Preparation method for single-walled carbon nanotube (SWCNT) hollow ball oxygen reduction catalyst, and application of SWCNT hollow ball oxygen reduction catalyst

A technology of single-walled carbon nanotubes and carbon nanotubes, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as covering of catalytic active sites, easy agglomeration and long catalyst life, resource scarcity, etc., and achieve efficient oxygen reduction Electrochemical performance and stability, conducive to diffusion and rapid transport, and the effect of accelerating the kinetic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Preparation of monodisperse oxidized single-walled carbon nanotubes:

[0040] Add the initial single-walled carbon nanotube solid and potassium permanganate solid to the excess concentrated sulfuric acid solution at a ratio of 1: (1-4), and place the resulting reaction mixture in a water bath at 40-70°C Continue to stir and react for 1-6h. After diluting the reacted mixed solution with deionized water, add excess hydrogen peroxide solution and stir for more than 10min. Wash the water by high-speed centrifugation until the supernatant is neutral (PH=6-7), then remove the lower layer of solids and add deionized water to fully stir, and after further centrifugation, take a uniform and stable solution in the upper layer to obtain monodisperse oxidation Aqueous solutions of single-walled carbon nanotubes.

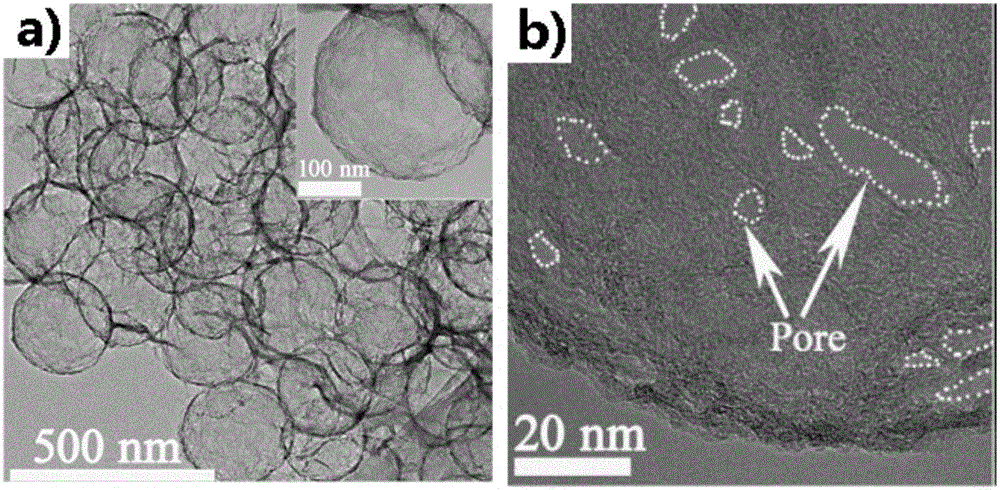

[0041] 2) Preparation of hollow spherical single-walled carbon nanotube assemblies:

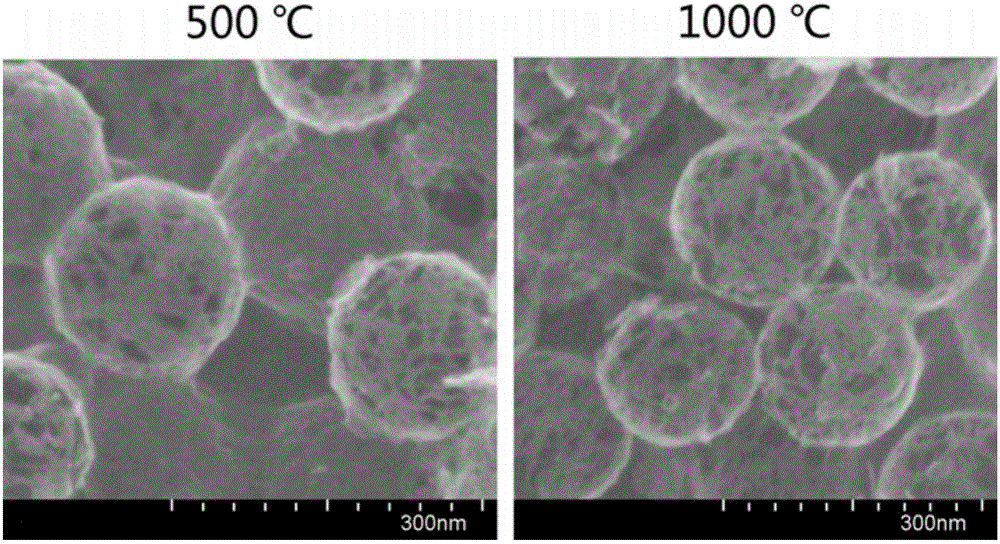

[0042] First, the silica microsphere template was dispersed in water by ultraso...

