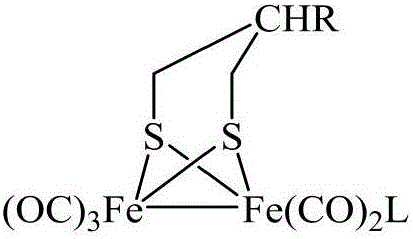

Fe-Fe hydrogenase model containing functionalized phosphine ligand and preparation method thereof

A technology of iron hydrogenase and phosphine ligand, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, iron organic compounds, etc., to achieve mild conditions, excellent catalytic hydrogen production capacity, and easy availability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

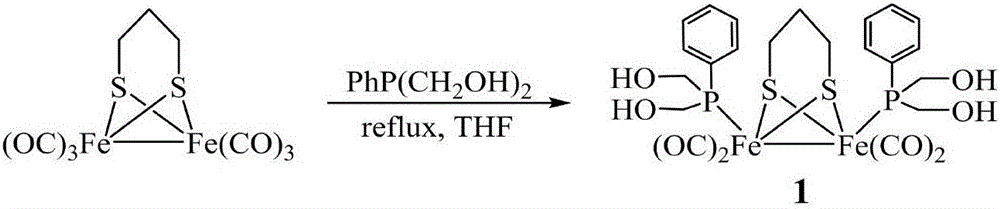

Embodiment 1

[0022] A method for preparing a model substance 1 of iron-iron hydrogenase containing a functionalized phosphine ligand, the chemical formula of the model substance 1 is [{(μ-SCH 2 ) 2 CH 2} Fe 2 (CO) 4 ][PhP(CH 2 Oh) 2 ] 2 , the preparation process is as follows:

[0023]

[0024] Concrete preparation steps are as follows:

[0025] 1) Under nitrogen protection, add 386 mg (1.0 mmol) [(μ-SCH 2 ) 2 CH 2 ] Fe 2 (CO) 6 and 30mL tetrahydrofuran to obtain a reddish-brown solution;

[0026] 2) At room temperature and under nitrogen protection, 408mg (2.4mmol) PhP(CH 2 Oh) 2 The thick substance was directly added dropwise into the reddish-brown solution, and heated to reflux for 30 hours to obtain a black-red solution, and the raw material point basically disappeared as monitored by TLC;

[0027] 3) Dry the solvent under reduced pressure, extract the residue with EtOAc, use petroleum ether / EtOAc=1:1 (v / v) as a developing solvent for thin-layer chromatography separat...

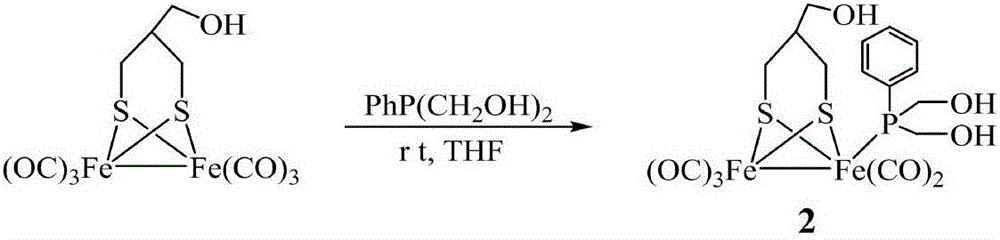

Embodiment 2

[0030] A preparation method of a model substance 2 of iron-iron hydrogenase containing a functionalized phosphine ligand, the chemical formula of the model substance 2 is [{(μ-SCH 2 ) 2 CHCH 2 OH}Fe 2 (CO) 5 ][PhP(CH 2 Oh) 2 ], the preparation process is as follows:

[0031]

[0032] Concrete preparation steps are as follows:

[0033] 1) Under nitrogen protection, add 374 mg (0.9 mmol) [(μ-SCH 2 ) 2 CHCH 2 OH]Fe 2 (CO) 6 and 15mL tetrahydrofuran to obtain a red solution;

[0034] 2) At room temperature and under nitrogen protection, 170mg (1.0mmol) PhP(CH 2 Oh) 2 The thick substance was directly added dropwise to the red solution, and stirred overnight at room temperature to obtain a reddish-brown solution. TLC monitoring showed that a new red spot appeared and a small amount of raw material red spots existed;

[0035] 3) Dry the solvent under reduced pressure, extract the residue with EtOAc, use petroleum ether / EtOAc=2:3 (v / v) as a developer for thin-layer ch...

Embodiment 3

[0038] A preparation method of a model substance 3 of iron-iron hydrogenase containing a functionalized phosphine ligand, the chemical formula of the model substance 3 is [{(μ-SCH 2 ) 2 CH 2} Fe 2 (CO) 5 ][PhP(CH 2 OH)(CH 2 CO 2 Me)], the preparation process is as follows:

[0039]

[0040] Concrete preparation steps are as follows:

[0041] 1) Under nitrogen protection, add 48mg (0.46mmol) CH 2 (CO 2 h) 2 , 68mg (0.56mmol) DMAP and 220mg (1.06mmol) DCC, put it in an ice-water bath down to 0 ° C, inject 20mL CH 2 Cl 2 ;

[0042] 2) After stirring at low temperature for 2 hours, add 243mg (0.46mmol) model substance [{(μ-SCH 2 ) 2 CH 2} Fe 2 (CO) 5 ][PhP(CH 2 Oh) 2 ], remove the ice-water bath and naturally rise to room temperature, continue to stir for 6h, and the TLC monitoring raw material point disappears substantially;

[0043] 3) dry the solvent under reduced pressure, use CH 2 Cl 2 Extract the residue with petroleum ether / CH 2 Cl 2 =2:3(v / v) was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com