Device for preparing toluylene bis(triazinyl) particular fluorescent whitening agent and preparation method thereof

A fluorescent whitening agent and bis-triazine technology, applied in styrene-based dyes, chemical instruments and methods, organic dyes, etc., can solve the problems of complex wastewater treatment procedures, high engineering investment, and poor biodegradability, and achieve Improve the reaction effect, simplify the process, accelerate the effect of dissolution and reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

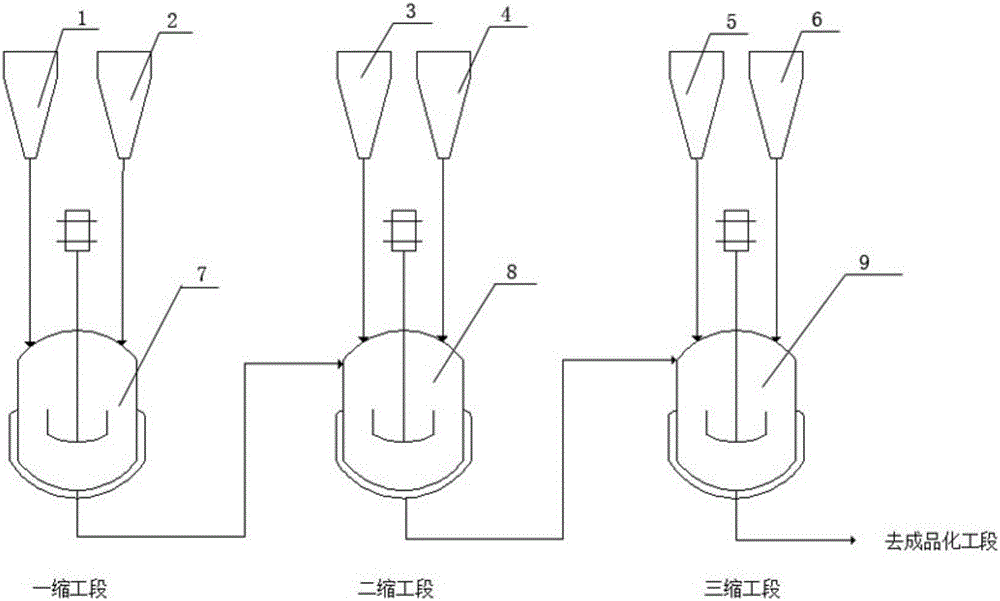

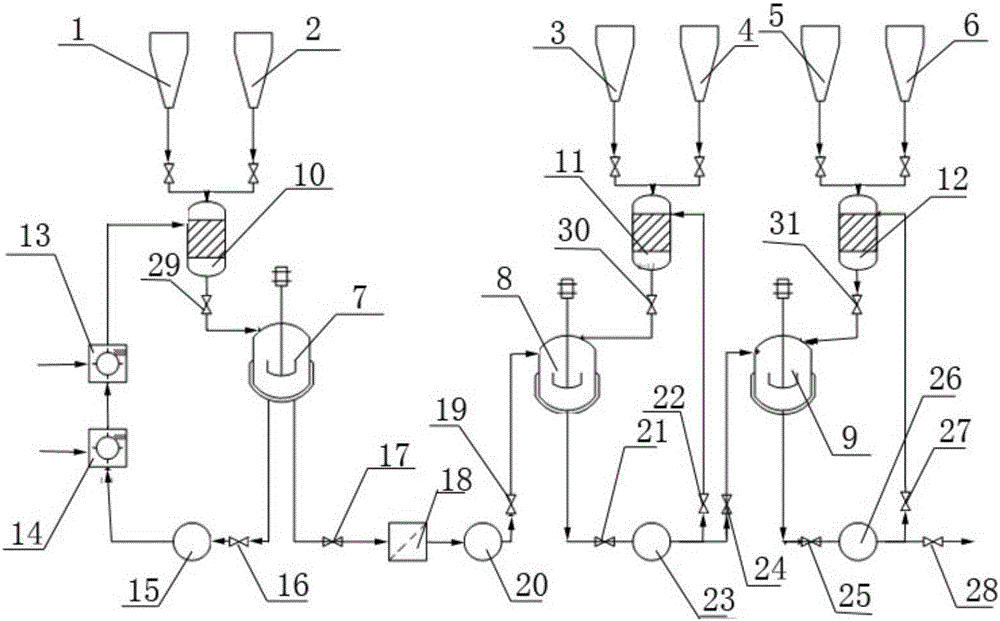

[0020] A device for preparing stilbene bistriazine granular fluorescent whitening agents, including three shrinking sections, a second shrinking section, and a third shrinking section; the first shrinking section includes a first reactor connected in a sequential cycle, a The water pump, the DSD acid homogenizer, the cyanuric chloride homogenizer, the first circulation channel formed by the first reaction chamber, the first acid-binding agent metering tank and the crushed ice metering tank are connected to the first reaction chamber; the second shrinkage section includes the sequence The second circulation channel formed by the connected second reaction kettle, the second water pump, and the second reaction chamber, the second acid-binding agent metering tank and the second shrinkage raw material metering tank are connected to the second reaction chamber; the third shrinkage section includes a sequentially connected third The third circulation channel formed by the reaction ket...

Embodiment 2

[0022] A method utilizing the device in Example 1 to prepare stilbene bistriazine granular fluorescent whitening agent, under stirring, 1300kg of water and 2300kg of borneol were added to the 15m 3 After mixing in the first reaction chamber, start the first water pump, let the first circulation channel be filled with 0 ℃ ice-water mixture, turn on the power supply of DSD acid homogenizer and cyanuric chloride homogenizer, and 1000kgDSD acid powder required for the reaction and 1000kg of cyanuric chloride are added to their respective homogenizers for high-speed grinding and dispersion. The ice water in the loop first flows through the DSD acid homogenizer, then through the cyanuric chloride homogenizer, and then through the 250L first reaction room, when the material reaches the first reaction chamber, open the high level tank valve of the soda ash solution (the first acid-binding agent metering tank), add the soda ash solution dropwise to the first reaction chamber, control th...

Embodiment 3

[0025] A method utilizing the device in Example 1 to prepare stilbene bistriazine granular fluorescent whitening agent, under stirring, 1300kg of water and 2300kg of borneol were added to the 15m 3 After mixing in the first reaction chamber, start the first water pump, let the first circulation channel be filled with 0 ℃ ice-water mixture, turn on the power supply of DSD acid homogenizer and cyanuric chloride homogenizer, and 1000kgDSD acid powder required for the reaction and 1000kg of cyanuric chloride are added to their respective homogenizers for high-speed grinding and dispersion. The ice water in the loop first flows through the DSD acid homogenizer, then through the cyanuric chloride homogenizer, and then through the 250L first reaction room, when the material reaches the first reaction chamber, open the high level tank valve of the soda ash solution (the first acid-binding agent metering tank), add the soda ash solution dropwise to the first reaction chamber, control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com