Water white resistant particle crosslinking type water-in-water multicolor paint

A multi-color paint, cross-linking technology, applied in the field of paint, can solve the problems of water and white resistance, poor corrosion resistance, scratch resistance, etc., to achieve the effect of achieving stability and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

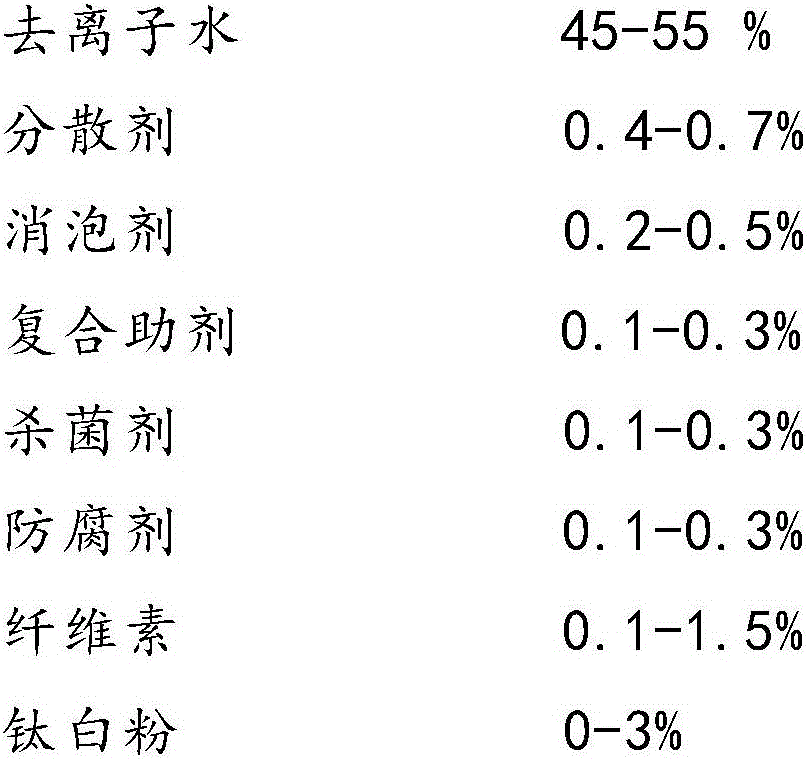

[0037] 1. Disperse phase

[0038]

[0039] 2. Protective glue solution

[0040]

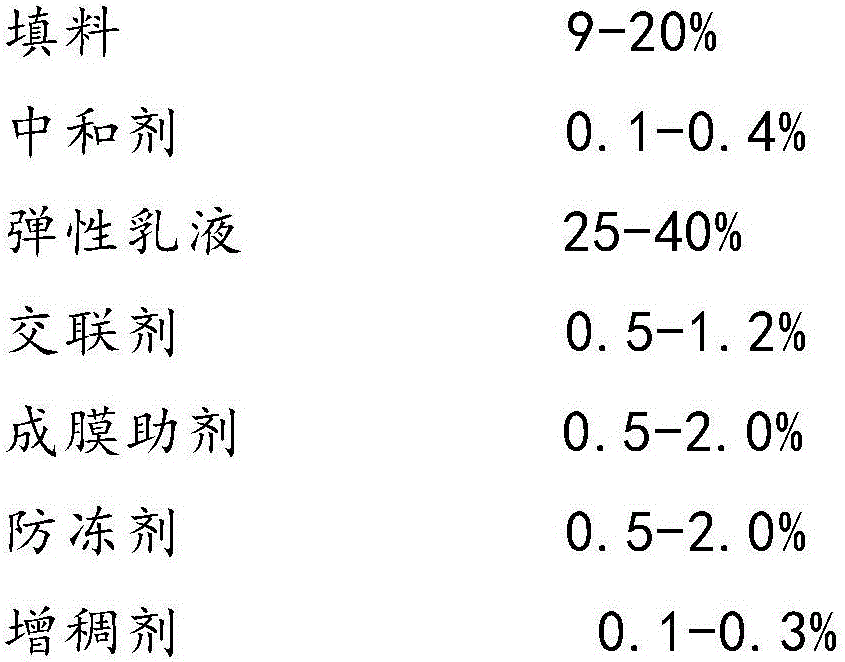

[0041] 3. Continuous phase

[0042]

[0043] 4. The mass mixing ratio of dispersed phase, protective colloid solution and continuous phase is: 40:30:30

[0044] In this example:

[0045] First, the dispersed phase, the protective colloid solution and the continuous phase were produced respectively according to the formula given in the above-mentioned examples;

[0046]Secondly, granulate the prepared dispersed phase in the protective colloid solution according to the mass ratio to obtain the required colored particles;

[0047] Finally, the prepared colored particles are uniformly mixed with the continuous phase according to the mass ratio to prepare the water-white particle-resistant cross-linked water-in-water multicolor paint.

