Biological preparation method of fermentation medium and rhamnolipid

A fermentation medium and biological preparation technology, applied in the field of efficient and harmless rhamnolipid biological preparation, can solve problems such as decreased expression of pathogenic factors, and achieve the effects of promoted secretion, increased production, and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

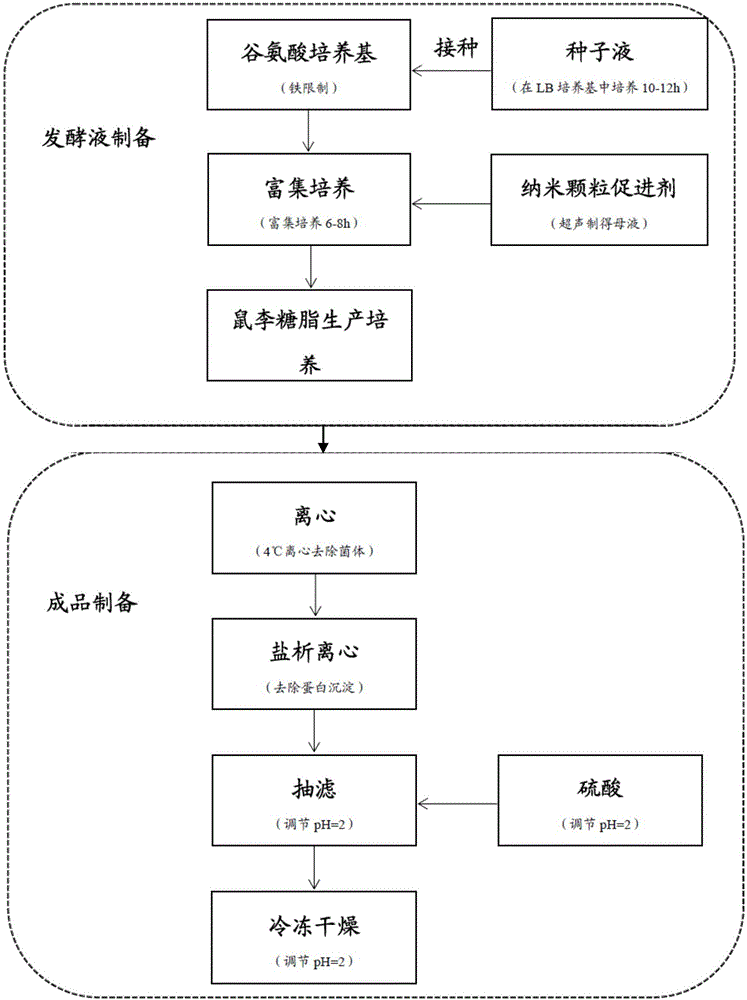

Method used

Image

Examples

Embodiment 1

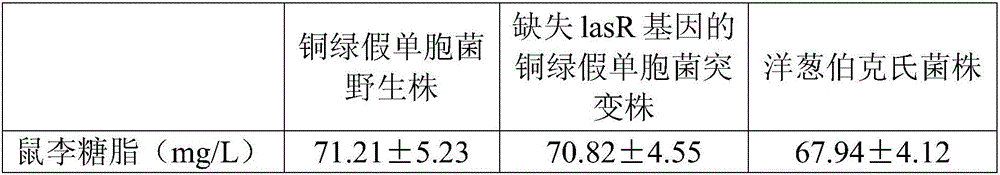

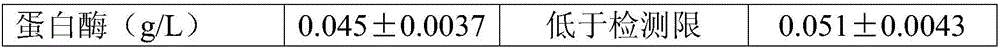

[0046] (1) Cultivate the seed solution for rhamnolipid synthesis for 10h-12h until it is in the logarithmic growth phase or the early stage of the stationary phase. The rhamnolipid producing bacteria used are: 1. Pseudomonas aeruginosa wild strain, 2. Pseudomonas aeruginosa mutant strain lacking lasR gene, 3. Burkholderia cepacia strain.

