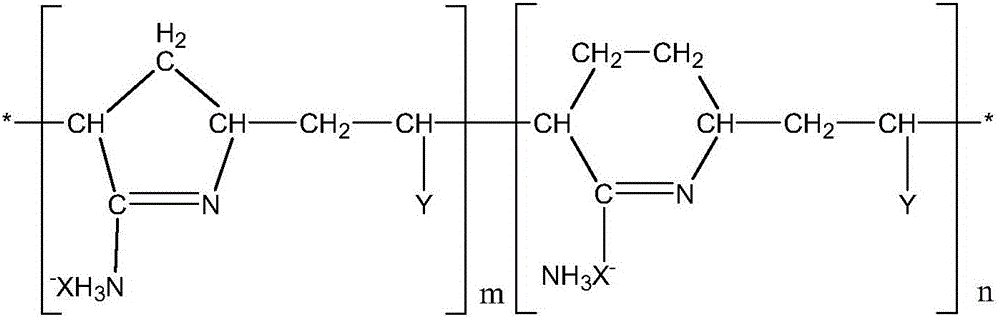

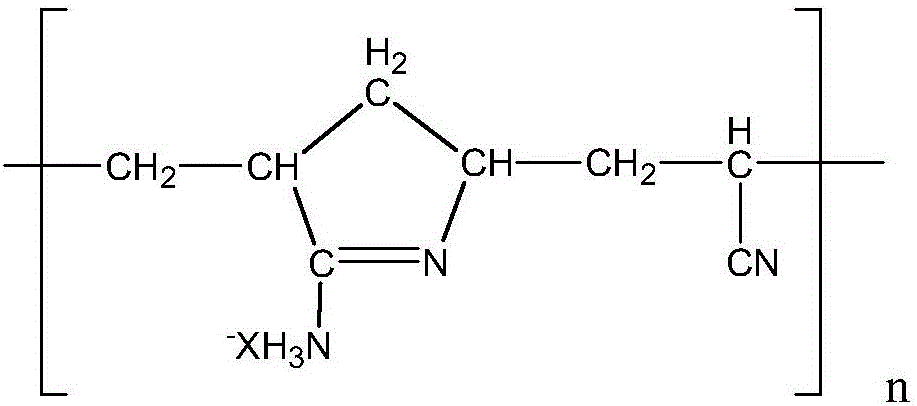

Method for supercritical synthesis of cationic polyamidine flocculating agent

A cationic polymerization and supercritical technology, applied in the direction of flocculation/sedimentation water/sewage treatment, bulk chemical production, etc., can solve the problems of multiple temperature conditions of impurities, poor effect, low yield, etc., and achieve high purity of polyamidine , wide application range, high molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

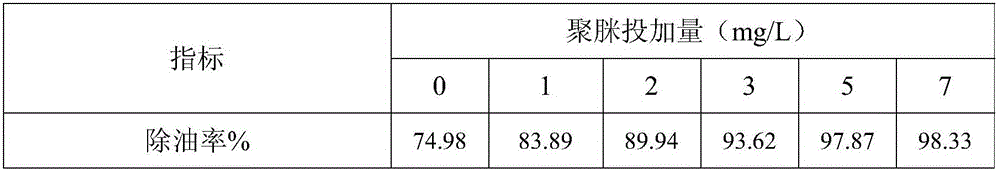

Examples

Embodiment 1

[0038] A method for supercritical synthesis of cationic polyamidine flocculants, the steps are as follows:

[0039]1. Measure 3.4mL of NVF and 3.1ml of AN in the supercritical reactor, pass nitrogen gas for 15min to remove oxygen, add 5mL of 0.3% AIVN methanol solution, close the reactor and connect it to the carbon dioxide pipeline for flushing, and discharge the air. Put the device in a constant temperature box, set the constant temperature to 55°C, fill with carbon dioxide gas, pressurize to 15MPa, make the carbon dioxide enter a supercritical state, and react for 30 minutes. Reduce the pressure and discharge carbon dioxide to obtain a copolymer.

[0040] 2. Add the copolymer to 8mL of concentrated hydrochloric acid and 20g of ultrapure water, place it in an oil bath at 100°C and continue stirring for 4 hours to prepare polyamidine. After cooling, the obtained product was washed with acetone solution to precipitate a solid product, which was placed in a vacuum oven and dri...

Embodiment 2

[0042] With the method for the supercritical synthesis cationic polyamidine flocculant described in embodiment 1, difference is:

[0043] Step (1) The constant temperature is 50°C, filled with carbon dioxide gas, and pressurized to 20MPa;

[0044] Step (2) The copolymer was added to 8 mL of concentrated hydrochloric acid and 20 g of ultrapure water, placed in an oil bath at 110° C. and continuously stirred for 4 h.

Embodiment 3

[0046] With the method for the supercritical synthesis cationic polyamidine flocculant described in embodiment 1, difference is:

[0047] Step (1) The constant temperature is 60°C, filled with carbon dioxide gas, and pressurized to 18MPa;

[0048] Step (2) The copolymer was added to 8 mL of concentrated hydrochloric acid and 20 g of ultrapure water, placed in an oil bath at 105° C. and continuously stirred for 5 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com