Preparation method of starch grafting concrete thickener

A technology of starch grafting and concrete, which is used in the preparation of concrete thickeners and starch graft concrete thickeners, and can solve the problems of reduced concrete performance, prolonged initial and final setting times, and concrete slump Reduce and other problems, achieve good adaptability, simple and convenient operation steps, and improve the effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

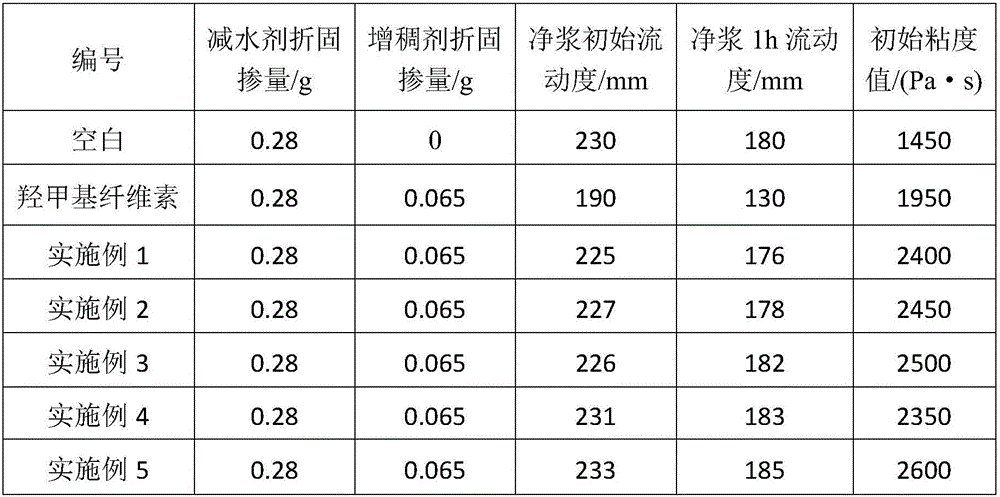

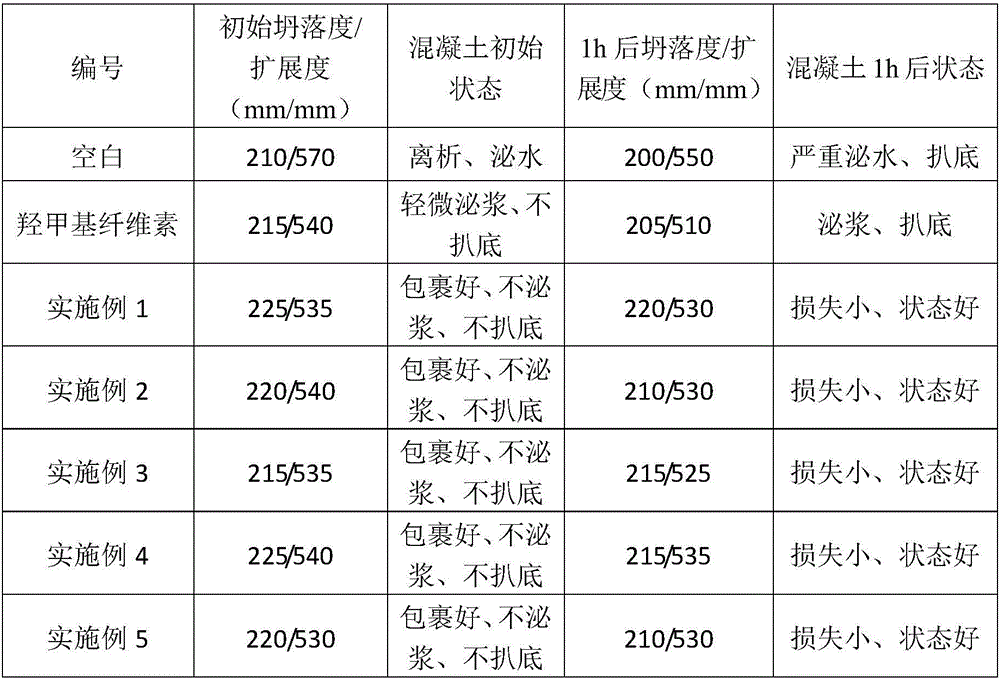

Examples

Embodiment 1

[0024] 1) Dissolve 65 g of tapioca starch in water, stir to prepare a starch solution with a concentration of 25% by mass, heat at 69°C to gelatinize, add 0.51 g of cerium ammonium nitrate, and react for 1.5 hours to obtain a starch free radical solution;

[0025] 2) Add 20 g of isopropyl acrylamide and 4 g of sodium allyl sulfonate into the reactor under the condition of 36°C, stir evenly, and then dropwise add 2.8 g of potassium persulfate and 0.9 g of isoascorbic acid. Aqueous solution, reaction time 3h, to obtain starch graft;

[0026] 3) After the reaction is completed, it is washed with ethanol, filtered by suction, dried, adjusted to pH 6 with sodium hydroxide, and added with water to obtain a starch graft concrete thickener with a concentration of 15% by mass.

Embodiment 2

[0028] 1) Dissolve 25g of corn starch in water, stir to prepare a starch solution with a concentration of 30% by mass, heat at 51°C to gelatinize, add 0.30g of potassium permanganate, and react for 1h to obtain a starch free radical solution;

[0029] 2) At 60℃, add 20g of acrylamide and 15g of sodium methallyloxysulfonate into the reactor, stir evenly, and then add 1.1g of ammonium persulfate and 0.21g of sodium ascorbate respectively. Aqueous solution, reaction time 4h, to obtain starch graft;

[0030] 3) After the reaction is completed, it is washed with ethanol, filtered by suction, dried, adjusted to pH 6 with sodium hydroxide, and added with water to obtain a starch graft concrete thickener with a concentration of 20% by mass.

Embodiment 3

[0032] 1) Dissolve 39 g of potato starch in water, stir to prepare a starch solution with a concentration of 15% by mass, heat it at 70°C for gelatinization, add 0.195 g of benzoyl peroxide, and react for 2 hours to obtain a starch free radical solution;

[0033] 2) At 46℃, add 20g of N-vinylpyrrolidone and 8g of 2-acrylamido-2-methylpropanesulfonic acid into the reactor, stir evenly, and then add 2.9g and 1.2g of hydrogen peroxide dropwise respectively. An aqueous solution of sodium bisulfate, reaction time 2h, to obtain starch grafts;

[0034] 3) After the reaction is completed, it is washed with ethanol, filtered by suction, dried, adjusted to pH 7 with potassium hydroxide, and water is added to obtain a starch graft concrete thickener with a mass percentage concentration of 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com