A kind of preparation method of cefixime dry suspension granule

A technology of cefixime and dry suspension, applied in the field of medicine, can solve the problems of poor solubility and instability of cefixime preparations, and achieve the effects of improving stability and solubility, increasing acceptability, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to the above formula, the present invention also provides a preparation method of cefixime dry suspension granules, wherein, by weight percentage, comprising:

[0037] Step A, take 5-20% of cefixime, 1-10% of disintegrating agent, 30-70% of sweetener a and 1-10% of suspending agent which have been sieved and mix thoroughly, then add wetting agent to prepare The soft material is sieved and then dried to obtain the dry-suspended intermediate granules of cefixime.

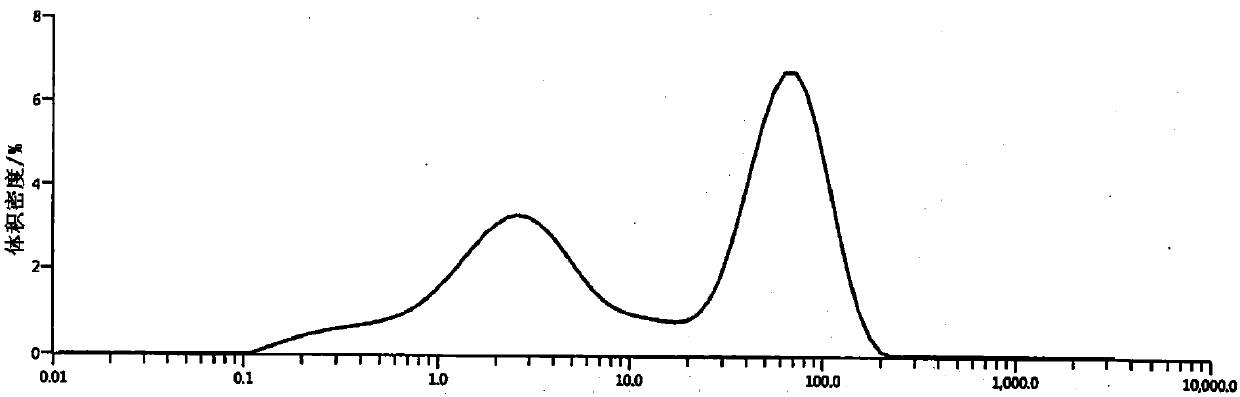

[0038] The particle size distribution figure of cefixime of the present invention is as follows figure 1 As shown, among them, Dv(10)100um. Among them, Dv (Volume Density) is the volume density.

[0039] Preferably, the disintegrant can be starch, pregelatinized starch, sodium carboxymethyl starch, hydroxypropyl starch, dextrin, cross-linked carmellose sodium, cross-linked carmellose calcium low-substituted One or more of hydroxypropyl cellulose, cross-linked polyvinylpyrrolidone, etc.

[0040] Pr...

