Method for converting farm wastes and monosodium glutamate wastewater into liquid compound fertilizer

A monosodium glutamate waste liquid and compound fertilizer technology, which is applied to the preparation of liquid fertilizers, fertilizers made from biological waste, and organic fertilizers. Effects of increasing germination rate and plant height, stabilizing properties, reducing pH value and salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

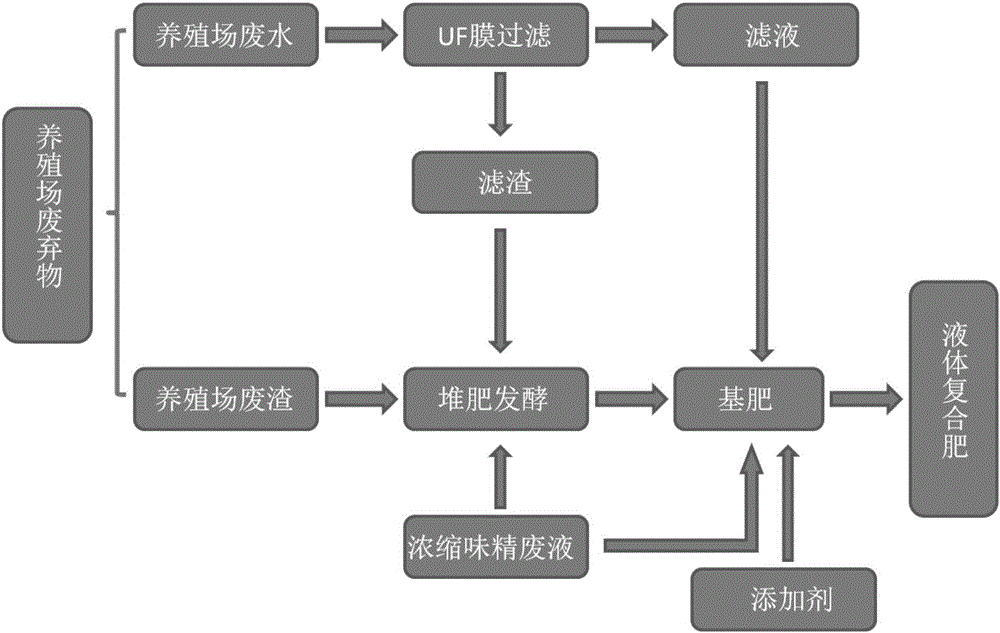

[0027] Such as figure 1 Shown, the invention provides the preparation method of liquid compound fertilizer, comprises the steps:

[0028] S1: Separating the farm waste by gravity sedimentation to obtain waste water and waste residue; the water content of the waste residue is 20% to 60%.

[0029] S2: Filtrate the waste water to obtain filtrate and filter residue; the moisture content of the filter residue is 20%-55%; the filtration is performed by ultrafiltration membrane, and the pore size of the ultrafiltration membrane is 0.001 μm-0.02 μm.

[0030] S3: Mix waste residue and filter residue evenly to obtain compost material, and carry out composting fermentation on compost material to obtain base manure; the mass ratio of waste residue and filter residue is (8~3):2; compost fermentation includes: adjusting the moisture content in the compost material to 58% to 62%, and then stacked to grow to 1.8m to 2m, 1.5m to 2m wide, and 0.6m to 1.5m high. Membrane, after 5 to 7 days of ...

Embodiment 1

[0034] S1: The waste from the farm is separated by gravity sedimentation in the sedimentation tank to obtain waste water and waste residue; the moisture content of the waste residue is 35%.

[0035] S2: Filter the waste water with an ultrafiltration membrane with a pore size of 0.01 μm to obtain a filtrate and a filter residue; the moisture content of the filter residue is 50%.

[0036] S3: Mix the waste residue with a moisture content of 35% and the filter residue with a moisture content of 50% in a ratio of 8:2 to obtain a compost material, adjust the moisture content of the compost material to 60%, and then stack it to grow to 1.8m in width 1.5m in length and 1.2m in height in a strip-shaped fermented heap. Cover the outside of the fermented heap with 3 layers of expanded polytetrafluoroethylene membranes for composting and fermentation. After 5 days of stacking, add MSG waste liquid to the fermented heap. Continue to stack until the total number of days is 15 days to obtai...

Embodiment 2

[0039] S1: The waste from the farm is separated by gravity sedimentation in the sedimentation tank to obtain waste water and waste residue; the moisture content of the waste residue is 40%.

[0040] S2: Filter the waste water with an ultrafiltration membrane with a pore size of 0.02 μm to obtain a filtrate and a filter residue; the moisture content of the filter residue is 50%.

[0041] S3: Mix the waste residue with a moisture content of 40% and the filter residue with a moisture content of 50% in a ratio of 8:2 to obtain a compost material, adjust the moisture content of the compost material to 61%, and then stack it to grow to 1.8m in width 1.7m in length and 1.2m in height in the form of piles of fermented products. Cover the outside of the pile with 3 layers of expanded polytetrafluoroethylene membranes for composting and fermentation. After 5 days of stacking, add MSG waste liquid to the pile of fermented Continue to stack until the total number of days is 13 days to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com