Method for preparing large-particle monodispersed high-stable polymer emulsion by CO2 induced in-situ charge neutrality technology

A polymer emulsion and large particle size technology, applied in the field of emulsion polymerization, can solve the problems of long production cycle, high cost, complex production equipment, etc., and achieve the effects of reducing the number, enhancing particle stability, and improving surface potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

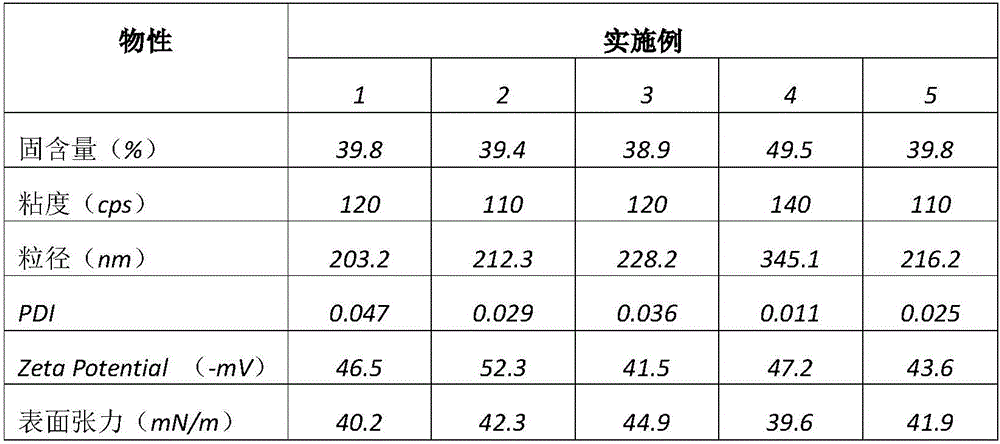

Examples

Embodiment 1

[0019] (1) In parts by mass, monomer styrene 40g, CO 2 Add 0.2g of diethylaminoethyl methacrylate monomer, 0.6g of emulsifier sodium lauryl sulfate, 0.2g of silicone defoamer polydimethylsiloxane, and 0.4g of reducing agent sodium sulfite into the reaction kettle , add 60 g of deionized water, and stir to completely dissolve the reactants;

[0020] (2) Pass CO into the above reaction system 2 Gas for 40min to make it CO 2 Form carbonic acid with water to ensure that the pH of the reaction system is less than 5, thereby promoting CO 2 Response to monomer salt formation. On the other hand, CO 2 The introduction of gas will remove the air in the reactor, so that the whole reaction is carried out under CO 2 carried out under gas protection.

[0021] (3) After raising the temperature to 45°C, 0.6 g of ammonium persulfate initiator was added to initiate the polymerization reaction. After the reaction was carried out for 1 hour, N 2 Replace CO in the system 2 Gas, maintain 4...

Embodiment 2

[0023] (1) In parts by mass, monomer styrene 40g, CO 2 The response monomer diethylaminoethyl methacrylate 0.4g, emulsifier sodium dodecylbenzene sulfonate 0.6g, silicone defoamer polydimethylsiloxane 0.2g, reducing agent sodium sulfite 0.4g were added to In the reaction kettle, add 60 g of deionized water, and stir to completely dissolve the reactant;

[0024] (2) Pass CO into the above reaction system 2 Gas for 40min to make it CO 2 Form carbonic acid with water to ensure that the pH of the reaction system is less than 5, thereby promoting CO 2 Response to monomer salt formation. On the other hand, CO 2 The introduction of gas will remove the air in the reactor, so that the whole reaction is carried out under CO 2 carried out under gas protection.

[0025] (3) After raising the temperature to 45°C, 0.6 g of ammonium persulfate initiator was added to initiate the polymerization reaction. When the reaction was carried out for 1.5 hours, N 2 Replace CO in the system 2 ...

Embodiment 3

[0027] (1) In parts by mass, monomer styrene 20g, methyl methacrylate 20g, CO 2 The response monomer diethylaminoethyl methacrylate 0.4g, emulsifier sodium dodecylbenzene sulfonate 0.6g, silicone defoamer polydimethylsiloxane 0.1g, reducing agent sodium sulfite 0.4g were added to In the reaction kettle, add 60 g of deionized water, and stir to completely dissolve the reactant;

[0028] (2) Pass CO into the above reaction system 2 Gas for 40min to make it CO 2 Form carbonic acid with water to ensure that the pH of the reaction system is less than 5, thereby promoting CO 2 Response to monomer salt formation. On the other hand, CO 2 The introduction of gas will remove the air in the reactor, so that the whole reaction is carried out under CO 2 carried out under gas protection.

[0029] (3) Add 0.6 g of ammonium persulfate as an initiator after raising the temperature to 45° C. to initiate polymerization. When the reaction was carried out for 1.5 hours, N 2 Replace CO in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com