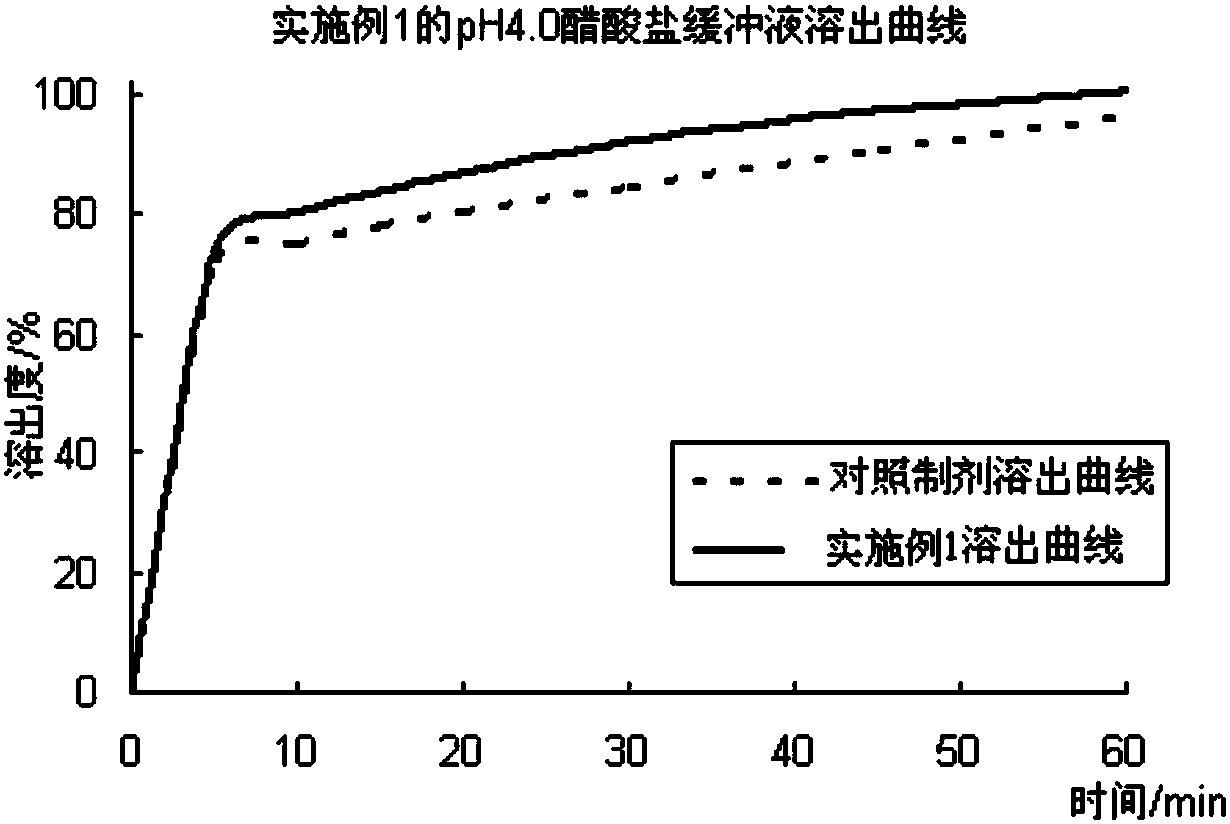

Embodiment 1

[0058] The preparation process is as follows:

[0059] Step 1: Under the condition of 23°C / 55%RH, take cefixime, disintegrating agent, sweetener a, and suspending agent to pass through 80-mesh sieve respectively, place them in a multi-directional mixer and mix for 15 minutes, add 50 % ethanol is used as a wetting agent, made into a soft material, passed through a 30-mesh sieve, and then dried in a fluidized bed at 50°C to obtain dry-suspended intermediate granules of cefixime; the second step is to take the sweetener b , coloring agent and hydroxypropyl methylcellulose are added in 50% ethanol solution, fully dissolved to obtain the auxiliary material solution, after adding a pH regulator to adjust the pH value to 3.0, slowly spray on the surface of the cefixime dry-suspended intermediate granules, After drying at 40°C, finally add a solubilizer and a flavoring agent and mix in a multi-directional mixer for 15 minutes to obtain dry suspension granules of cefixime. During the ...

