Novel crosslinked alkaline polyarylether anion exchange membrane as well as preparation method and application thereof

An anion-exchange membrane and polyarylether technology, applied in the field of cross-linked polyarylether compounds, can solve the problems of poor alkaline stability and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

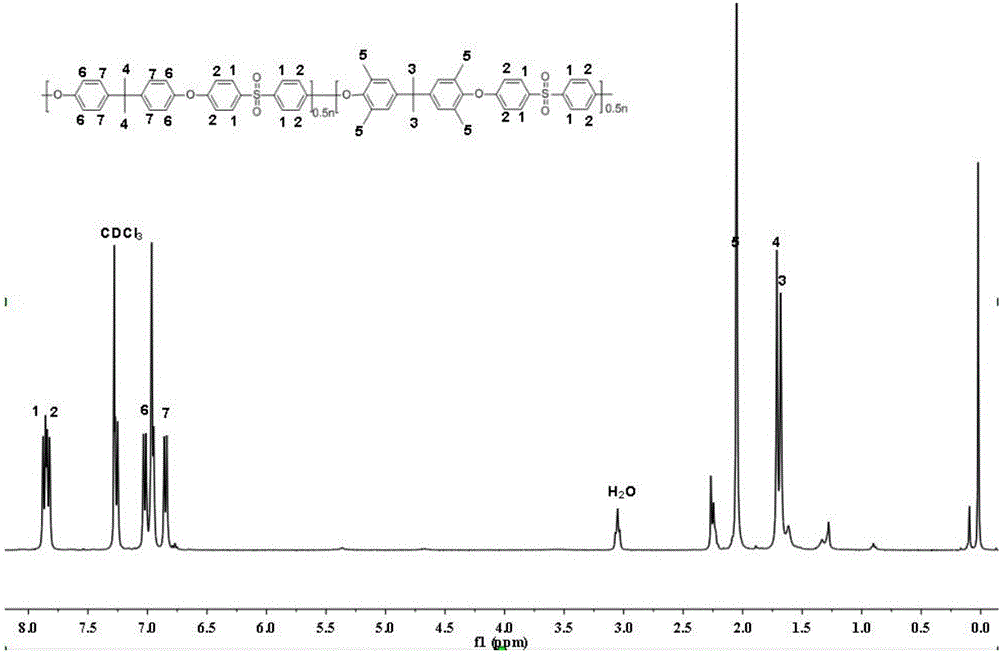

Embodiment 1

[0114] (1), preparation of random polyarylether compound: 10mmol of tetramethylbisphenol A (formula 19), 1mmol of bisphenol A (formula 22), 11mmol of 4,4'-difluorodiphenyl sulfone (formula 28), add 22mmol of potassium carbonate, 30mL of toluene and 20mL of sulfolane, nitrogen protection, bring water at 140°C for 2h, then raise the temperature to 210°C for 3h, pour the reaction solution into a beaker containing 300mL of methanol and stir to precipitate, And using methanol and deionized water and repeated washing, vacuum drying at 80 ° C to obtain a gray polymer resin, and the structure of the prepared polyarylether compound was characterized by hydrogen nuclear magnetic resonance, as shown in figure 1 As shown, the molecular weight of the prepared random polyarylether compound measured by GPC is 68kg / mol, and the structure is as follows:

[0115]

