Compound premix for laying hens at laying stage used for formulating low-protein-content diet and application thereof

A compound premix, egg-laying technology, applied in application, animal feed, animal feed, etc., can solve the problems of increasing fecal ammonia nitrogen emission, increasing feed cost, amino acid waste, etc., to promote digestion and absorption, and regulate intestinal tract. The effect of bacterial flora balance and broad antibacterial spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment 1 preparation of composite premix

[0016] 1. Preparation of compound trace elements: Feed-grade trace element additive copper sulfate pentahydrate 0.45 grams, ferrous sulfate 2.4 grams, zinc sulfate heptahydrate 7.4 grams, manganese sulfate monohydrate 3.5 grams, potassium iodate 28 mg, selenous acid 7.5 milligrams of sodium and 11.215 grams of trace element carrier zeolite powder were mixed evenly to prepare a composite trace element premix for use.

[0017] 2. Preparation of compound vitamins: Feed-grade vitamin additive vitamin A acetate (500,000 IU / g): 300 mg, vitamin D3 (500,000 IU / g): 110 mg, vitamin E: 280 mg, vitamin K3: 25mg, Vitamin B1: 35mg, Vitamin B2: 110mg, Vitamin B6: 55mg, Vitamin B12: 0.3mg, Biotin: 1.7mg, Niacin: 420mg, Pantothenic Acid: 140mg, Folic Acid: 12mg , 3511 mg of vitamin carrier rice husk powder were mixed evenly to make a compound microecological preparation for use.

[0018] 3. Composite probiotics: The probiotics ar...

specific Embodiment approach 2

[0026] Specific embodiment 2 Preparation of complete diet

[0027] Use the premix prepared by the above method to prepare a complete feed, and the formula is as follows,

[0028] Full-price material formula example 1:

[0029] raw material name Formula ratio corn 65.5 soybean meal 21 stone powder 7.5 Premix formula example 1 6 total 100

[0030] Full-price material formula example 2:

[0031] raw material name Formula ratio corn 66 soybean meal 21 stone powder 8 Premix formulation example 2 6 total 100

[0032] Full-price material formula example 3:

[0033] raw material name Formula ratio corn 67 soybean meal 18 stone powder 9 Premix formulation example 3 6 total 100

[0034] Feeding test and verification:

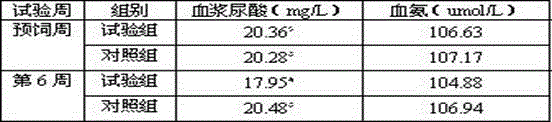

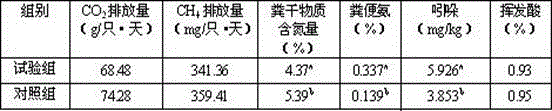

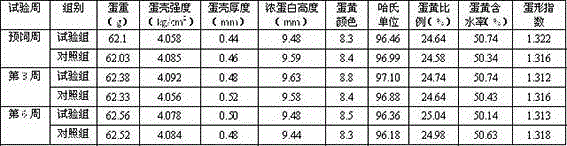

[0035] A comparative test was carried out between the feed of the full-price feed formula example 2 and the full-price diet prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com