Industrial wastewater treatment technology

A technology for treating process and industrial wastewater, applied in multi-stage water treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of increasing operation difficulty and cost, low sludge and organic pollutant removal efficiency, etc. problems, to achieve the effect of improving the quality of effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

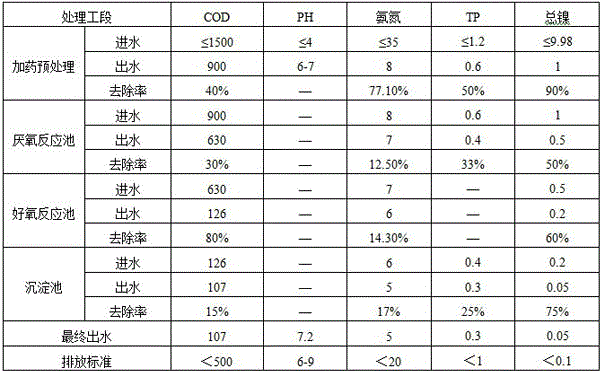

[0064] The wastewater produced by a chemical company needs to be treated, the treatment capacity is 24 tons / day, the influent concentration before treatment is COD≤1500mg / L, PH≤4, ammonia nitrogen≤35mg / L, TP≤1.2mg / L, characteristic pollutants : Total nickel≤9.98mg / L. According to customer needs, effluent water quality requirements: COD<500mg / L, PH: 6-9, ammonia nitrogen<20mg / L, TP<1mg / L, characteristic pollutants: total nickel<0.1mg / L.

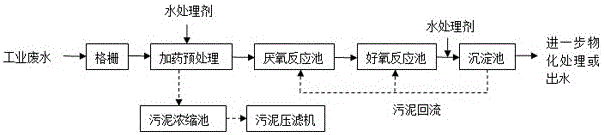

[0065] Combined with the above combined process, according to the quality of the wastewater, there is no large amount of suspended solids in the wastewater, so the screen can be used instead of the grid, and the addition of lye is added in the pretreatment process to neutralize the acidity of the wastewater. process such as figure 1 shown.

[0066] The process includes the following steps:

[0067] (1) Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com