Method for leaching niobium, scandium and rare earth elements from tailings

A rare earth element and leaching technology, which is applied in the field of scandium and rare earth element and niobium leaching, can solve the problems of high impurity content, difficulty in solid-liquid separation, low leaching rate, etc., and achieve lower reaction temperature, low process cost and fast leaching speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

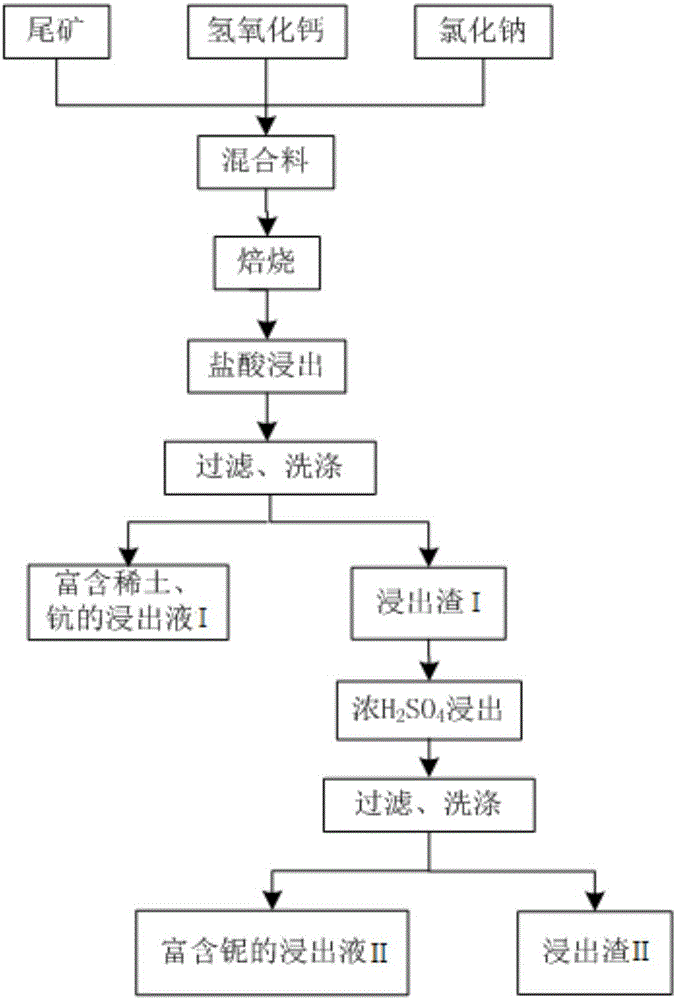

[0038] Such as figure 1 As shown, embodiment 1 provides a method for leaching niobium, scandium and rare earth elements from tailings, wherein the raw materials are selected from the tailings of iron, rare earth and fluorite in Baiyan Obo Mine, wherein the main rare metals include niobium , scandium, and a small amount of rare earths not recovered in the previous rare earth flotation process. The contents of niobium, scandium and rare earth in the tailings are as follows: w(Nb 2 o 5 )=0.36%, w(Sc 2 o 3 )=0.03%, w(REO)=2.4%.

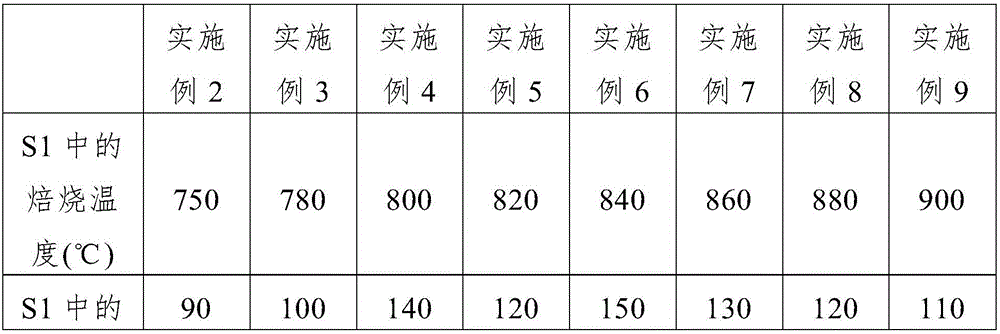

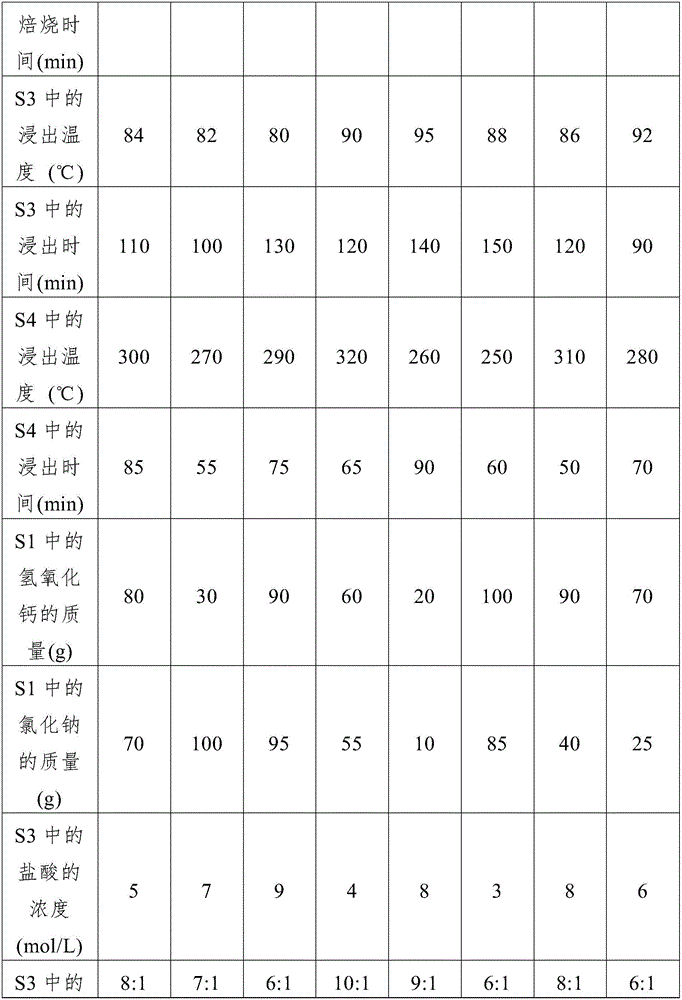

[0039] S1. Take 100 g of the above tailings, add 50 g of calcium hydroxide and 30 g of sodium chloride, mix the three evenly to obtain a mixture, and roast the mixture at 800° C. for 120 minutes to obtain roasted ore.

[0040] S2. Perform ball milling on the roasted ore by ball milling equipment, and ensure that the amount of ore whose grinding particle size is less than or equal to 75 μm in the roasted ore after the ball milling treatment is not les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com