Semi-dry dedusting device and process for steelmaking converter flue gas with waste heat recovery

A waste heat recovery and steel-making converter technology, applied in the field of steel production, can solve the problems of consuming water resources, unable to directly return to the converter for use, and unable to recover the heat energy of the converter flue gas, and achieve the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

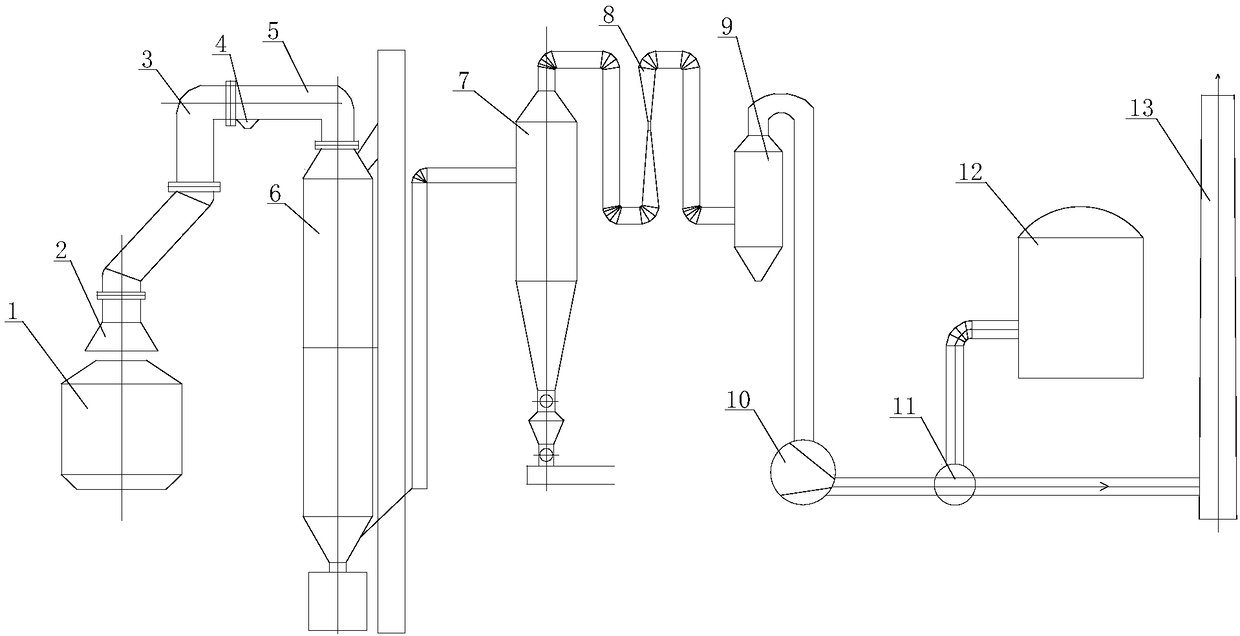

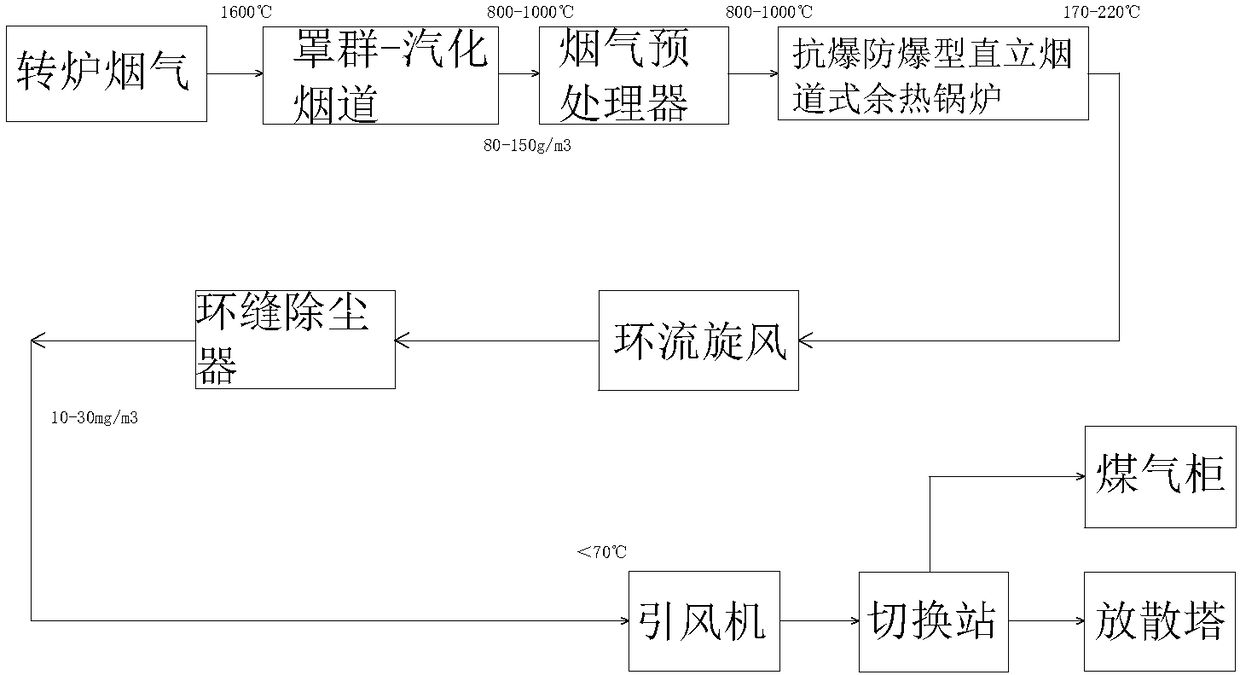

[0150] Take the 120t converter in a steel plant as an example:

[0151] The original dust removal process is the OG method, and the vaporization flue is equipped with one article, two articles, induced draft fan, and switching station. The technical transformation of the present invention adopts the CG (H) process. After the vaporization flue, the configuration is: → flue gas preprocessor → anti-riot and anti-riot type vertical flue waste heat boiler → circulating cyclone dust collector → annular seam dust collector → composite dehydration Device→*Induced Fan→*Switch Station...*is the original system process equipment.

[0152] [Related parameters of the new dust removal process]

[0153] --Anti-explosion-proof vertical flue waste heat boiler:

[0154] Flue gas volume: 90000Nm 3 / h

[0155] Inlet smoke temperature: 800~1000℃

[0156] Outlet smoke temperature: 170~220℃

[0157] Rated steam production: 28t

[0158] Rated pressure: 1~2mpa

[0159] Resistance loss: 1500~20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com