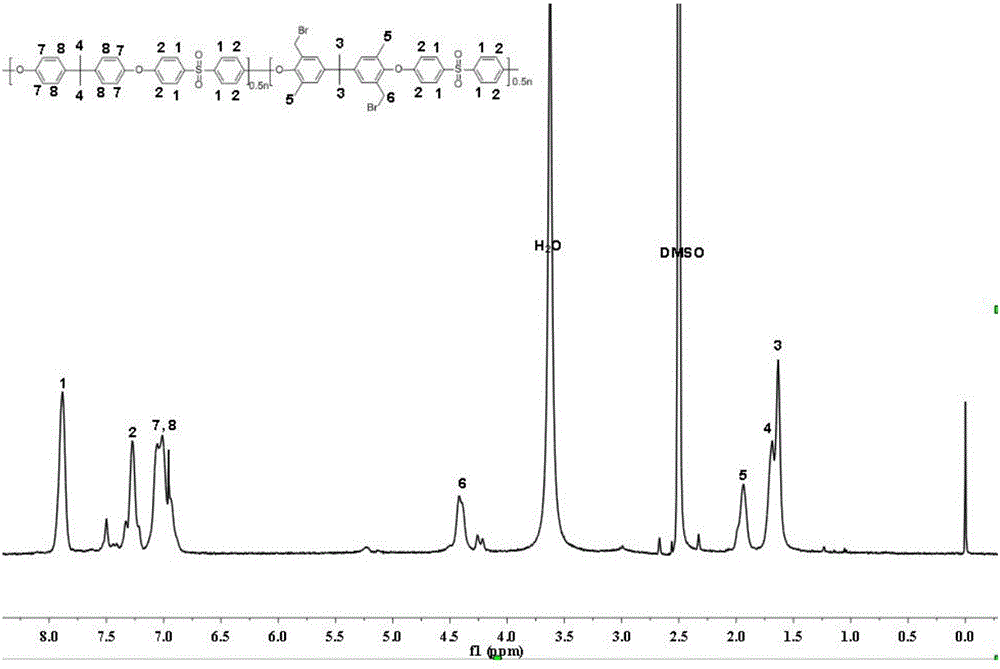

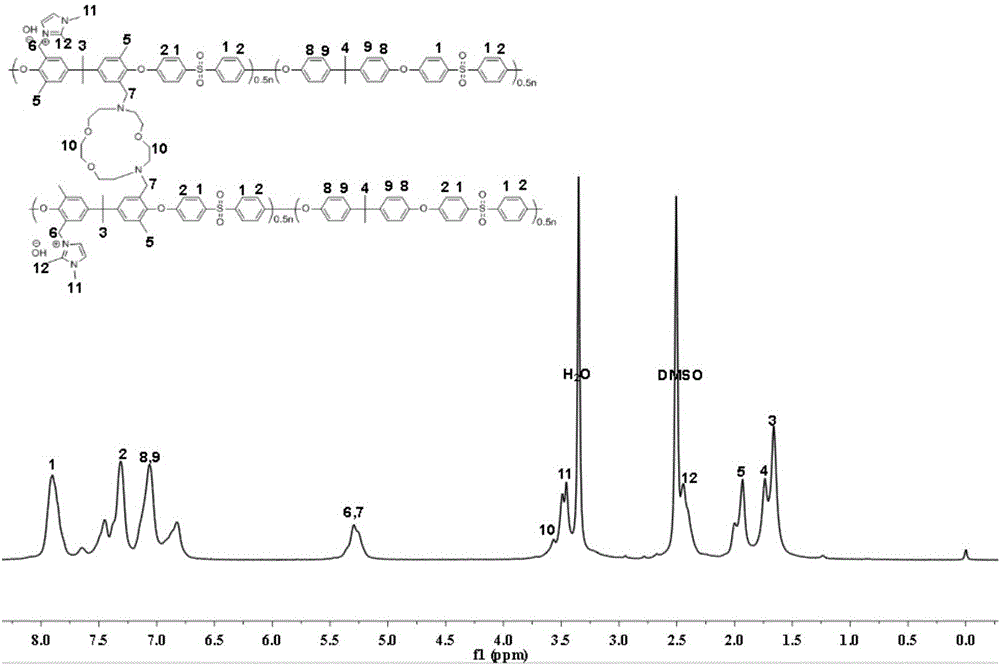

[0116] (2) Bromomethylation: Take 0.01mmol of random polyarylether, dissolve it in 20mL of 1,1,2,2,-tetrachloroethane, add 0.035...

Embodiment 2

[0127] (1) Preparation of random polyarylether compounds: 3mmol tetramethylbiquinone (formula 20), 7mmol bisphenol AF (formula 23), 10mmol 4,4'-difluorodiphenyl sulfone (formula 28), Add 20mmol of sodium carbonate, 20mL of toluene and 20mL of N,N-dimethylacetamide, nitrogen protection, bring water at 140°C for 2.5h, then raise the temperature to 165°C for 12h, pour the reaction solution into a container containing 300mL of methanol Stir and precipitate in a beaker, wash with methanol and deionized water repeatedly, and dry under vacuum at 80°C to obtain a gray polymer resin. The molecular weight of the prepared random polyarylether compound is 62kg / mol, and the nuclear magnetic resonance hydrogen Spectra characterized the structure of the prepared polyarylether compound, the structure is as follows:

[0128]

[0129] In the formula, Ar 1 For formula (20), Ar 3 is formula (10)

[0130] (2) Bromomethylation: Take 0.01mmol (0.62g) of random polyarylether, dissolve it in 20m...

Embodiment 3

[0140] (1) Preparation of random polyarylether compounds: 2mmol tetramethylbisphenol fluorene (formula 21), 8mmol p-hydroxycatechol (formula 24), 4,4'-difluorodiphenyl sulfone (10mmol), Add 20mmol of cesium carbonate, 10mL of toluene and 20mL of N,N-dimethylformamide, under nitrogen protection, bring water at 140°C for 3h, then raise the temperature to 150°C for 16h, pour the reaction solution into a tank containing 300mL of methanol Stir and precipitate in a beaker, wash with methanol and deionized water repeatedly, and dry under vacuum at 80°C to obtain a gray polymer resin. The molecular weight of the prepared random polyarylether compound is 52kg / mol, and the H NMR spectrum The structure of the prepared polyarylether compound was characterized, and the structure is as follows:

[0141]

[0142] In the formula, Ar 1 For formula (32), Ar 3 is formula (11)

[0143] (3) Bromomethylation: Take 0.01mmol (0.52g) of random polyarylether, dissolve it in 20mL of 1,1,2,2,-tetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com