Method for preparing multi-element co-doped graphene by hydrothermal method

A technology of co-doping and hydrothermal method, applied in the direction of graphene, chemical instruments and methods, electrical components, etc., to achieve the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

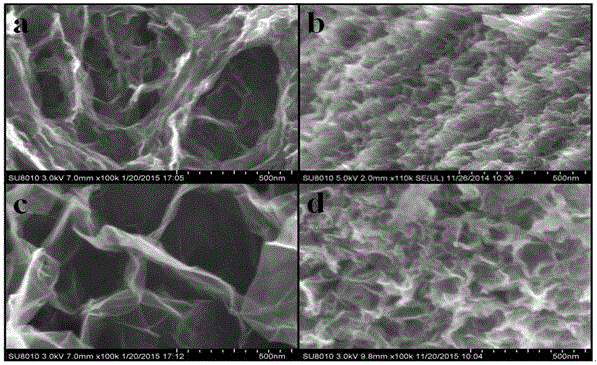

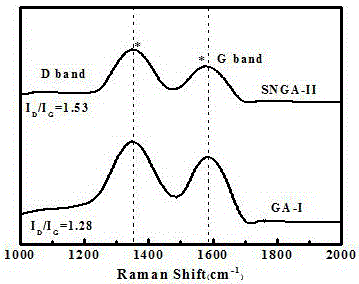

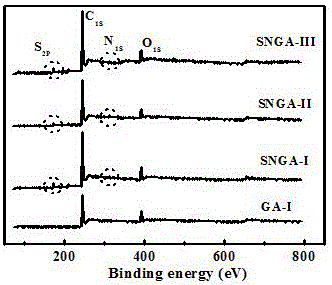

Image

Examples

Embodiment 1

[0049] The first example: (1) The first step is to improve the Hummers method to prepare graphite oxide: 1. Weigh 0.1g graphite powder and 0.05g NaNO respectively 3 Mix evenly; 2. Under the condition of ice-water bath, add 3mL concentrated H 2 SO 4 Stir well, and slowly add 0.5g KMnO 4 Stir for 0.5 hours; 3. After stirring for 1 day at room temperature, add 10 mL of 1% H 2 SO 4 Stir for 0.5 hours; 4. Add an appropriate amount (about 0.5mL) of hydrogen peroxide (H 2 o 2 ) Stir until no bubbles appear in the solution; 5. Clean, use 5% HNO in a 4000mL beaker 3 Wash 2 times, then use 1% HNO 3 Wash twice; 6. Add deionized water and centrifugally wash to pH = 7, and dry the resulting solution at room temperature 25° C. to obtain graphite oxide.

[0050] The second example: (1) The first step is to improve the Hummers method to prepare graphite oxide: 1. Weigh 3g of graphite powder and 2.5g of NaNO 3 Mix evenly; 2. Under the condition of ice-water bath, add 50mL concentrated ...

Embodiment 2

[0053] Weigh 0.004g of graphite oxide to prepare 45mL of graphene oxide dispersion, weigh 0.004g of thiourea and 0.004g of ammonium hydrogen phosphate, mix and stir until completely dissolved, put the obtained solution into a 50mL hydrothermal reaction kettle, and adjust the temperature Keep at 150°C for 1 hour. After the hydrothermal reactor is cooled to room temperature, take out the reaction product and wash it with deionized water. The product is frozen for 12 hours and then dried in a vacuum freeze dryer for 24 hours to obtain phosphorus, nitrogen and sulfur multi-component doped graphene. product.

Embodiment 3

[0055] Weigh 0.14g of graphite oxide to prepare 45mL of graphene oxide dispersion, weigh 4.2g of thiourea and 4.2g of ammonium hydrogen phosphate, mix and stir until completely dissolved, put the obtained solution into a 50mL hydrothermal reaction kettle, and adjust the temperature Keep at 180°C for 24 hours. After the hydrothermal reactor is cooled to room temperature, take out the reaction product and wash it with deionized water. The product is frozen for 1 hour and then dried in a vacuum freeze dryer for 24 hours to obtain phosphorus, nitrogen and sulfur multi-component doped graphene. product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com