[0047] (2) prepare the iron-limited medium that promotes rhamnolipid production: c((NH 4 ) 2 SO 4 )=1g / L, c(KH 2 PO 4 )=1.7g / L, c(NaHPO 4 )=1.775g / L, c(EDTA)=0.0025g / L, c(ZnSO 4 ·7H 2 O)=0.011g / L, c(MnSO 4 ·H 2 O)=0.00154g / L, c(CuSO 4 ·5H 2 O)=0.000392g / L, c(Co(NO 3 ) 2 ·6H 2 O)=0.00025g / L, c(Na 2 B 4 o 7 10H 2 O)=0.000177g / L, c(CaCl 2 2H 2 O)=0.0667g / L, c(MgSO 4 )=0.289g / L, c((NH 4 ) 6 Mo 7 o 24 4H 2 O)=0.000185g / L, c(KOH)=0.146g / L, c(nitrilotriacetic acid)=0.2g / L, c(FeSO 4 ·7H 2 O)=0.000698g / L, c (glutamic acid)=10g / L.

[0048] (3) Insert (1) seed solution into (2) culture medium for fermentation and cultivation...

Embodiment 2

[0058] (1) Cultivate the seed solution for rhamnolipid synthesis. The used rhamnolipid producing bacteria is a mutant strain of Pseudomonas aeruginosa lacking the lasR gene. The seed solution was cultured to 1.2h in the early stage of logarithmic growth; 2.12h in the early stage of stationary stage; 3.20h in the late stage of stationary stage.

[0059] (2) prepare the iron-limited medium that promotes rhamnolipid production: c((NH 4 ) 2 SO 4 )=1g / L, c(KH 2 PO 4 )=1.7g / L, c(NaHPO 4 )=1.775g / L, c(EDTA)=0.0025g / L, c(ZnSO 4 ·7H 2 O)=0.011g / L, c(MnSO 4 ·H 2 O)=0.00154g / L, c(CuSO 4 ·5H 2 O)=0.000392g / L, c(Co(NO 3 ) 2 ·6H 2 O)=0.00025g / L, c(Na 2 B 4 o 7 10H 2 O)=0.000177g / L, c(CaCl 2 2H 2 O)=0.0667g / L, c(MgSO 4 )=0.289g / L, c((NH 4 ) 6 Mo 7 o 24 4H 2 O)=0.000185g / L, c(KOH)=0.146g / L, c(nitrilotriacetic acid)=0.2g / L, c(FeSO 4 ·7H 2 O)=0.000698g / L, c (glutamic acid)=10g / L.

[0060] (3) The seed solution of (1) is respectively inserted into the culture medium ...

Embodiment 3

[0069] (1) Cultivate the seed solution for rhamnolipid synthesis for 10h-12h until it is in the logarithmic growth phase or the early stage of the stationary phase. The used rhamnolipid producing bacteria is a mutant strain of Pseudomonas aeruginosa lacking the lasR gene.

[0070] (2) preparation promotes the substratum that rhamnolipid produces to be respectively: 1. ferric glutamate restriction substratum: c((NH4 ) 2 SO 4 )=1g / L, c(KH 2 PO 4 )=1.7g / L, c(NaHPO 4 )=1.775g / L, c(EDTA)=0.0025g / L, c(ZnSO 4 ·7H 2 O)=0.011g / L, c(MnSO 4 ·H 2 O)=0.00154g / L, c(CuSO 4 ·5H 2 O)=0.000392g / L, c(Co(NO 3 ) 2 ·6H 2 O)=0.00025g / L, c(Na 2 B 4 o 7 10H 2 O)=0.000177g / L, c(CaCl 2 2H 2 O)=0.0667g / L, c(MgSO 4 )=0.289g / L, c((NH 4 ) 6 Mo 7 o 24 4H 2 O)=0.000185g / L, c(KOH)=0.146g / L, c(nitrilotriacetic acid)=0.2g / L, c(FeSO 4 ·7H 2 (O)=0.000698g / L, c (glutamic acid)=10g / L; 2. casein iron-limited medium: c((NH 4 ) 2 SO 4 )=1g / L, c(KH 2 PO 4 )=1.7g / L, c(NaHPO 4 )=1.775g / L, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com