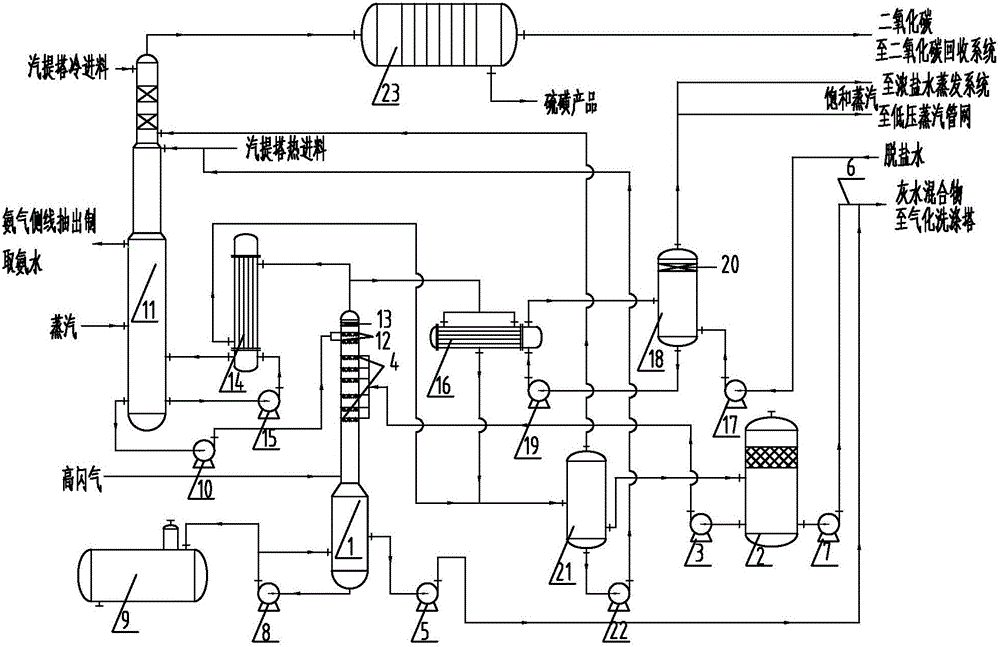

[0017] A method for comprehensive utilization of high-temperature flash steam of coal chemical gasification black water, which is characterized by comprising the following steps:

[0018] A. After gasification and washing black water at 230-260℃, after decompression to absolute pressure of 0.8-1.1Mpa, the high-temperature flash gas with absolute pressure of 0.8-1.1MPa and temperature of 170-184℃ produced by flash evaporation is referred to as high flash gas (By mass percentage, water vapor accounts for 98-98.6%, carbon dioxide accounts for 0.88-1.25%, ammonia accounts for 0.03-0.43%, carbon monoxide accounts for 0.45-0.64%, hydrogen sulfide accounts for 0.006-0.009%, and other gases account for 0.0065- 0.0093%), the residual pressure directly enters the tower from the lower part of the middle section of the combined purification tower (1), and the gasification deaerator (2) discharges part of the gray-water mixture, the temperature is 105-127 ° C, the absolute pressure is 0.12-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com