Embodiment 2

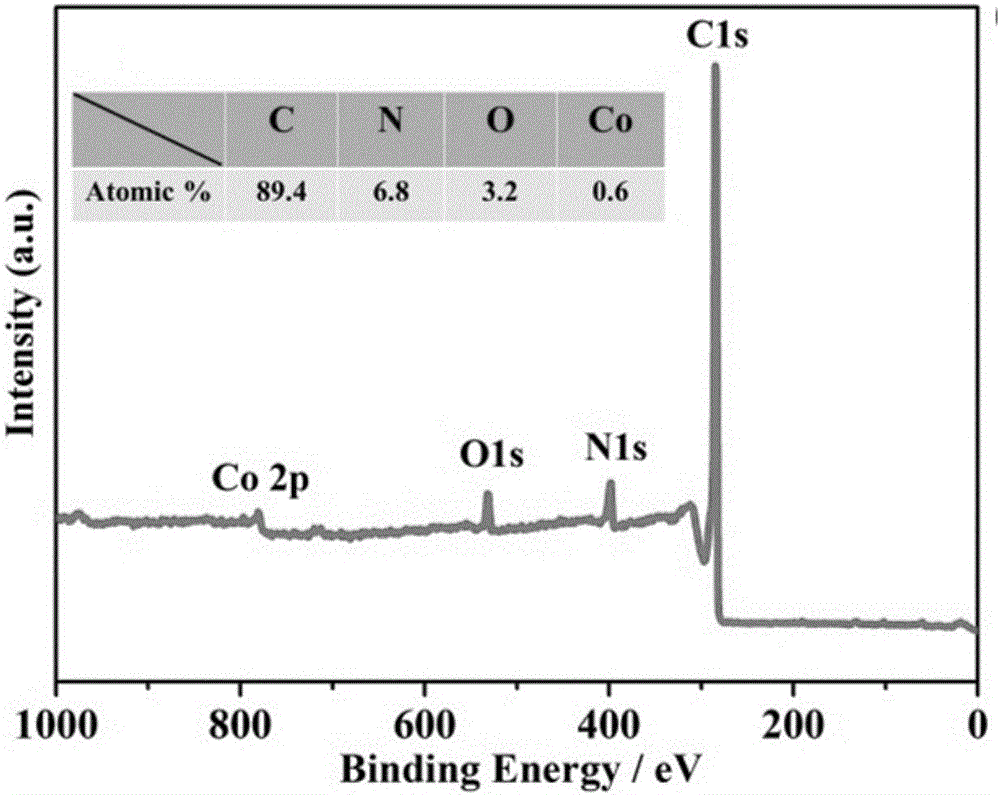

[0061] The Co-coordinated porphyrin-like ring compound vitamin B12 (VB12) and the hollow spherical single-walled carbon nanotube assembly were mixed uniformly by grinding with the assistance of ethanol at a mass ratio of 1:4 and 1:0.5, respectively. Annealed under a nitrogen atmosphere at 1000°C for 6 hours to obtain two cobalt / nitrogen co-doped single-wall carbon nanotube hollow sphere oxygen reduction catalysts, that is, single-wall carbon nanotube hollow sphere oxygen reduction catalysts

[0062] Figure 12 In this example, the cyclic voltammetry curve of the cobalt / nitrogen co-doped single-wall carbon nanotube hollow sphere oxygen reduction catalyst prepared by mixing VB12 and single-wall carbon nanotube spheres in a ratio of 1:4, at saturated N 2 Under the 0.1M KOH electrolyte solution, the cyclic voltammogram in the voltage range of -0.03 ~ 1.15V is similar to a rectangle, and there is no obvious reduction peak. while in saturated O 2 In the 0.1M KOH electrolyte soluti...

Embodiment 3

[0068] The Fe-coordinated porphyrin-like ring compound oxymethemin and the hollow spherical single-walled carbon nanotube assembly were uniformly mixed in a mass ratio of 1:0.5 with the assistance of ethanol, and the mixture was placed in a 1000°C Annealing for 1 h under an ammonia atmosphere yields an iron / nitrogen co-doped single-wall carbon nanotube hollow sphere oxygen reduction catalyst, that is, a single-wall carbon nanotube hollow sphere oxygen reduction catalyst.

[0069] Figure 16 It is the cyclic voltammetry curve of the iron / nitrogen co-doped single-walled carbon nanotube hollow sphere oxygen reduction catalyst obtained in this example, at saturated N 2 Under the 0.1M KOH electrolyte solution, the cyclic voltammogram in the voltage range of -0.03 ~ 1.15V is similar to a rectangle, and there is no obvious reduction peak. Relatively speaking, at saturation O 2 Under the 0.1M KOH electrolyte solution, there is an obvious characteristic peak of the oxygen reduction r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com