Preparation method of black low-infrared-emissivity material

A low-infrared emission, black technology, used in fire-retardant coatings, camouflage coatings, coatings, etc., can solve the incompatibility of physical and mechanical properties and construction performance with low emissivity, difficult processing of low-infrared emissivity materials, and insufficient color varieties. problem, to achieve good thermal infrared stealth effect, reduce recognition ability, and eliminate the effect of typical contour features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a black low infrared emissivity material, the steps are as follows:

[0023] 1. Experimental part

[0024] 1. Experimental raw materials: use aluminum hydroxide [molecular formula Al(OH) 3 ], phosphoric acid (molecular formula H 3 PO 4 ), chromium trioxide (molecular formula CrO 3 ), methanol (molecular formula CH 3 OH), manganese dioxide powder and water (which can be ultrapure water, distilled water or deionized water) are used as raw materials for experiments, and each experimental raw material is provided by Chengdu Kelong Chemical Reagent Factory;

[0025] 2. Experimental instruments: The models and manufacturers of the experimental instruments used in the synthesis experiment and sample characterization process are shown in Table 1 below.

[0026] Table 1: Main Experimental Instruments

[0027] name model Instrument provider Electronic balance FA-1004 Shanghai Sunny Hengping Scientific Instrument Co., Ltd. ...

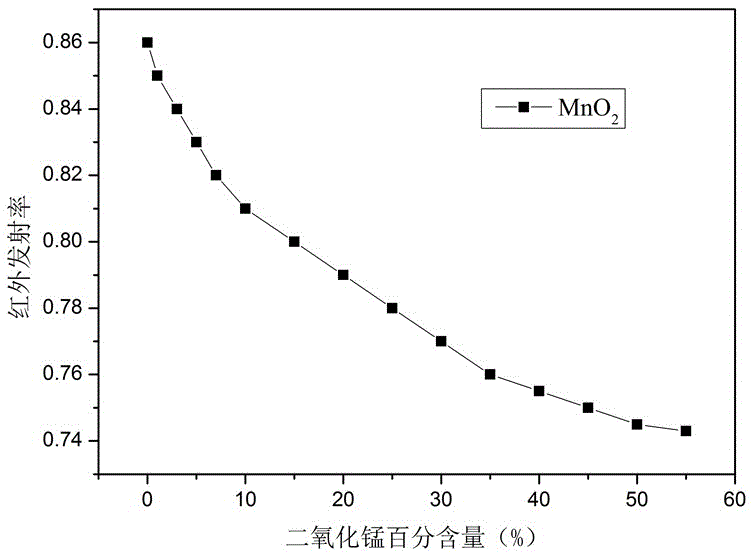

Embodiment 2~14

[0038] A method for preparing a black low-infrared emissivity material. In Examples 2 to 14, the amount of manganese dioxide powder in the step b of preparing the black low-infrared emissivity material corresponds to: 1g, 3g, 5g, 7g, 10g, 15g, 20g, 25g, 30g, 35g, 40g, 45g, 50g and 55g; others are the same as in Example 1, omitted.

Embodiment 15

[0040] A method for preparing a black low-infrared emissivity material, the steps are: take 100 parts by mass of chromium aluminum phosphate, place it in a reactor and heat it to 75°C, then add 1 part by mass of manganese dioxide powder, react for 35 minutes under stirring, and then put After the reaction, the material was heated to 175°C and kept for 3.5 hours to react for 3.5 hours, and a black low-infrared emissivity material (or called: MnO 2 - chromium aluminum phosphate based low infrared emissivity material).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com