[0048] The water-whitening-resistant particle cross-linked water-in-water multi-color coating given in this example is tested, and it has outstanding stre...

Embodiment 2

[0050] 1. Disperse phase

[0051]

[0052]

[0053] 2. Protective glue solution

[0054]

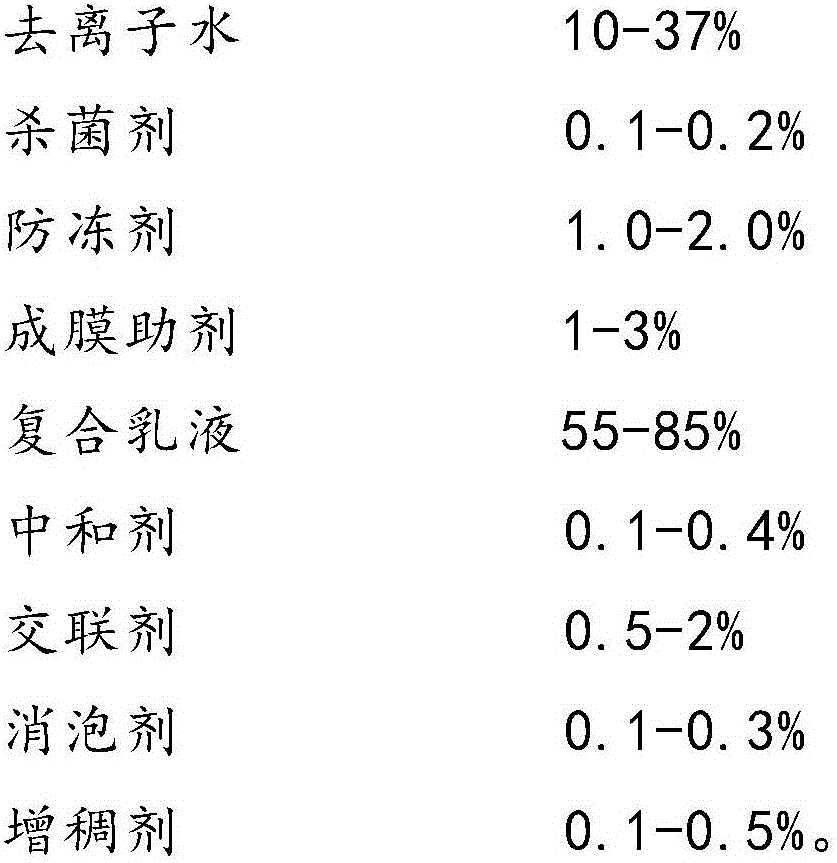

[0055] 3. Continuous phase

[0056]

[0057]

[0058] 4. The mass mixing ratio of dispersed phase, protective colloid solution, and continuous phase is: 45:30:25

[0059] In this example:

[0060] First, according to the formula given in the above examples, the dispersed phase, the protective glue solution and the continuous phase were produced respectively;

[0061] Secondly, granulate the prepared dispersed phase in the protective colloid solution according to the mass ratio to obtain the required colored particles;

[0062] Finally, the prepared colored particles are uniformly mixed with the continuous phase according to the mass ratio to prepare the water-white particle-resistant cross-linked water-in-water multicolor paint.

[0063] The water-whitening-resistant particle cross-linked water-in-water multi-color coating given in this example is tested, and it also h...

Embodiment 3

[0065] 1. Disperse phase

[0066]

[0067]

[0068] 2. Protective glue solution

[0069]

[0070] 3. Continuous phase

[0071]

[0072] 4. The mass mixing ratio of dispersed phase, protective colloid solution and continuous phase is: 35:30:35

[0073] The preparation method of the water-in-water particle-resistant cross-linked water-in-water multi-color paint given in this example is the same as that of the first and second examples above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com