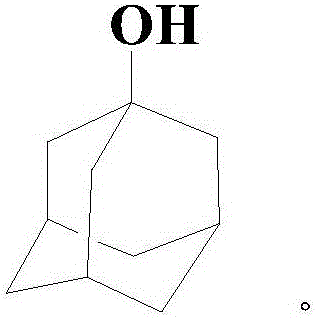

Preparation method of 1-adamantanol

A technology of adamantanol and adamantane, which is applied in the field of preparation of 1-adamantanol, can solve the problems of high safety risk, poor selectivity, and high cost, and achieve the effects of small safety risk, simple operation, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

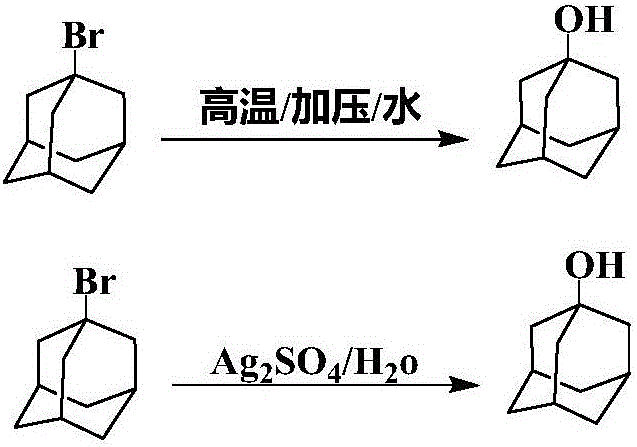

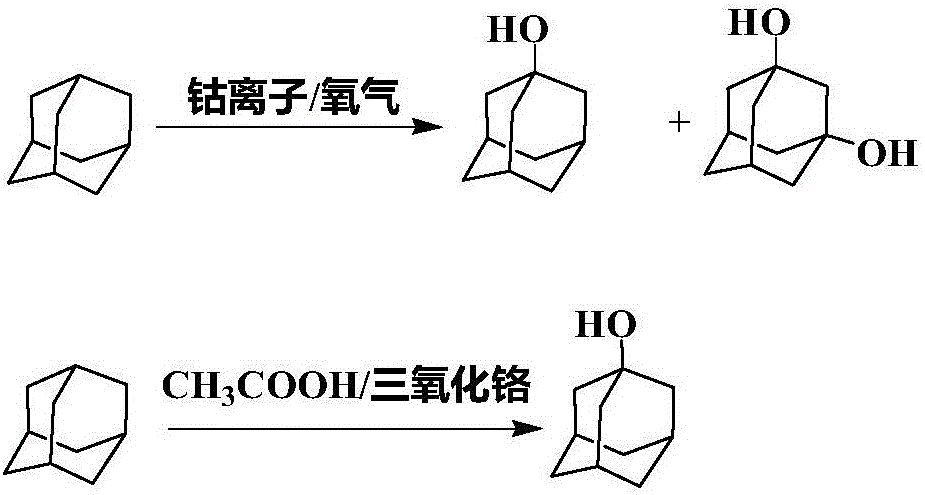

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the 1-adamantanol of the present embodiment, comprises the steps:

[0051] (1) At room temperature, add 400.0g (2.94mol) of adamantane to a mixed system of 517.6g (3.24mol) of bromine and 20.0g of water in a 2L three-necked flask, and the white adamantane solid gradually dissolves after bromine is added , the system is quickly filled with brown-red gas, and a reflux condenser is installed (low-temperature ethanol is used as the cooling medium), and the temperature rises slowly in stages for reaction, followed by three temperature stages of heat preservation reaction, every 3 hours is a stage, the first stage is 40 ° C, the second stage The stage is 70°C, and the third stage is 120°C. Sampling GC test shows that the remaining adamantane is less than 2.5%, stop the reaction, and react to generate 1-bromoadamantane to obtain a mixed system containing 1-bromoadamantane.

[0052] (2) The mixed system containing 1-bromoadamantane prepared in step (1)...

Embodiment 2

[0055] The preparation method of the 1-adamantanol of the present embodiment, comprises the steps:

[0056](1) At room temperature, add 400.0g (2.94mol) of adamantane to a mixed system of 720.0g (4.51mol) of bromine and 40.0g of water in a 2L three-necked flask at room temperature. After adding bromine, the white adamantane solid gradually dissolves , the system is quickly filled with brown-red gas, a reflux condenser is installed (low-temperature ethanol is used as the cooling medium), and the temperature rises slowly in stages. The reaction is followed by three temperature stages of heat preservation and reaction. Every 3 hours is a stage, the first stage is 50 ° C, the second stage The stage is 80°C, and the third stage is 110°C. Sampling GC test shows that the remaining adamantane is less than 2.5%, stop the reaction, and react to generate 1-bromoadamantane to obtain a mixed system containing 1-bromoadamantane.

[0057] (2) The mixed system containing 1-bromoadamantane pre...

Embodiment 3

[0060] The preparation method of the 1-adamantanol of the present embodiment, comprises the steps:

[0061] (1) At room temperature, add 400.0g (2.94mol) of adamantane to a mixed system of 894.1g (5.61mol) of bromine and 120.0g of water in a 2L three-necked flask, and the white adamantane solid gradually dissolves after bromine is added , the system is quickly filled with brown-red gas, and a reflux condenser is installed (low-temperature ethanol is used as the cooling medium). The stage is 90°C, and the third stage is 120°C. Sampling GC test shows that the remaining adamantane is less than 2.5%, stop the reaction, react to generate 1-bromoadamantane, and obtain a mixed system containing 1-bromoadamantane.

[0062] (2) The mixed system containing 1-bromoadamantane prepared in step (1) was distilled at 30-60°C to remove excess bromine, and when the bromine-free steam evaporated, stop the distillation and control the temperature of the mixed system When the temperature is 30-80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com