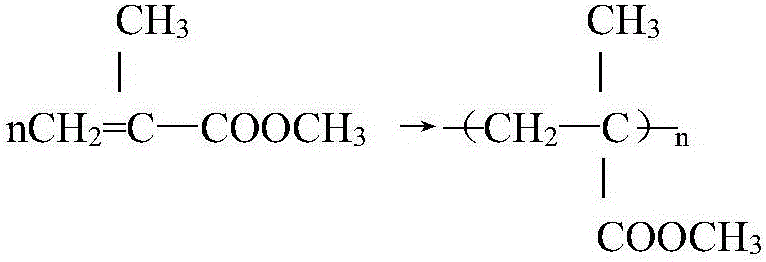

MMA (methyl methacrylate)-based colored anti-slip thin-layer paving material and preparation process thereof

A technology of methacrylic acid and n-butyl methacrylate, used in anti-corrosion coatings, multi-color effect coatings, anti-fouling/underwater coatings, etc., can solve the problem of poor high temperature resistance, easy chalking, and low tensile strength and other problems, to achieve the effect of excellent anti-ultraviolet aging performance, overall uniformity, environmental protection and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

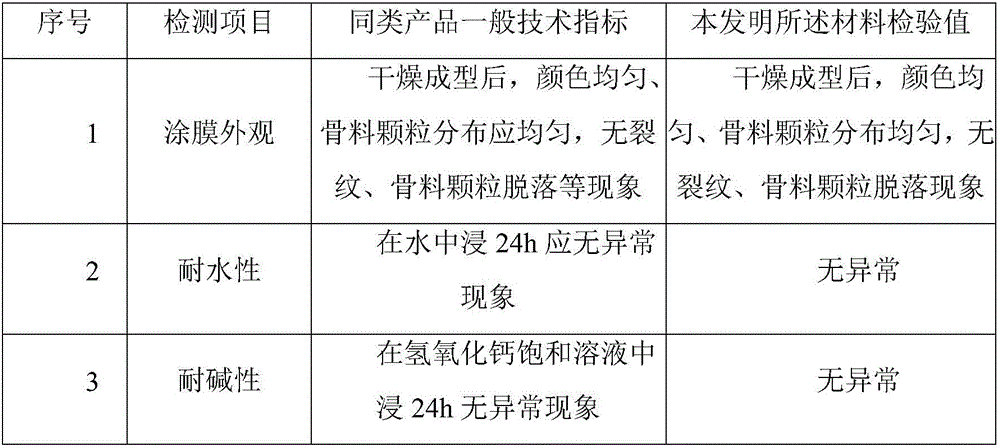

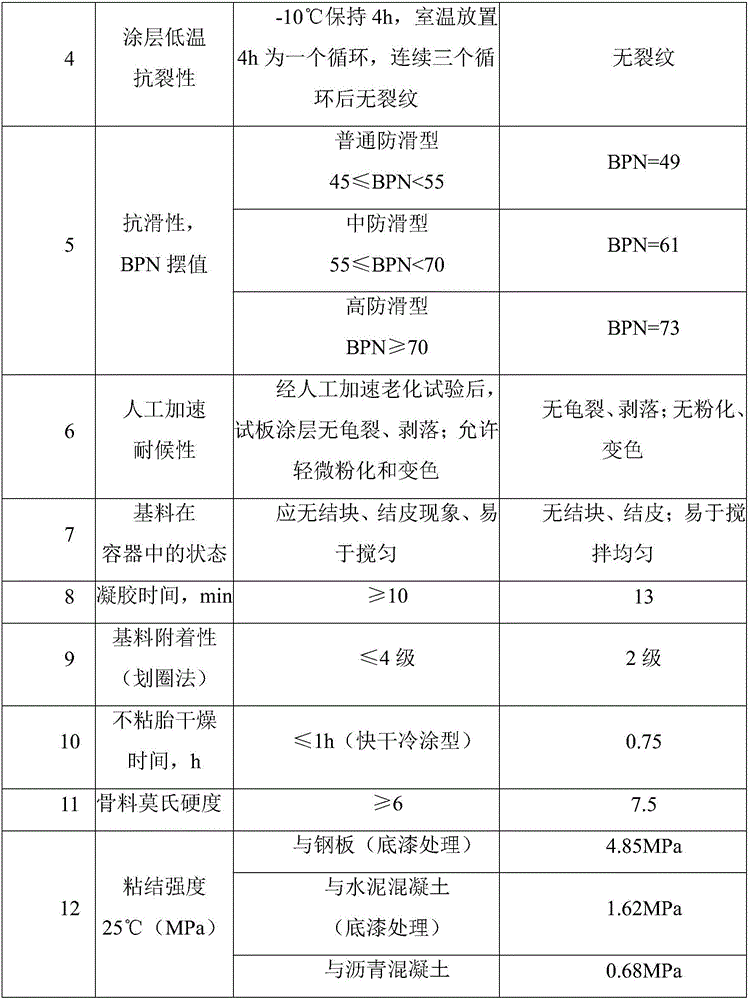

[0039] Embodiment 1: A kind of colored non-slip thin-layer pavement material based on methacrylic resin MMA is made of the following raw materials in mass percentage: modified methacrylic resin 40%, n-butyl methacrylate 10%, acrylic acid iso 4.5% octyl ester, 5.2% fumed silica, 2.5% styrene, 1.6% high boiling point paraffin, 3.4% bifunctional ethylene-propylene composite dispersant, 9.5% calcium filler, 16% high hardness natural mineral filler, 0.8% of N-N-dimethyl-p-hydroxyaniline, 2.5% of cross-linking agent BPO, and 4% of resin-based color paste, wherein N-N-dimethyl-p-hydroxyaniline and cross-linking agent BPO are reaction stimulating substances.

Embodiment 2

[0040] Embodiment two: a kind of colored non-slip thin-layer paving material based on methacrylic resin MMA is made of the following raw materials in mass percentage: modified methacrylic resin 32%, n-butyl methacrylate 12%, acrylic acid iso 3% octyl ester, 5.5% fumed silica, 3.2% styrene, 2.2% high boiling point paraffin, 3.6% bifunctional ethylene-propylene composite dispersant, 10% magnesium filler, 24% high hardness natural mineral filler, N-N-dimethyl-p-hydroxyaniline 0.65%, cross-linking agent BPO 1.2%, resin-based color paste 2.65%.

[0041] A kind of preparation technology of the colored non-slip thin-layer pavement material based on methacrylic resin MMA, pre-wetting and dispersing the fumed silica, high-boiling point paraffin, and resin-based color paste respectively according to 10% concentration, and the wetting and dispersing raw materials are N-butyl methacrylate; dilute N-N-dimethyl-p-hydroxyaniline at 5% concentration, diluent is isooctyl acrylate; modify metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com