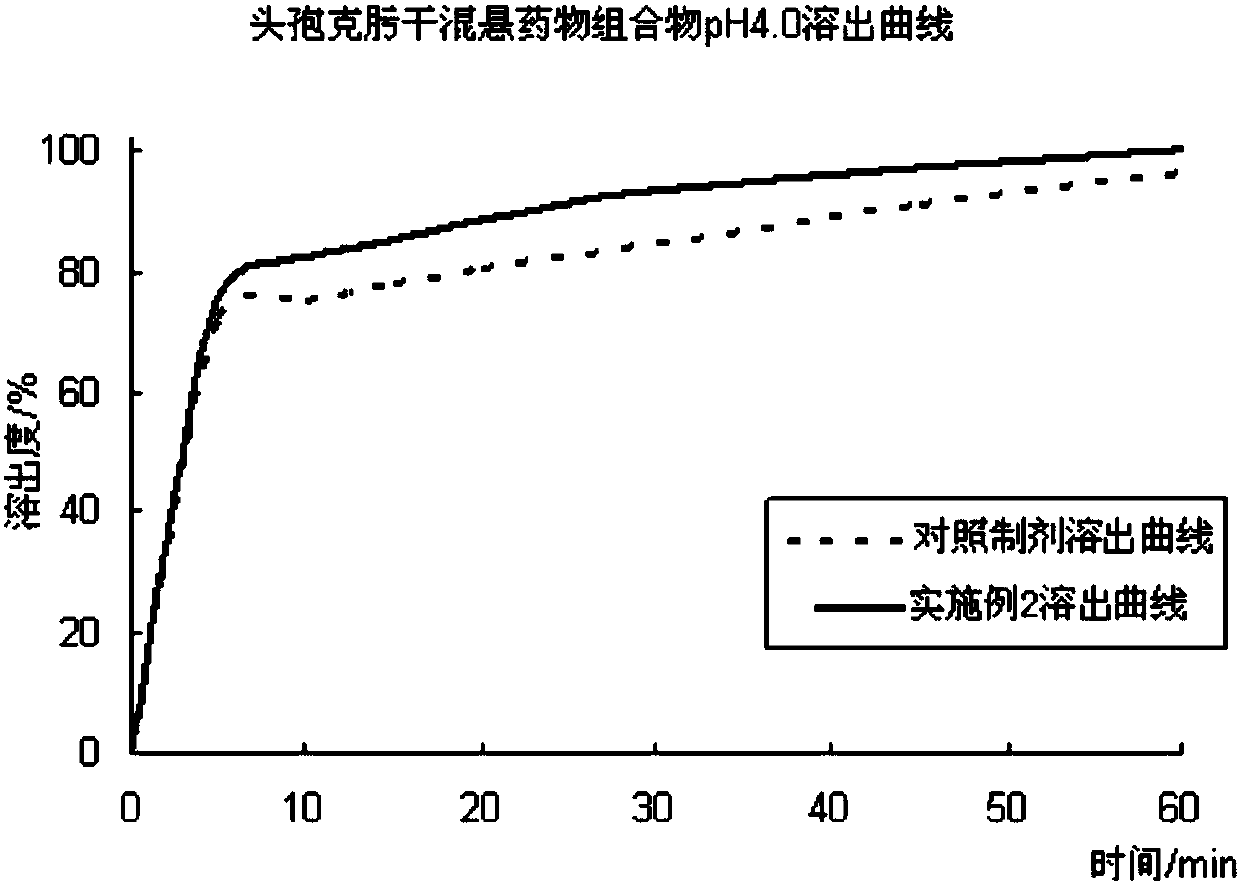

Embodiment 2

[0069] The preparation process is as follows:

[0070] Step 1: Under the condition of 22°C / 60%RH, take cefixime, disintegrant, sweetener a, and suspending agent to pass through 80-mesh sieve respectively, place them in a multi-directional mixer and mix for 25 minutes, add 50 % ethanol is used as a wetting agent, made into a soft material, passed through a 30-mesh sieve, and then dried in a fluidized bed at 45°C to obtain dry-suspended intermediate granules of cefixime; the second step is to take the sweetener b , coloring agent and hydroxypropyl methylcellulose are added in 30% ethanol solution, and after fully dissolving, adjuvant solution is obtained, after adding pH adjuster to adjust the pH value to 3.5, slowly spray on the surface of cefixime dry-suspended intermediate granules, after Dry at 40°C, and finally add a solubilizer and a flavoring agent and mix in a multi-directional mixer for 20 minutes to obtain dry suspension granules of cefixime. During the preparation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com