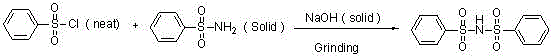

Method for preparing dibenzenesulfonimide by solvent-free grinding method

A technology of bisbenzenesulfonyl imide and benzenesulfonamide, which is applied in the field of preparation of bisbenzenesulfonyl imide, can solve the problems of easy hydrolysis of benzenesulfonyl chloride, environmental pollution, and large amount of benzenesulfonamide, and achieve atom utilization High, reduce production costs, reduce pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

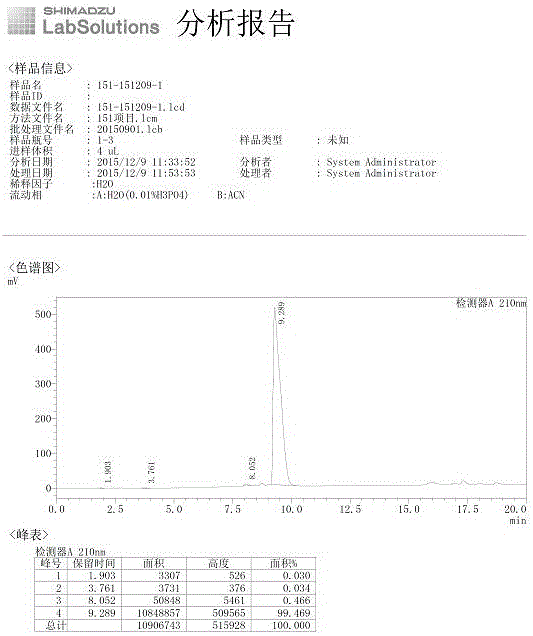

Image

Examples

Embodiment 1

[0022] Example 1 A method for preparing bis-benzenesulfonyl imide by solvent-free grinding method, first put 500 grams (3.185 mol) of benzenesulfonamide and 589 grams (3.344 mol) of pure benzenesulfonyl chloride into a stainless steel with a volume of 5 liters Grind in a ball mill for 5 minutes to fully mix benzenesulfonamide and benzenesulfonyl chloride at room temperature; then put 140 grams (3.5 mol) of solid NaOH into the stainless steel ball mill in 5 times, and grind the material for 3~7 hours after each addition of NaOH Minutes, and keep the temperature of the reactant below 60°C, continue to grind for 15 minutes; after the reaction, move the reactant from the ball mill to a 5-liter three-necked bottle, add methanol 10 times its mass to the reactant, Put on the condenser, heat, stir, and reflux for 30 minutes, heat filter, wash the solid in the funnel three times with hot methanol, filter to remove the generated NaCl, and combine the filtrate; After removing 2 / 3 of the ...

Embodiment 2

[0027] Example 2 A method for preparing bis-benzenesulfonyl imide by solvent-free grinding method, first put 500 grams (3.185 mol) of benzenesulfonamide and 563 grams (3.185 mol) of pure benzenesulfonyl chloride into a stainless steel with a volume of 5 liters Grind in a ball mill for 5 minutes to fully mix benzenesulfonamide and benzenesulfonyl chloride at room temperature; then put 127 grams (3.185 mol) of solid NaOH into the stainless steel ball mill in 5 times, and grind the material for 3~7 hours after each addition of NaOH Minutes, and keep the temperature of the reactant below 60°C, continue to grind for 15 minutes; after the reaction, move the reactant from the ball mill to a 5-liter three-necked bottle, add methanol 3 times its mass in the reactant, pack Put on the condenser, heat, stir, and reflux for 30 minutes, heat filter, wash the solid in the funnel three times with hot methanol, filter to remove the generated NaCl, and combine the filtrate; After 2 / 3 of the sol...

Embodiment 3

[0028] Example 3 A method for preparing bis-benzenesulfonyl imide by solvent-free grinding method, first put 500 grams (3.185 mol) of benzenesulfonamide and 729 grams (4.14 mol) of pure benzenesulfonyl chloride into a stainless steel with a volume of 5 liters Grind in a ball mill for 5 minutes to fully mix benzenesulfonamide and benzenesulfonyl chloride at room temperature; then put 171 grams (4.3 mol) of solid NaOH into the stainless steel ball mill in 5 times, and grind the material for 3~7 hours after adding NaOH each time. Minutes, and keep the temperature of the reactant below 60°C, continue to grind for 15 minutes; after the reaction, move the reactant from the ball mill to a 5-liter three-necked bottle, add methanol 5 times its mass to the reactant, Put on the condenser, heat, stir, and reflux for 30 minutes, heat filter, wash the solid in the funnel three times with hot methanol, filter to remove the generated NaCl, and combine the filtrate; After 2 / 3 of the solvent wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com