Microemulsion system and preparation method

A technology of microemulsion and reverse microemulsion, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of slowness, low plugging strength, and large dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

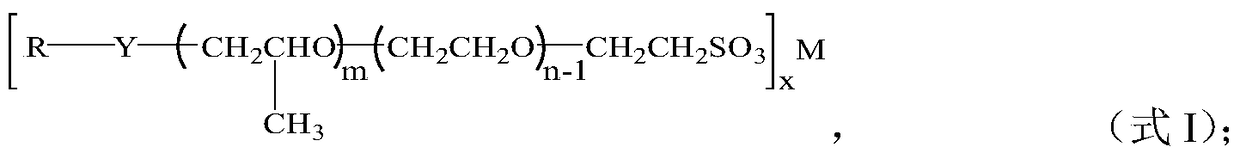

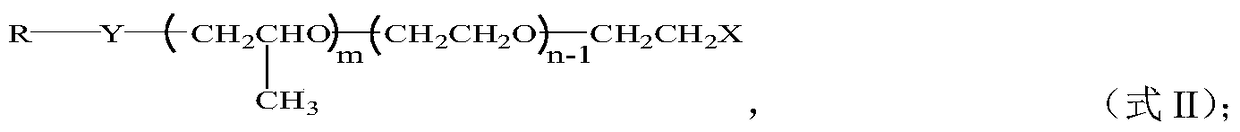

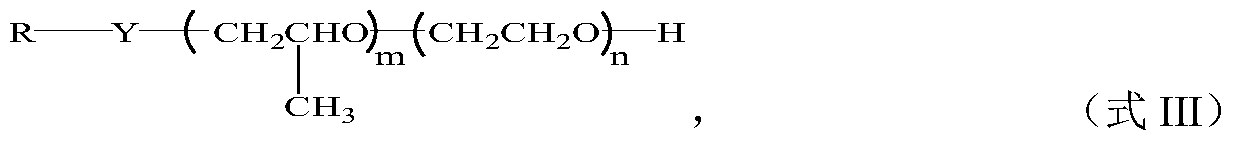

[0050] 1. Synthesis of sulfonate surfactants:

[0051] (1) Synthesis of chlorinated isomeric tetradecyl alcohol polyoxypropylene (10) polyoxyethylene (2) ether:

[0052] In a glass reactor equipped with a reflux condensing device, a thermometer, an agitator and a gas absorption device, add 92g of isomeric tetradecyl alcohol polyoxypropylene (10) polyoxyethylene (2) ether, 13g of pyridine, At a temperature of 68°C, slowly add 26.5g of thionyl chloride dropwise with a dropping funnel, stir while adding to make it evenly mixed, continue to react for 5.5 hours after the dropwise addition, end the reaction, let stand, cool and separate, use 30% sodium hydroxide solution to adjust the pH value of the upper layer to 7.4, then wash the upper layer three times with hot saturated brine, and dry to obtain chloroisomeric tetradecyl alcohol polyoxypropylene (10) polyoxyethylene (2) Ether, the yield is 87.9%.

[0053] (2) Synthesis of isomeric tetradecyl alcohol polyoxypropylene (10) poly...

Embodiment 2

[0059] The synthesis of the sulfonate surfactant and the preparation process of the microemulsion system are the same as in [Example 1], except that sodium acrylate is replaced by 2-acrylamido-2-methylpropanesulfonic acid. The initial particle size and distribution of the microspheres in the microemulsion system were tested using a Zetasizer Nano2000 particle size analyzer produced by Malvern Instruments in the United Kingdom; they were placed in brine with a total salinity of 160,000 mg / L at 92°C and anaerobic conditions for 7 days, 15 days, After 30 days and 45 days, the particle size of the microspheres was calculated, and the expansion factor of the microspheres was calculated; the TX-500 spinning drop interfacial tensiometer produced by the University of Texas was used to measure the relationship between the microemulsion system and the Pu 2-529 output oil. interfacial tension. The results are shown in Table 1.

Embodiment 3

[0061] The synthesis of sulfonate surfactant and the preparation process of microemulsion system are all the same as [Example 1], except that the emulsifying agent isomerized myristyl alcohol polyoxypropylene (10) polyoxyethylene (2) ether The dosages of potassium sulfonate and Tween 65 were changed to 3.6g and 13.9g, respectively. Use the Zetasizer Nano 2000 particle size analyzer produced by Malvern Instruments in the United Kingdom to test the initial particle size and distribution of microspheres in the microemulsion system; place it in brine with a total salinity of 160,000 mg / L at 92°C and anaerobic conditions for 7 days and 15 days , 30 days, and 45 days later, the particle diameter of the microspheres was calculated, and the expansion factor of the microspheres was calculated; the TX-500 spinning drop interfacial tensiometer produced by the University of Texas was used to measure the relationship between the microemulsion system and the Pu 2-529 output oil. interfacial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com